Sludge Drying (Sewage Sludge) Equipment

-

Manufactured by Eflo International Ltd.based in UNITED KINGDOM

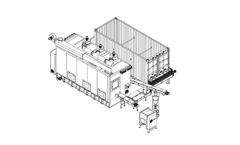

The EfloSludgeDry is a packaged and containerised sludge dewatering system complete with all the necessary polymer preparation and dosing system needed prior to the dewatering process. The EfloSludgeDry is mostly used for dewatering digested sewage sludge from small to medium size treatment plants with a typical feed sludge of 1% ...

-

Manufactured by MAK Waterbased in AUSTRALIA

The WendeWolf system includes a tiller & turner machine that processes dewatered sewage sludge cake into a dry granulated product. The WendeWolf machine is installed inside an enclosed greenhouse building or drying hall. The greenhouse serves to prevent rain from re-wetting the sludge, and capture solar radiation to evaporate ...

-

Manufactured by SolarTiger GmbHbased in AUSTRIA

With our SolarTiger - AO procedure unpleasant odours which may occur during storage and drying of dewatered sewage sludge can be avoided. In the process, there is an indirect intervention in the balance of enzymes of the microorganisms which are responsible for the digestion process. This is how the formation of malodorous digestion ...

-

Manufactured by SolarTiger GmbHbased in AUSTRIA

SolarTiger stands for innovative and sustainable drying technology, using natural resources. Under the brand name of SolarTiger all components for the construction of a solar drying plant are launched. Thereby the components offered components range from automation of the solar drying, via dewatering of sludge, right through to ...

-

Manufactured by Thermo-System Industrie- & Trocknungstechnik GmbHbased in GERMANY

The StorageDryer™ combines the fully automatic drying and the storage of sludge in one plant. The fully automatic, year-round loading and the necessity to unload the plant only once a year offer maximum operating reliability for minimum work effort. The StorageDryer™ - a clever solution for plants between 1 000 and 30 000 ...

-

Manufactured by Thermo-System Industrie- & Trocknungstechnik GmbHbased in GERMANY

The SludgeManager combines the good points of the proven Electric Mole™, such as robustness, ease of maintenance and stainless-steel construction, with the advantages of fully automated operation. It has been developed jointly by Thermo-System, the ACAT company and the University of Hohenheim. In contrast to the drying ...

-

Manufactured by SolarTiger GmbHbased in AUSTRIA

SchlammFIT stands for sludge filtration with integrated drying. This system was developed especially for WWTPs up to 15.000 PE. Thereby, liquid sewage sludge with 98 – 95% water content is dehydrated in the SchlammFIT gutter by utilization of the natural gravitation to a dry matter content of 12 – 15%. The SchlammFIT ...

-

Manufactured by Grace Filter Manufacturing (U.K) Ltdbased in CHINA

Waste Water Treatment Sludge Dewatering Equipment Belt Press Filter Cloth. Vacuum Belt Filter Press Cloth Double Layer PP Filtration Belt With Metal Clipper. Filter Belt is applied in Belt Type Filter Machine , main industry is wasterwater treatment , sludge dewatering , paper plant . Our filter belt is perfectly installed in horizaontal ...

-

Manufactured by Amcon Inc.based in JAPAN

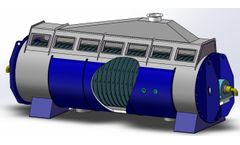

This is a drum-type dryer that performs drying by a steam-heated drum. This machine can convert waste activated sludge and chemical sludge into dried sludge with a water content of 10 to 40%, reducing the amount of waste sludge. * The K series is a product of KANKYO SETSUBI Co., ...

-

Manufactured by Amcon Inc.based in JAPAN

This system can convert waste activated sludge and chemical sludge into dried sludge with a water content of 10 to 40%, reducing the amount of the waste sludge. High thermal efficiency is achieved with the direct contact of the the dewatered cake to the heat source. The unique double layered drum structure ensures a sufficient ...

-

Manufactured by SEEN Technologie sp. z o.o.based in POLAND

Solar drying of sludge SOLARTIGER: work based on the greenhouse effect, reduction of sludge, sludge drying up to 75 - 90% DS, low electricity consumption, simple operation, low maintenance ...

-

Manufactured by SEEN Technologie sp. z o.o.based in POLAND

Thermal drying of sludge: Reduction of sludge, sludge drying up to 75 - 90% DS, low heatconsumption, continuous dried ...

-

Manufactured by Thermo-System Industrie- & Trocknungstechnik GmbHbased in GERMANY

Drying with theElectric Moleis a batch or semi-continuous process that always ensures optimal drying performance, independent of sludge characteristics, weather conditions and energy ...

-

Manufactured by BIOETP Environmental Protection Engineering Co., Ltd.based in CHINA

QY-SG-80 disc dryer system for sludge dryer treatment, EU advanced technology, double disc dryer,larger drying area, special mechanical design for protecting all welding seams, in-direct steam heated, continuously drying ...

-

Manufactured by BIOETP Environmental Protection Engineering Co., Ltd.based in CHINA

QY-SG-50 sludge dryer system for sludge dryer treatment, EU advanced technology, double disc dryer,larger drying area, special mechanical design for protecting all welding seams, in-direct steam heated, continuously drying ...

-

Manufactured by Henan ZJN Environmental Sci-Tech Co., Ltdbased in CHINA

There are many sludge left after waste waster disposal. The moisture content may be not high, but they are very pasty, very hard to dry. Our drying equipment use large volume low temperature technology to dry. Combining with rotary harrow and specially leading and raising boards, we can dry sewage ...

-

Manufactured by Huber SEbased in GERMANY

The basic principle of the HUBER SRT system is drying of sewage sludge in a glasshouse using the incident solar radiation. What makes the HUBER SRT system special is the HUBER Sludge Turner SOLSTICE®, which performs spreading and granulation of the sludge in the greenhouse and aeration, turning and mixing of the ...

-

Manufactured by Henan ZJN Environmental Sci-Tech Co., Ltdbased in CHINA

Municipal sludge relates to people living environment and health. It is necessary dry them. However, municipal sludge is high humidity and strong viscosity and easily to bond again, traditional drying machine can’t dry it completely. Our drying equipment is triple stage and multi-loop ...

-

Manufactured by Jumbo Group Smart Dry Gmbhbased in GERMANY

Safe disposal of sewage sludge from wastewater treatment is an urgent problem that is associated with increasing environmental requirements and costs that continue to rise. Sewage sludge drying is becoming increasingly important and requires technically efficient and economical systems. With our SpeedRotation STR dryer series, we ...

-

Manufactured by BIOETP Environmental Protection Engineering Co., Ltd.based in CHINA

QY-SG series sludge dryer, used EU advanced technology, double disc dryer, special mechanical design for protecting all welding seams, in-direct steam heated, continuously drying ...

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you