food process water Articles

-

Where Can Stainless Steel Clad Plate Be Used?

The applications of stainless steel cladding plates can be seen everywhere in our daily lives. It generally involves petroleum, chemistry, food processing, automobiles, water conservancy, electricity, coal & coking, aviation, and other industries. Here are some specific examples for your reference: 1. Shipbuilding and hull structure, 2. Bridge deck system and oil refining, 3. Facade curtain ...

-

Online waste water monitoring system on golfcourse

Validation of BACTcontrol as an online waste water Monitoring System and Microbiological Early Warning System. The presence of dangerous micro organisms in water used in food processing or surface water can be a real threat for human health. The constant monitoring and control of the presence of such dangerous pathogens is therefore of big importance. In a collaboration project between a local ...

-

Online waste water monitoring system on golfcourse - Case Study

Validation of BACTcontrol as an online waste water Monitoring System and Microbiological Early Warning System. The presence of dangerous micro organisms in water used in food processing or surface water can be a real threat for human health. The constant monitoring and control of the presence of such dangerous pathogens is therefore of big importance. In a collaboration project between a ...

-

Monitoring of reservoir feed for hydrocarbon contamination - Case Study

APPLICATION Monitoring of rural watercourse feeding a small reservoir to detect contamination from farm or food processing facilities. CUSTOMER Water Company, SW England PROBLEM Persistent small contamination events had put the reservoir which feeds a drinking water treatment plant at risk. Low level contamination preceded a large event in late ...

-

Helping Prevent Foodborne Outbreaks with Ozone Technology

More consumers are adding fresh fruits and vegetables to their diets and placing more emphasis on “farm to fork” making it critical for retailers to ensure foods within produce areas are free of harmful microorganisms and safe for consumption. Foodborne outbreaks from produce have been on the rise. E.Coli contaminated melons, lettuce, tomatoes, and other produce have caused ...

-

Moisture Measurement is Crucial in Food Processing Operations & Here’s Why

Provide 100% Increase in Production Eciency and Product Inspection Moisture is important in any manufacturing process, but when it comes to food processing, excess moisture can ruin products and create excess waste. And what is worse than a wasted eort? Economical losses and decreased productivity. With continuous online moisture measurement, food production plants will nd huge money savings. ...

-

Innovative Water Solutions for the Food/Beverage Processing Industry

With the growing international and local pressure, the Food and Beverage industry has to find new ways in its product development as well as minimizing costs and health risks. Sustainability has become an important issue in the evolving Food and Beverage industry. Companies are being required by industries and government agencies to better utilize their water consumption to minimize their ...

-

Drinking Water Storage Tanks

Utilizing Glass-Fused-to-Steel tank as a drinking water storage tank is one of the most widely-applied application within Center Enamel Co., Ltd till to now. Our Glass-Fused-to-Steel tank is certificated and approved by NSF/ ANSI 61. Center Enamel already become enameling expert after 30 years enameling products' production, and we successfully made innovative development of anti-microbial ...

-

In Search of Ideal Groundwater Treatment

As surface water supplies become increasingly polluted and difficult to treat, the use of groundwater continues to increase. Every day, more than 77 billion gal of water are withdrawn from aquifers for a variety of uses including human consumption. Worldwide, groundwater makes up 95% of available freshwater, and nearly half of the U.S. population receives all or part of its drinking water from ...

-

Fluoropolymers and the future of bandages

NASA is working on a new type of bandage that can dramatically increase recovery time for those who are wounded. Most people know that blood flow is essential to the wound healing process. Heat is one way to increase the amount of blood flow to the skin. However, in many applications, access to warm water or a heating pad is impossible. Obviously, space would be one environment where access to ...

By Fluorostore

-

World Food Day 2023: Water is life, water is food

Water is vital for life on Earth. It covers most of the planet’s surface, forms more than 50% of our bodies, and is the basis of our food supply. However, it is a unique and irreplaceable resource whose quantity is limited. There are few places where water is accessible in adequate amounts to meet people’s needs. Water was, and still is, essential for agricultural ...

-

How is Reverse Osmosis Desalination Used in Tertiary Sewage Treatment Applications?

Salts and other dissolved solids can be pretty tricky to remove from wastewater streams. Standard filtration doesn’t really do anything about dissolved solids and neither does coagulation or sedimentation. They might manage to remove some, but in situations where total dissolved solids (TDS) are particularly high, those sorts of treatments do not lower TDS enough to be compliant or to reuse ...

-

World Health Organization`s (WHO) Guidelines for drinking-water quality (GDWQ)

The World Health Organization's (WHO) Guidelines for drinking-water quality (GDWQ) were developed with the primary goal of enforcing protection on human health concerning the quality of drinking water. Consequently, it ensures public health is considered during the formulation and implementation of regional and national drinking-water actions and policies. Other objectives include: Providing a ...

-

An overview of reverse osmosis

Reverse osmosis is the separation or filtration method by which many types of molecules and ion particles are removed from the solution through porous membrane-technology filtration. Reverse osmosis systems work very well at removing all types of hard minerals and contaminants in the water. Hard water minerals are easily removed from the reverse osmosis membrane. An amount of pressure is applied ...

-

Thermal Screw Conveyors: Heated or Chilled

Industrial screw conveyors, also known as auger conveyors, are a widely-used method of bulk conveyance in many industries. These industries include food and chemical processing, water treatment plants, biofuel production, agriculture, and more. Besides conveyance, there are added benefits industrial screw conveyors can bring to its users. One of these benefits is the ability to heat or chill the ...

-

BioLargo (BLGO) is a Bargain at Current Levels - Green Technology Investments

BioLargo Inc. (OTCQB: BLGO), developer of Nature's Best Solution - a proprietary version of iodine - formed to help solve a variety of common problems around the world, appears to be a bargain at current levels. From pet supplies like those sold at PetSmart Inc. (NASDAQ: PETM) to household brands like those sold by Clorox Company (NYSE: CLX), the company is targeting a number of different ...

-

What is a check valve and how it works

Check valves are found in almost every industrial application acting as non-return or one-way valves. Generally simple devices, check valves perform a vital function preventing reverse flows, damage and ensuring efficient operations. Reverse flow can, for example, result in water hammer. This phenomenon can see repeated extreme pressure surges in connected pipework, valves and pumps that may ...

-

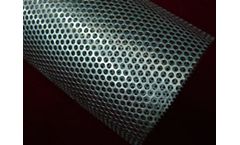

Perforated Metal Tube

Victall is a manufacturer of perforated, spiral wound tubes used for sand control assemblies in oil field down-hole operations & other applications including water treatment, food processing, nuclear energy & pulp & paper. Sand Control Assemblies inclues: Perforated Tubing Perforated Tubing Filters Spiral Welded Metal Tubing Perforated metal tubes are available in diameter up to 6 in. ...

-

How Level Sensors Are Used in Various Industries

From ensuring the smooth flow of production lines to safeguarding the environment, level sensors play a critical role in various industries. Their ability to accurately and reliably measure the level of liquids, solids, and slurries in tanks, silos, and other containers contributes to efficiency, safety, and quality control across diverse sectors. Let's explore how level sensors are utilized in ...

-

Johnson V Wire Screens for Filtration

Johnson wedge wire screens, also known as V wire screen filters or profile wire screens, are indispensable filtration devices widely employed across diverse industrial sectors. These Vee wire screens are designed to effectively separate solid particles from liquids and classify particles based on their size and shape. Their unique construction is characterized by a surface crafted from ...

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you