Environmental Industry Equipment

-

Showcasebased in NETHERLANDS

H2O can provide electrochlorination systems. Our partners had build up a long reference list of worldwide instralled installations. The range of Electrolyzers are designed for low-maintenance Sodium Hypochlorite (NaOCl) production for on and offshore application.We can also be supplied for non-hazardous and hazardous. The systems can be supplied for installation in both classified and ...

-

ShowcaseManufactured by Finn Corporationbased in USA

Designed with time-tested features, the T330 HydroSeeder offers value, reliability and productivity to meet the needs of large-scale applications. The T330 features the highly efficient FINN proprietary centrifugal slurry pump with a 134hp John Deere diesel engine and an independently controlled pump ...

-

ShowcaseManufactured by Particle Measuring Systems (PMS)based in USA

Portable particle counter for cleanroom certification and cleanroom monitoring. The Lasair® Pro portable particle counter supports a complete contamination control solution including cleanroom certification and clean area monitoring while meeting global requirements for data integrity. Designed for intuitive and reliable aerosol particle counting, this newest addition to the PMS fleet ...

-

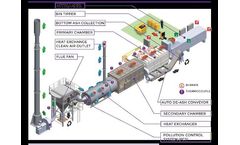

ShowcaseManufactured by Inciner8 Limitedbased in UNITED KINGDOM

Our flagship model is the i8-1000 line. It took over three years to develop and is at the forefront combustion technology, offering impressive burn rates and large batch sizes while still achieving some of the lowest emissions in its class. The i8-1000 can be customised with external cladding and automatic loading/de-ash to provide an effective and sustainable waste disposal solution for many ...

-

ShowcaseManufactured by Labconco Corporationbased in USA

FlaskScrubber Glassware Washers are designed to wash and dry a wide variety of narrow-neck and general purpose labware. Utilizing a brilliant 5” touch screen display featuring CleanWorks OS, users have full control of wash parameters and washer settings. The included lower spindle rack consists of 36 spindles, and 18 glassware holders for narrow-neck glassware such as volumetric and ...

-

ShowcaseManufactured by Cloud Tech Pvt. Ltd.based in INDIA

Cloud Tech wastewater evaporators accelerate this natural process to provide optimal conditions by mechanical enhancement, both by means of the atomisation of water particles into fine molecules through mechanical interference and the propulsion of the water droplets high into the atmosphere to achieve hang time and the direct confluence of dry atmospheric conditions with suspended fine water ...

-

ShowcaseManufactured by Samyang Corporationbased in SOUTH KOREA

Water treatment Specialty, Chemicals & Equipment. TRILITE has launched a new EDI (Electrodeionization) system, an eco-friendly water treatment facility, to provide total solutions to the global water treatment market. In 2022, TRILITE® entered the EDI market by signing an MOU with GEUMHWA WTS Co., Ltd. (formerly, Ecorbit Engineering Co., Ltd.) and is targeting the global premium water ...

-

ShowcaseManufactured by Daimer Industries Inc.based in USA

The KleenJet Pro Plus 200S has a lot to offer when it comes to commercial-grade steam cleaners. If you are looking for an industrial clean that anyone can appreciate, try the KleenJet Pro Plus 200S. This lightweight model gives you an unrivaled clean every time you use it. With over 20 different attachments included, you can tackle almost any cleaning project. Homeowners and business owners alike ...

-

ShowcaseManufactured by Eureka Water Probesbased in USA

The MantaPlus 25 comes standard with temperature, pH, conductivity, and a wipered turbidity sensor, and optional ORP and depth sensors. The M+25 features our refillable pH reference, which requires no expensive consumables. Connect the MantaPlus 25 to any of our field display options for sampling in the field, or add a battery pack for autonomous deployments. Connect to a telemetry station for ...

-

ShowcaseManufactured by VPInstrumentsbased in NETHERLANDS

With the VPFlowScope® In-line flow meter you have the perfect tool for measuring consumption of machines, cost allocation and pressure loss monitoring. The unique design makes this flow meter especially suited for smaller diameters. It is built for small pipes up to ...

-

ShowcaseManufactured by FFP Systems Inc.based in CANADA

Find out more about filter press and slurry dewatering system here at FFP Systems Inc. We are a company in Mississauga, ON that provides an extensive selection of industrial filtering systems. Continue reading through our website to learn more about the filter press feed cycle and its important ...

-

ShowcaseManufactured by ACA Industrybased in DENMARK

The ACA crusher separates the wrapping from the foodstuffs, e.g. chocolate, chips, bread, fruit, etc. for subsequent recycling. The crusher is particularly well suited for crushing of foodstuffs, chocolate, chips, sweets, bread, fruit, etc. After eliminating the wrapping, the foodstuffs can be recycled as animal feed. The ACA crusher is a slow-turning, quiet machine. The size of the output can be ...

-

ShowcaseManufactured by Hermann Sewerin GmbHbased in GERMANY

Gas leak detector with or without pump - for indoor installations and house tests. The EX-TEC SNOOPER 4 is a gas leak detector for detecting the smallest leaks in installation lines and at connection points. The modular device concept allows users to choose either a basic device without a pump (diffusion device) or a device with integrated ...

-

ShowcaseManufactured by Falmouth Scientific, Inc. (FSI)based in USA

The Falmouth Scientific HMS-624 Side Scan Sonar System utilizes advanced technology to provide superior imaging capabilities for deep and shallow water ...

-

ShowcaseManufactured by Phathombased in NEW ZEALAND

Designed for accuracy in reasonably clean water, measuring a TSS range of 0 – 2.5 g/L (SiO2). The S-series are immersion sensors and they use direct attenuated light to measure both TSS and turbidity ...

-

ShowcaseManufactured by For.Tec. Forniture Tecnologiche S.r.l.based in ITALY

Our waste incinerators mod. EXCE OS are discontinuous static ovens, with top loading ...

-

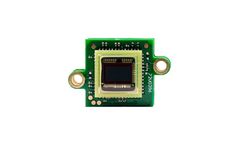

ShowcaseManufactured by Videology Industrial-Grade Camerasbased in USA

15mm x 15mm board ...

-

ShowcaseManufactured by Innovation nilu ASbased in NORWAY

Our new SeSam sequential air sampler is in the final testing stages and is expected to be released in ...

-

ShowcaseManufactured by Skim-pakbased in USA

skim-pak series 600 is designed to remove floating contaminants including oils, foams and particulates from limited access and smaller skimming ...

-

ShowcaseManufactured by Quantek Instruments, Inc.based in USA

The Quantek Model 902D is a benchtop oxygen and CO2 headspace analyzer, primarily used for gas flushed food packages. Achieve accurate oxygen and carbon dioxide measurements in 20-25 seconds. This headspace analyzer contains an internal pump to draw in sample from your package and display O2 and CO2 concentration results in 30 seconds. The expected oxygen sensor life is typically 5 years, unlike ...

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you