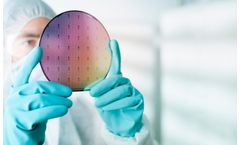

cleanroom manufacturing Applications

3 applications found

-

Premium

Monitors, gas analyzers solutions for ISO 14644-1/2: 2015 insights & solutions

ISO 14644-1:2015 continues to pose challenges to cleanroom managers and manufacturers. Here ...

By Particle Measuring Systems (PMS) based in Boulder, COLORADO (USA).

-

Gas Monitoring Solutions for Cleanroom

of contamination. The quality of air within a cleanroom is critical. Whether it be for the ...

By Gasera Ltd based in Turku, FINLAND.

-

Gas Analysers for Semiconductor Industry

The importance of cleanrooms in the electronic industry. Air purity is essential for ...

By ETG Risorse e Tecnologia S.r.l. based in Chivasso (TO), ITALY.

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you