Environmental Industry Equipment

-

ShowcaseManufactured by Amafilter®based in NETHERLANDS

The Versis® is a fully automated system with double sided stainless steel pressure filter leaves. It is suitable for most ...

-

ShowcaseManufactured by BioMicrobics, Incbased in USA

The HighStrengthFAST system is an advanced wastewater treatment system that uses Fixed Activated Sludge Treatment (FAST) to break down organic material and nutrients in ...

-

ShowcaseManufactured by OSEI - Oil Spill Eater International, Corpbased in USA

Oil Spill Eater II (OSE II) is the world’s most environmentally safe and cost effective bioremediation process for the mitigation of hazardous waste, spills and contamination virtually anywhere of any size, large or ...

-

ShowcaseManufactured by FPZ S.p.A.based in ITALY

The side channel single-impeller and single-stage (MS) blowers represent one of the main FPZ product ranges. A point of reference in many fields of application, the MS blowers are characterized by a compact design that allows a higher installation flexibility compared to other product ...

-

ShowcaseManufactured by Royal Eijkelkampbased in NETHERLANDS

Auger set for heterogeneous soils, standard set for augerings to a depth of 5 m. With unpainted augers for environmental ...

-

ShowcaseManufactured by Shanghai Metash Instruments Co.,Ltd.based in CHINA

2.5 inches LCD screen: Equipped with a 2.5 inches LCD screen to give a clear display of standard curves and groups of ...

-

ShowcaseManufactured by Cooper Environmental / Sailbri Cooper Inc.based in USA

The Xact® 920 system uses reel-to-reel filter tape sampling and nondestructive X-ray fluorescence (XRF) analysis to monitor aqueous samples for user-selected ...

-

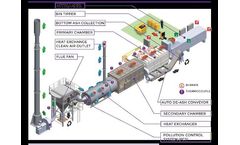

ShowcaseManufactured by Inciner8 Limitedbased in UNITED KINGDOM

Our flagship model is the i8-1000 line. It took over three years to develop and is at the forefront combustion technology, offering impressive burn rates and large batch sizes while still achieving some of the lowest emissions in its class. The i8-1000 can be customised with external cladding and automatic loading/de-ash to provide an effective and sustainable waste disposal solution for many ...

-

ShowcaseManufactured by it4ip S.A.based in BELGIUM

Available in the full pore size range, white and translucent membrane filters having wide and varied applications including air monitoring, water analysis, capture of micro-organism and blood filtration; also available in hydrophilic (PVP treated) or hydrophobic (PVP free) ...

-

ShowcaseManufactured by Avecom NVbased in BELGIUM

Enter a realm of knowledge where we unravel the mysteries of microbial communities. Molecular monitoring is a powerful tool that empowers you to gain valuable insights into your microbial communities. Through this advanced technology, you can precisely identify and quantify specific bacteria within your water samples, providing you with a comprehensive understanding of their composition. The ...

-

ShowcaseManufactured by Water Storage Tanks, Inc.based in USA

Oversized roofs on tanks are a common practice to achieve a more aesthetically appealing roof line with water tanks. Often times this is done to match the profile of masonry or a stone wall covering the exterior of tank or to match the roof line of an existing building or structure. CorGal roofs are regularly used on structures that do not hold water in order to create a visual architectural ...

-

ShowcaseManufactured by Daimer Industries Inc.based in USA

The KleenJet Pro Plus 200S has a lot to offer when it comes to commercial-grade steam cleaners. If you are looking for an industrial clean that anyone can appreciate, try the KleenJet Pro Plus 200S. This lightweight model gives you an unrivaled clean every time you use it. With over 20 different attachments included, you can tackle almost any cleaning project. Homeowners and business owners alike ...

-

Showcasebased in NETHERLANDS

H2O can provide electrochlorination systems. Our partners had build up a long reference list of worldwide instralled installations. The range of Electrolyzers are designed for low-maintenance Sodium Hypochlorite (NaOCl) production for on and offshore application.We can also be supplied for non-hazardous and hazardous. The systems can be supplied for installation in both classified and ...

-

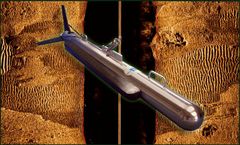

ShowcaseManufactured by Falmouth Scientific, Inc. (FSI)based in USA

The Falmouth Scientific HMS-624 Side Scan Sonar System utilizes advanced technology to provide superior imaging capabilities for deep and shallow water ...

-

ShowcaseManufactured by Gasmet Technologies - a Nederman companybased in FINLAND

Gasmet DX4015 is a portable FTIR gas analyzer for ambient air analysis. The key features of the Gasmet DX4015 include a high sensitivity sample cell for the lowest possible detection limits and a built-in-pump, which means that there is no need to use a separate sampling system. The analyzer can be powered with 12 VDC from for example an external battery, so it can easily be used in field ...

-

ShowcaseManufactured by DILO Armaturen und Anlagen GmbHbased in GERMANY

The handy Mini Series consists of the following individual components which can be assembled as complete ...

-

ShowcaseManufactured by Excalibur Water Systems Inc.based in CANADA

Excalibur Water Systems’ Progressive Flow Water Softening Systems utilize motorized no hard water bypass valves (NHWB) on the outlet of each standard softener control valve, opening or closing water flow based on flow rate demand. The valves allow multiple control valves to always become a multi-tank progressive flow system with one unit online and the remaining unit(s) in stand-by or ...

-

ShowcaseManufactured by Innovation nilu ASbased in NORWAY

Our new SeSam sequential air sampler is in the final testing stages and is expected to be released in ...

-

ShowcaseManufactured by Phathombased in NEW ZEALAND

Designed for accuracy in reasonably clean water, measuring a TSS range of 0 – 2.5 g/L (SiO2). The S-series are immersion sensors and they use direct attenuated light to measure both TSS and turbidity ...

-

ShowcaseManufactured by ForeverPure Corporationbased in USA

ForeverPure Seawater Reverse Osmosis Systems are fully manufactured and tested in the Silicon Valley, California, USA. Only the highest quality components are used in our products. Combining decades of water treatment equipment manufacturing experience and numerous installations around the world, ForeverPure is able to offer top-of-the-line systems with the best value on the market. ...

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you