zero discharge effluent treatment Articles

-

Why Zero Liquid Discharge Systems Are Important?

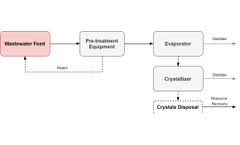

Zero liquid discharge (ZLD) is a strategic wastewater management system that ensures that there will be no discharge of industrial wastewater into the environment. ZLD is achieved by treating wastewater through water recycling and then recovery and reuse for industrial purpose. Hence it is a cycle of closed loop with no discharge. Although ZLD is a costly process, it paves the way for economic ...

By YASA ET

-

Containerized Zero Liquid Discharge Wastewater Treatment Plant by YASA ET

Revolutionizing Wastewater Treatment with Containerized Zero Liquid Discharge Plants (yasa.ltd)Containerized Zero Liquid Discharge (ZLD) wastewater treatment plants are changing the way factories and municipalities manage their wastewater. Zero Liquid Discharge (ZLD) refers to a treatment process in which the plant discharges no liquid effluent into surface waters, in effect completely ...

By YASA ET

-

Paper Industry Wastewater

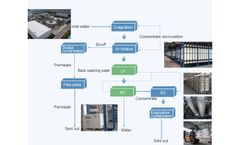

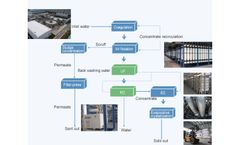

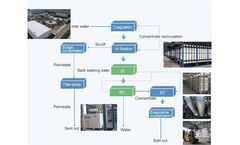

Standard discharge, reclaimed water reuse and zero effluent discharge 1. As for paper mill wastewater treatment, pulping wastewater is the most difficult wastewater to be treated in the papermaking industry. The organic pollutants and inorganic salts are high in content, complex in composition, high in hardness, high in costs. The technical staff of JIUWU work with experts from the Institute of ...

-

Paper Industry Wastewater

Standard discharge, reclaimed water reuse and zero effluent discharge 1. As for paper mill wastewater treatment, pulping wastewater is the most difficult wastewater to be treated in the papermaking industry. The organic pollutants and inorganic salts are high in content, complex in composition, high in hardness, high in costs. The technical staff of JIUWU work with experts from the Institute of ...

-

Paper Industry Wastewater

Standard discharge, reclaimed water reuse and zero effluent discharge 1. Pulping Wastewater is the most difficult wastewater to be treated in the papermaking industry. The organic pollutants and inorganic salts are high in content, complex in composition, high in hardness, high in costs. The technical staff of JIUWU work with experts from the Institute of Membrane Science and Technology of ...

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you