Ultrasound Solutions for Bearing Lubrication Monitoring - Monitoring and Testing

For 4000 years we have been lubricating our machinery and rotating assets to increase their efficiency, reliability and lifespan. Proper bearing lubrication minimizes the surface contact of machinery, reducing undesired friction, excessive heat, metal-on-metal contact and wear and tear.

Lubrication not only protects ball and roller-element bearings from themselves by reducing friction but also from corrosion and the elements. Grease is the lubrication of choice within the industry, as it is easy to apply and it provides the bearing housing with a protective seal from the elements.

For a procedure proven reliable for the past 4 millennia, it is surprising to hear so many premature bearing failures are lubrication-related. In short, improper lube selection, amount, intervals as well as lubricant contamination and degradation are to blame.

Mistake No.1 Calendar based lubrication

There are many parameters influencing equipment’s need for grease (load, environment, temperature, etc.)

Therefore, it is crucial that all these factors are considered, not just a “timing” component based on a theoretical calculation.

Over and undergreasing

Using too much or too little lubricant leads to wear or premature breakage of the bearing. In the first case because of elevated temperature and friction, the second through metal-to-metal contact causing the bearing to seize after some time.

Using listening mode only

Simply listening, without taking measurements and recordings, is certainly too subjective, and cannot be recommended. Only comparative analysis of the status of the bearing, before and after greasing, is truly objective.

Ultrasound is the best condition monitoring technology for detecting friction, impacting and turbulence. The main purpose of lubrication is to reduce undesired friction and metal-on-metal contact. Ultrasound can detect increased levels of friction as a result of too much, or too little grease.

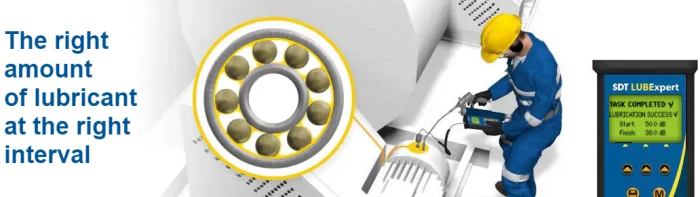

Taking measurements with your ultrasound device is the best, and easiest way to determine when your bearings require grease. Observing changes in dB’s is the first telltale sign that your bearing requires some maintenance So, the first step is to establish a baseline.

The only way to know when a bearing is in need of lubrication is monitoring its condition with an ultrasound device. Over time, bearing grease degrades and friction levels increase which is detectable with ultrasound. For this reason, and in order to prolong its life and prevent failure, the bearing needs grease replenishment.

An Ultrasound Device allows users to carefully monitor a bearing during a lubrication task. Both audio and visual representations of the bearings decibel level are displayed to provide greasing guidance. As grease is added to the bearing the decibel levels will decrease. Once dB levels begin to climb slightly, you know you have reached the optimal level of grease.