Showing results for: power monitoring system Applications

-

Premium

Continuous emissions monitoring solutions for power plants

OPSIS offers fully automated system solutions for continuous monitoring in power ...

By OPSIS AB based in Furulund, SWEDEN.

-

Premium

Emissions Monitoring for Power Plants

Opsis offers fully automated system solutions for continuous monitoring in power ...

By OPSIS AB based in Furulund, SWEDEN.

-

Premium

Static and rotary torque sensors solutions for government sector

agencies on the compact shaft power measurement system which allows them to accurately measure and ...

By Datum Electronics Ltd based in East Cowes, UNITED KINGDOM.

-

Fire detection solutions for the power stations sector

One of the main hazards in a power station is a fire in a coal rich environment; the latter ...

By Codel - a Forbes Marshall company based in Bakewell, UNITED KINGDOM.

-

Ozone solutions for wastewater treatment sector

the first injected-ozone disinfection system in Canada at the Town of Cobourg. The ultimate ...

By Aclarus Ozone based in Peterborough, ONTARIO (CANADA).

-

Power Plant & Power Station Emissions Monitoring

for Procal CEM systems. Throughout this period, there has been increasing environmental scrutiny and ...

By Procal - Parker Hannifin Corp based in Peterborough, UNITED KINGDOM.

-

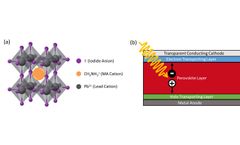

Measuring Charge Carrier Lifetime in Halide Perovskite Using Time-Resolved Photoluminescence Spectroscopy

spectroscopy is shown to be a powerful tool for ...

By Edinburgh Instruments - TECHCOMP Group based in , UNITED KINGDOM.

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you