Environmental Industry Software

-

Showcasebased in POLAND

X-Scale Belt is designed to register excavating and loading of bulk materials in such plants like: aggregate mines, gravel pits, cement works. X-Scale Belt may simultaneously operate numerous scales. The software can be adjusted to any type of ...

-

Showcasebased in USA

In addition to our Visual Hydraulics and Visual Water Designer modeling software packages, Innovative Hydraulics also provides custom hydraulic model development and advanced Computational Fluid Dynamics (CFD) modeling. We have created specialty models for a variety of clients and have used our CFD modeling capabilities to analyze various unique flow ...

-

PremiumManufactured by Trace2o Ltd.based in UNITED KINGDOM

The AquaSafe Management Software package (ASMS) is an essential tool for recording water quality data in the field. Comprising of both a mobile App and computer dashboard, it can be used in conjunction with Wagtech Projects and Trace2o’s wide range of portable water testing kits or existing legacy instruments. For convenience, the ASMS mobile App enables an agent to digitally enter and ...

-

PremiumManufactured by Metrohm AGbased in SWITZERLAND

The control software is a crucial component in modern instrumentation. The most sophisticated piece of equipment may be useless if it is controlled with inappropriate software. This is why Metrohm Autolab has developed a full-fledged and powerful software solution that allows you to tap the full potential of your Autolab potentiostat/galvanostat: NOVA. This software gives you full control of ...

-

PremiumManufactured by Particle Measuring Systems (PMS)based in USA

SamplerSight Pharma Software controls syringe operated samplers and collects data from a LiQuilaz particle sensor. SamplerSight Pharma Software allows operators to manage sampling requirements for batch-based operations and provides a comprehensive view of the batch information with histogram, time plot and tabular data presented in an easy to use format that is easily reported. ...

-

PremiumManufactured by BUCHIbased in SWITZERLAND

Operating a BUCHI FT-NIR spectrometer without advanced expertise is easy thanks to the intuitive NIRWare operator software. The bi-directional LIMS interface allows flexible and secure data exchange with full traceability. The suite, in combination with the NIRAnywhere software, allows centralized administration of multiple BUCHI spectrometers within a global or local company ...

-

PremiumManufactured by Particle Measuring Systems (PMS)based in USA

Facility Net Software provides a comprehensive environmental monitoring solution with real-time and historical data display for all Particle Measuring Systems particle counters, molecular contamination monitors and various third-party ...

-

PremiumManufactured by Apex Instruments, Inc.based in USA

The HgCalc Software uses sample run data and trap analysis. The sample run data from the MercSampler™ XC-6000 is imported into the application, where total mercury mass, hourly and total mercury emissions are calculated. The software insures the specifications in 40CFR, part 75 are met. The software will also verify QA/QC specifications regarding Section 2 breakthrough, relative deviation, ...

-

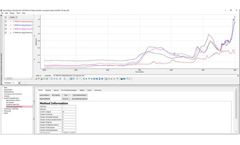

PremiumManufactured by Galaxy Scientific Incbased in USA

Galaxy Scientific’s SpectralSage software suite is a software toolkit for method developers, administrators, and routine users. The suite combines the ease of use needed for routine operation with feature rich functions for the advanced method ...

-

PremiumManufactured by Particle Measuring Systems (PMS)based in USA

Cleanroom environmental monitoring for sampling, reporting, and data retention of particle, microbial and environmental data, meeting 21 CFR Part 11 data integrity requirements. Only Particle Measuring Systems has complete contamination monitoring solutions : Advisory Services, particle counters and microbial air samplers, data management, system installation and validation, and finally ...

-

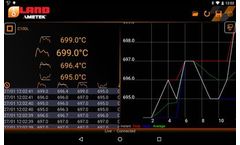

PremiumManufactured by AMETEK Land Instruments International Ltdbased in UNITED KINGDOM

Free software utility enabling Cyclops L portable pyrometer users to view, analyse and save measurement data. Cyclops Logger software allows users to store, view, analyse and record temperature data acquired by our full range of Cyclops L portable ...

-

PremiumManufactured by Solexperts AGbased in SWITZERLAND

The Trical software is used for processing and evaluating measured values and measurement results of the Sliding Micrometer, Sliding Deformeter, Trivec and Borehole Inlinometer. The measured values are usually transferred from the field computer to the office PC or entered manually and then evaluated. The evaluation includes graphical and numerical representations of the displacement profiles in ...

-

PremiumManufactured by Myron L Companybased in USA

The bluDock Accessory Package includes the Guardian software application. Transfer Data Wirelessly with Accuracy, Reliability, & ...

-

PremiumManufactured by Particle Measuring Systems (PMS)based in USA

FacilityPro® Software provides the interface, data management, and reporting for an environmental monitoring system. FacilityPro’s ability to manage viable, nonviable, and environmental data through a common system improves the efficiency of production operations and quality investigations. With the FacilityPro industrial automation architecture, the data processing is performed by the ...

-

PremiumManufactured by Sommer Messtechnikbased in AUSTRIA

Webserver to maintain online measuring networks. Data reception over the internet (TCP/IP), saving records in a databank system and data availability for processing and graphical illustration via web browser. Thanks to the MDS the data are always and for several users online available. ...

-

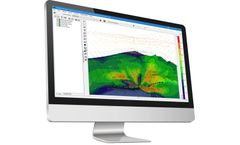

Premiumbased in CANADA

CALPUFF View provides a complete graphical solution for the CALPUFF modeling system: CALPUFF, CALMET, CALPOST, and their related pre- and post-processors. All three modeling systems are supported by the interface: USEPA Approved Version 5.8, Version 6, Version 7. CALPUFF View includes powerful and independent QA tools, stunning report-ready results, and a wide range of visualization ...

-

PremiumManufactured by KISTERSbased in GERMANY

HyComm is used to configure and download data from HyQuest Solutions IoTa LTE-M, IoTa LoRa and iLevel-GW data loggers. HyComm is free to download and ...

-

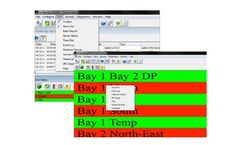

PremiumManufactured by AMETEK Land Instruments International Ltdbased in UNITED KINGDOM

SPOTPro, an advanced software utility, provides a single control point to configure, store and view data for up to 40 SPOT infrared pyrometers. Giving a complete overview of all the SPOT thermometers connected to your network, SPOTPro allows you to independently configure data logging for each thermometer, by setting automatic triggers for data storage. SPOTPro allows users to compare live and ...

-

PremiumManufactured by Oizom Instruments Pvt. Ltd.based in INDIA

Oizom is committed to making environmental data more apprehensible by offering immediate alerts for timely decisions. Data-driven suggestive actions are provided to the authorities to mitigate any significant future risk, such as an industrial accident or natural/man-made hazard. This objective is accomplished by incorporating threshold limits for each parameter, beyond which the authorities are ...

-

PremiumManufactured by Mobiltex Data Ltdbased in CANADA

LTE Swap facilitates the upgrade process from 2G or 3G cellular technology Mobiltex RMU2 and RMU3 units to corresponding pre-purchased LTE units. It helps transfer all settings and configuration data which allows for a quick and simple swap process. If needed, it will also update the firmware of the unit it is connecting to before completing the swap process to ensure that the most up to date ...

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you