EnviWaste - Waste to Energy Plant

From Biogas

Waste materials and by-products are accrued in conjunction with every single manufacturing operation, such as enterprises associated with the food and restaurant sector, the fuel industry, the cosmetics sector and the animal husbandry sector. However, the quantity of organic waste produced by the citizenry is also significant for communes – about half a tonne per year per person. In addition to saving you the trouble of disposing of your residual products, our biogas technology also makes it possible for you to convert the waste into useful energy.

-

Most popular related searches

Advantages for Producers

-

Own energy from cogeneration : electricity, steam and heat

Biogas can be used as a source of electricity or to generate heat. After it has been processed into biomethane, it may also be fed into the gas grid. In case of industrial utilisation, the heat that accrues in conjunction with the combustion process taking place in the CHP can be returned to the company in the form of process heat. This is particularly worthwhile for energy-intensive companies with high heat requirements. It makes it possible for such companies to save on heating expenses. - Odour-free, natural fermentation residues for agriculture

If a biogas plant is operated properly, there are no odour nuisances since the produced gas cannot escape from the closed cycle. The fully fermented end product has a noticeably reduced odour after the fermentation process. As high-nutrient fertilisers, these fermentation residues make it unnecessary for farmers to purchase expensive and pollutant mineral fertilisers.

- Filtering and cleaning the digestate residues to process water

Ultra-modern filtration technology makes it possible to further process the digestate. This procedure yields processed service water that can be used for the subsequent industrial process.

- Improved CO2 balance

Thanks to the high energy yield in the EnviWaste plants, the required amount of fossil fuels undergoes a reduction, resulting in a considerable improvement in the CO2 figures of production plants. This gives you an important competitive edge, as more and more consumers and companies are emphasising sustainable production when purchasing products.

What Kinds of Waste are Suitable for Energy Production?

Many organic waste materials are well-suited for use as raw materials in biogas production. In manufacturing, substrates with a high calorific value are often found as waste materials and by-products

- Slaughterhouses

- The food-production industry and the food-processing industry

- Supermarkets, e.g. spoiled food products

- Breweries (malt spent grains)

- Restaurants

- Juice production

- The ethanol industry (mash)

- The biofuel industry, e.g. glycerine

- Animal hunbandry

- Purification plants: Sewage sludge

- The animal feed industry

Our Concept

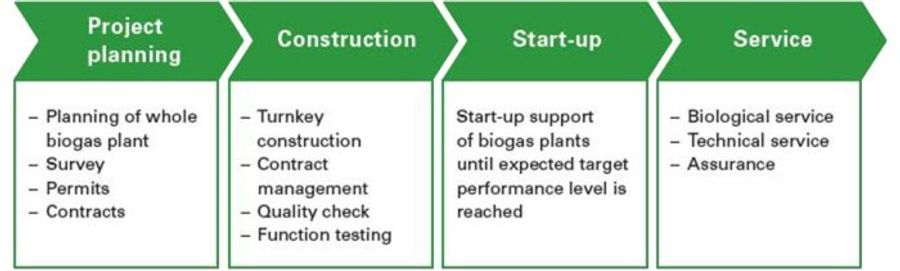

From project planning to service

...we offer you all the steps from one hand. Whether concept design, construction, commissioning or servicing of your EnviWaste-plant - we are on your side. With our offer you can use long-term secured regulatory conditions, guaranteed feed-in tariffs for electricity and the possibilities of the liberalized energy markets. An investment in the future of the renewable energies market pays twice: The environmental impact is reduced, the value chain optimized.

The Process Steps in Detail:

Many different organic waste materials are well-suited for being used as raw materials for the production of biogas. When used in conjunction with the right technology as high-value substrates, food and restaurant waste, green waste, glycerine, slaughterhouse waste and botanical and animal fat can lead to an impressive income. In this regard, the advantage that residual materials have over other input materials which appear to be equally attractive from an energy-related point of view is the fact that these residues do not require any cultivation areas.

Unpacking and cleaning the waste materials

Even packaged waste can be used for biogas production following an automatic separation from its casing. It must also be cleaned, in order to ensure that it is harmless (from the point of view of hygiene) and is free of pathogens. Waste fermentation plants are subject to stringent technical requirements, since plastic packages and the like are non-recyclable and must be removed before the fermentation process is carried out.

Pre-processing and disintegration

In order to ensure that the raw materials are fermented in the best possible manner, they must be broken down to the highest possible degree. Our patented Kreis-Biogas-Dissolver optimally mixes and shreds the input materials to a fine dimension, thereby increasing the biogas output. Various other mixing devices ensure that substrates of varying consistencies can be fed in.

Production of biogas in the digester

In the heated and air-tight digester, the biomass ferments in conjunction with the production of methane, the so-called biogas. The resultant residual product, i.e. the fermented biomass, can be used instead of expensive mineral fertilisers as a low-odour, natural fertiliser in the agricultural or horticultural sector. The filtration of the fermentation residues can also yield process water.

Combustion of the biogas in the CHP

The biogas is incinerated in the combined heat and power plant (CHP), and electricity for which compensation can be obtained is generated. The accruing heat can either be returned to the respective company or fed into the district heating grid. The CHP can be regulated in terms of its utilisation. Consequently, it can correspond to various remuneration regulations and be complemented through other heating concepts.

Production of electricity, heat, bio-natural gas a...

Production of electricity, heat, bio-natural gas and fuel

Biogas can be used in a variety of ways: It can be used to produce electricity and heat for private residences, and it can also be used to supply public buildings or the selfsame manufacturing company. Apart from that, biogas can be channelled into the gas grid after it has been processed into biomethane. It can also be utilized as a fuel that may, for example, be used to facilitate motor vehicle transportation or the actuation of in-house motors.

Our Technology and Experience – Facilitating Successful Investments.

Each waste material requires special treatment, hardly any two industrial operations function in the same manner, all communes have their own characteristics and each country has its own raw materials and laws – the highest degree of flexibility has always been a pre-requisite in our domain. Our goal is to make sure you get as much as you can out of the collaboration, offer the most progressive technology on the market and deliver the smartest marketing concepts for your energy. Consequently, we have consistently managed to occupy a leading position in the global biogas sector.

We are one of the few providers in the market that can serve as a one-stop shop for all the respective stages, and can thus facilitate a successful and friction-free project:

Customer reviews

No reviews were found for EnviWaste - Waste to Energy Plant. Be the first to review!