spray tower Articles

-

Desalination using spray tower and vapour compression refrigeration system

A desalination system using a spray tower and Vapour Compression Refrigeration (VCR) system is proposed for obtaining fresh water from brackish water. In the spray tower, simultaneous heat and mass transfer take place between the brackish water and air, which results in the evaporation of the brackish water and humidification of the air. Fresh water is obtained from the humidified air by ...

-

Stochastic modeling approaches based on neural network and linear–nonlinear regression techniques for the determination of single droplet collection efficiency of countercurrent spray towers

This paper presents a new mathematical model and a two-layer neural network approach to predict the single droplet collection efficiency (SDCE), η d, of countercurrent spray towers. SDCE values were calculated using MATLAB® algorithm for 205 different artificial scenarios given in a large range of operating conditions. Theoretical results were compared with outputs obtained from a two-layer ...

-

Mass flow measurement with SolidFlow 2.0 - Case Study

Application In an opencast mine, brown coal with a very high content of wax is mined. From this coal, raw montan wax is obtained in different process steps. Therefore, the coal is crushed, dried and impinged with an environmentally friendly solvent to separate the wax from the coal. The acquired montan wax is transported into an evaporation system, where it evaporizes in several stages. After ...

By ENVEA

-

Refinery boiler FGD Pemex

A large boiler company required a FGD system for two, 200,000 lbs/hr fuel oil boilers for a refinery in Mexico. Macrotek competed with major air pollution suppliers and succeeded to win the contract. The scope included two spray towers, all auxiliary components, pumping packages, a forced oxidation system, piping, and controls. In addition, integral stacks were included for the overall height of ...

-

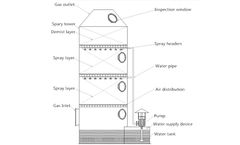

What is a spray tower?

Spray tower, also known as scrubber, wet scrubber, is waste gas treatment equipment. The exhaust gas is fully contacted with the liquid, and the concentration of the waste gas is reduced by using its solubility in water or chemical reaction, so as to become a clean gas that meets the national emission standards. It is mainly used to treat inorganic waste gas, such as sulfuric acid mist, hydrogen ...

-

CFD Analysis of Gas Cooling

In many industrial processes, hot gas is cooled down due to the evaporation (boiling) of sprayed droplets. The effects of two different atomizer types, inner mixing air atomizing nozzles and flow back nozzles, on the cooling behavior inside a spray tower for a typical flue gas are discussed. The heat and mass transfer is computed using computational fluid dynamics (CFD). The interaction between ...

-

Air pollution control for the fertilizer industry in the Middle East - Case Study

Through our subsidiary company, APC Process Engineering, ERG has an impressive track record in the Middle East Fertilizer Production Industry. All our systems come with a performance guarantee backed by more than 30 years of experience successfully treating industrial air pollution around the world. ERG’s systems are used for treating silica, phosphate rock and scale dust, ammonia, ...

-

Hundreds of Options Facing Power Plants Purchasing New or Upgrading

The wet calcium (lime and limestone) process is only one option for removing SO2. Dry systems, ammonium sulfate, seawater, amine and other processes are also alternatives. Assuming that the purchaser has decided to purchase a new or upgrade an existing wet calcium FGD system, he must then make hundreds of decisions about processes and components. These systems represent up to 15 percent of the ...

-

Numerical Simulation of Spray Pattern in a Liquid Flashing Column

Spray columns and towers are fundamental in many industrial applications. Understanding the spray pattern in these dynamic environments is very important in the design of an overall spray system solution. Traditional laboratory physical experiments can be time-consuming, expensive, and sometimes impossible to complete. Computational fluid dynamics (CFD) modeling can be used effectively in this ...

-

Modern Gas Cleaning Techniques For TRS and SO2 Control in the Pulp and Paper Industry

Untitled Document Introduction The control of SO2 and total reduced sulfur (TRS) emissions in the pulp and paper industry can be effectively achieved using the RotaBed™ Fluidized Bed Scrubber*. As the US pulp and paper industry develops and implements strategies to meet the Cluster Rule requirements, particular attention will be paid to the control of both sulfur dioxide (SO2) and ...

-

Introduction of scrubber + activated carbon adsorption exhaust gas purification device

Washing tower + activated carbon adsorption exhaust gas purification device It is suitable for the treatment of waste gas with low concentration and non-single components. The granular dust, smoke and grease can be removed through the water shower tower. The treated waste gas is absorbed by the activated carbon adsorption tower. The function of the water shower tower is to purify the waste gas ...

-

Industrial waste gas treatment system design process

Most industrial manufacturing companies now install environmental protection equipment, and they are more concerned about whether they can meet the standards after installation. There are three points to achieve the standards: 1. Does the manufacturer have this technical strength? 2. Is the product selection correct? 3. Is there any experience in waste gas treatment engineering, or do not ...

-

Wet Scrubbers for Air Pollution Control

A wet scrubber, also known as a "wet scrubber system," is a device used to remove pollutants from industrial and commercial exhaust streams. It is an air pollution control technology that uses a liquid, usually water, to capture and remove pollutants from an airflow. Wet scrubbers are widely used in many industries including power plants, steel mills, chemical plants and refineries. The basic ...

-

Analysis of Sludge Disposal Process and Pollution Control in Urban Sewage Treatment Plant

Based on the sludge incineration and disposal project of an urban sewage treatment plant in Changzhou City, this paper summarizes the main pollution problems and control measures in the process of sludge drying and incineration from the perspective of disposal technology, and provides a reference for the pollution control of similar projects. The wet sludge with moisture ...

-

Mason OH case study

Growing with the Flow Population increase forces Mason, Ohio, to examine biosolids handling process Located in southwest Ohio, between the cities of Cincinnati and Dayton, is the growing metropolis known as Mason. Founded in 1815, Mason has attracted large corporations such as Cintas and Procter & Gamble’s Health Care Research Center. Additionally, on the leisure side, it is home to ...

-

Why we need wet scrubbers for industrial waste gas?

As a commonly used industrial waste gas treatment equipment, the wet scrubber has the advantages of high removal rate and wide application range. In industrial production, various types of waste gas will be produced, and corrosive waste gas also accounts for a large proportion, and these waste gases need to be purified before they can be discharged. There are many purification treatment ...

-

Design calculation of wet scrubber

After receiving the quotation for the wet scrubber, the customer often puts forward the quotation is too high, so many customers do not know the scrubber, but habitually give the conclusion that the price is too high, it seems that something is wrong, the technical team will pass the data Provide detailed basis and configuration of wet scrubber quotation. Affect the wet scrubber ...

-

Wet scrubbers monitor flue gas emissions in a combustion system

Wet scrubbers are considered to be air treatment devices to take away gaseous particulate pollutants (NOx, SOx or other gases produced by combustion systems) that negatively affect the environment. According to air pollution control measures, it is required to take away these particulates in order to protect the receptors from the serious impacts of these gases on the health of humans and ...

-

Washing tower waste gas treatment equipment

Working principle of exhaust gas scrubber The scrubbing tower is also called spray tower and wet scrubber. It consists of four parts: tower body, trays, reboiler and condenser. The scrubber is a device for rough separation, so the number of trays is generally small, usually not more than ten stages. The scrubber is suitable for the separation of mixed gas containing a small amount of dust, the ...

-

Incineration Industry: Scrubber on Sludge Incinerator Reduces Atmospheric Emissions - Case Study

Aberdeen Sewage Treatment Plant in Aberdeen, Washington started up their new Electric Infrared Incinerator in May, 1981. The sewage sludge incinerator, product of Shirco, Inc., needed a pollution control device in order to meet state, local and federal requirements for atmospheric emissions, according to the emissions test on the unit performed January, 1982. Chosen was a Model 24×24- ...

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you