Shredder Light Fraction (SLF) / Automobile Shredder Residue (ASR) Recycling Services

From Recycling Areas

Dismantled ELVs (End of Life Vehicles) are sold to shredder operators and are reduced to fist-size pieces by large rotating hammer mills. The Shredder Light Fraction (SLF) is removed from the stream by suction, the intensity of which determines the amount and composition of the SLF. SLF consists essentially of plastics/rubber (~60%), Glass/sand i.e. mineral substances (~15%), Textiles/leather/wood (~10%), Paint dust/rust (~10%) and Residual metals (~5%). Other names for SLF are ASR (Automobile Shredder Residue) and Auto fluff or just fluff. For further processing of the SLF material originating from ELV (End of Life Vehicle), Eldan is able to offer various standard recycling plants. If required, the standard plants are can be customized to suit specific customer requirements.

Input and Output

Dismantled ELVs (End of Life Vehicles) are sold to shredder operators and are reduced to fist-size pieces by large rotating hammer mills. The shredder light fraction (SLF) is removed from the stream by suction, the intensity of which determines the amount and composition of the SLF.

SLF consists essentially of:

- Plastics/rubber (~60%)

- Glass/sand i.e. mineral substances (~15%)

- Textiles/leather/wood (~10%)

- Paint dust/rust (~10%)

- Residual metals (~5%)

- Ferrous metals

- Metals, cables and wires

- Fluff/organic fraction

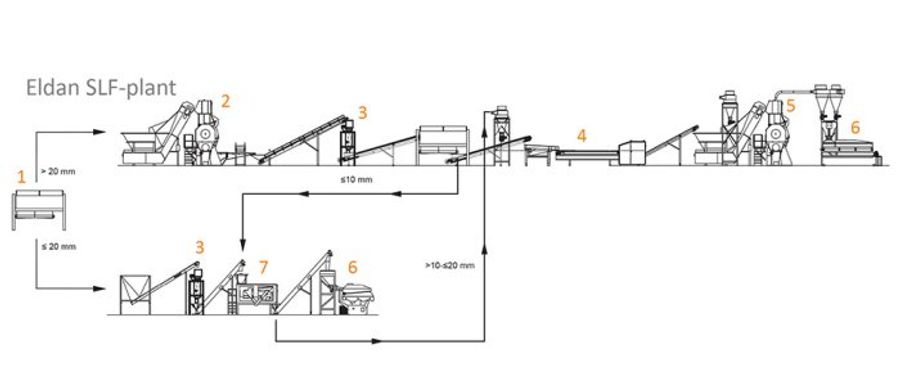

Example of standard set-up: 1. Screener, 2. Heavy ...

Example of standard set-up: 1. Screener, 2. Heavy Granulator with Drum Pusher, 3. Zig-Zag Separator, 4. Metal Detector, 5. Heavy Granulator, 6. Separation Table, 7. Aspirator UP.

Eldan Recycling offer standard and special systems depending on customer requirements in regards to e.g. input size/content and output size/quality. It is also possible to add on to the standard solutions if customer wished to:

- Increase the capacity: use the Ring Shredder for input of more heavy material fractions – partly to size reduce the input and partly to increase the capacity of the SLF recycling plant. Read more.

- Separation of plastic qualities: Eldan is able to offer a solution for PVC plastic (containing chlorine) and brominated flame retardant plastic from other plastic qualities. Read more.

- Granulate and separate wire/cables: Eldan is able to offer a solution to granulate and separate metals from plastic insulation.

Customer reviews

No reviews were found for Shredder Light Fraction (SLF) / Automobile Shredder Residue (ASR) Recycling Services. Be the first to review!