- Home

- Companies

- Water and Wastewater

- Water Filtration and Separation

- MSE Filterpressen GmbH

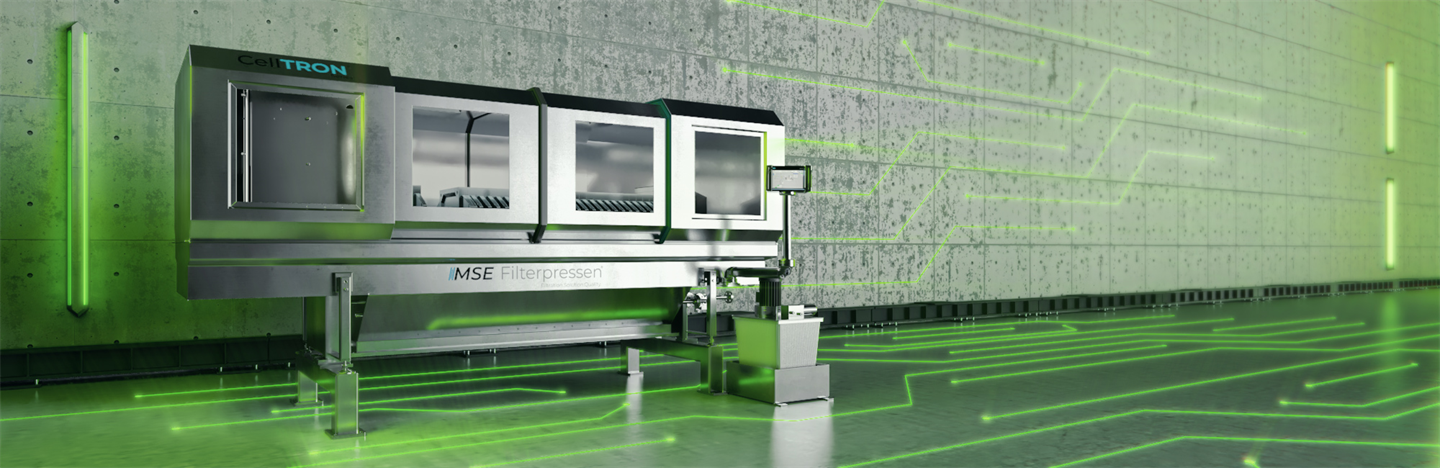

MSE Filterpressen GmbH

MSE Filterpressenc is an owner-managed company which, since its foundation in 1978, has specialised in the development, manufacture and worldwide sale of mechanical filtration plants and dewatering systems for industrial separation processes. MSE stands above all for technologically unique, innovative filter press systems. As experts for high-performance (sludge) dewatering systems, our customers also consult us as a development partner for particularly demanding or complex tasks. With know-how, creativity and optimal technology, our team creates tailor-made solutions that are particularly impressive aesthetically, economically and functionally. In particular, we know how to convince with the newly developed CellTRON Xtreme press line. This 2nd generation filter press is a high-tech filter apparatus that for the first time reliably filters volatile, PharmaFood and hot products as well as substances with toxic and radioactive properties.

Company details

Find locations served, office locations.

- Business Type:

- Manufacturer

- Industry Type:

- Water Filtration and Separation

- Market Focus:

- Globally (various continents)

- Year Founded:

- 1978

- Turnover:

- $1,000,000 US - $10,000,000 US

- Oil, Gas & Refineries

- Paint

- Plastics & Resins

- Printing

- Pulp & Paper

- Soil and Groundwater - Soil and Groundwater Treatment

- Waste and Recycling

- Waste and Recycling

- Waste and Recycling

- Water and Wastewater - Chemical Water Treatment

- Water and Wastewater - Drinking Water

- Water and Wastewater - Water Filtration and Separation

- Water and Wastewater - Water Treatment