SONIC START STREAMLINE - Priming System for PISTA Grit Removal System

From Smith & Loveless - Headworks Grit Pumping

The SONIC START® STREAMLINE™ is now available for the PISTA® and in two models: outdoor or indoor. The clean and simplified SONIC START® STREAMLINE™ Prime Sensing System relocates the solenoid valve and frees 50% of the original fitting connection points for an improved priming system. Our innovative and streamlined design delivers superior product performance, quick, easy inspections and virtually no maintenance for years of hassle-free heavy-duty service. Coupled with a premium-efficient pump, the SONIC START® STREAMLINE™make sense for you and the environment—saving you labor hours and costs, and reducing the carbon footprint with fewer maintenance trips.

-

Most popular related searches

Outdoor Model

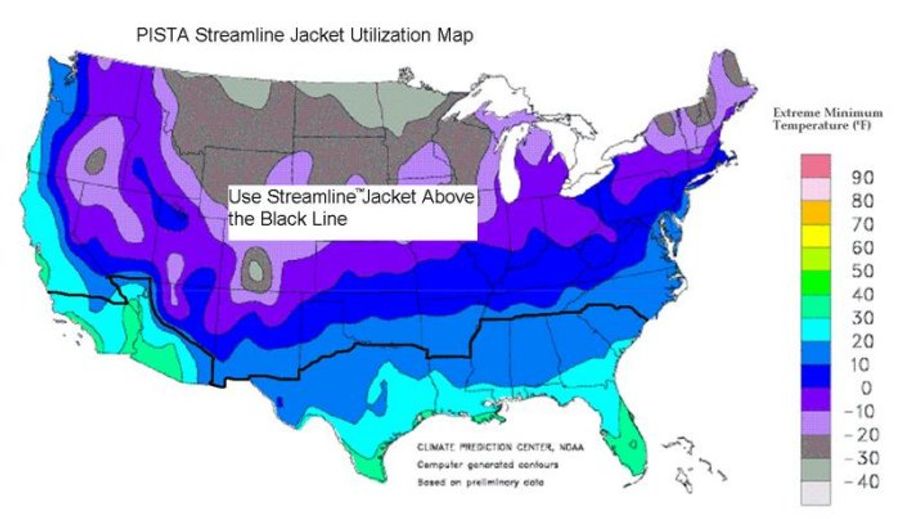

The outdoor model features the SONIC START® Probe, SONIC START® STREAMLINE™ Dome Assembly, and the STREAMLINE™ Jacket (for most locations). The STREAMLINE™ Jacket is both insulated and heated to minimize cold weather issues down to -30F (-34.4444 C) with the probe and dome assembly. It was also especially designed for easy removal. Please reference the map for outdoor locations needing the STREAMLINE™ Jacket (see below).

Explosion Proof

SONIC START® STREAMLINE™ is also available with an explosion-proof option to meet all Class I, Division I, group D requirements. The explosion-proof option includes an explosion-proof SONIC START® Probe and explosion-proof SONIC START® STREAMLINE™ Solenoid Valve to meet all Class I, Division I, Group D requirements.

Features and Benefits

- 50 percent fewer fitting connections

- Takes grit pump pressure off of vacuum tubing and tubing fittings

- Solenoid mounted on top of vacuum dome for improved priming

- Minimizes H2O and debris from reaching the vacuum tubing

- Two models: outdoor and indoor

Customer reviews

No reviews were found for SONIC START STREAMLINE - Priming System for PISTA Grit Removal System. Be the first to review!