- Home

- Companies

- Earth Shield Environmental Co., Ltd.

- Articles

- 2.0mm HDPE Geomembrane for Gold Mining ...

2.0mm HDPE Geomembrane for Gold Mining Project in Ghana

Ghana, formerly known as the “Gold Coast,” has a centuries-long history of gold mining. Today, gold remains a mainstay of Ghana’s economy.

However, mining has also caused increasingly serious environmental problems. Mining operations discharge large amounts of silt and toxic substances (especially mercury and cyanide) into rivers, destroying many river ecosystems and rendering the water murky and undrinkable. Major river systems such as the Pula River have been severely affected. Furthermore, the excavation of massive mine pits without backfilling renders land unusable for agriculture and creates safety hazards. Mining activities have also encroached upon and destroyed vast amounts of protected forests.

HDPE geomembranes play a crucial environmental role in gold mining in Ghana. Their application directly addresses the most severe challenges posed by illegal gold mining in Ghana—water and soil pollution. Preventing leakage and controlling pollution are the most important values of geomembranes.

Heap Leaching Pond Liner: In large-scale industrial gold mines, sodium cyanide solution is commonly used to spray crushed ore heaps to dissolve gold. The site for this process—the heap leaching pond—must be absolutely impermeable. As an impermeable liner, it ensures that the precious solution containing cyanide and heavy metals does not seep into the ground, contaminating the soil and groundwater. This is crucial for protecting Ghana’s precious water resources.

Tailings Dam Liner: Waste remaining after gold extraction from ore is typically washed into sludge and stored in tailings ponds. These tailings contain residual chemicals, heavy metals, and other hazardous substances. Laying HDPE geomembranes at the bottom and slopes of the tailings pond creates an “artificial basin,” completely isolating toxic and hazardous tailings wastewater from the natural environment. This is a key engineering measure to prevent lasting environmental disasters caused by mining.

Wastewater Treatment/Sedimentation Tank Liner: Mining processes generate large amounts of wastewater that needs to be collected and treated. Geomembranes are used to construct these treatment ponds, ensuring that wastewater does not leak before treatment.

The client is the operations manager of a gold mining company in Ghana. Recently, the client has been under immense pressure. Officials from the Mining Commission and the Environmental Protection Agency have been visiting increasingly frequently, pointing to the soil around the client’s tailings dam and demanding permeability test reports. New regulations are very strict; if tailings wastewater pollutes groundwater, the client will face hefty fines or even license revocation. Nearby villagers have been protesting, saying the client’s activities are polluting their water sources. Villagers frequently block roads, disrupting the client’s transportation. A permanent solution must be found.

A Ghanaian client searched on Google for “geomenbrane for gold mining tailings,” “HDPE liner supplier Ghana,” and “mining environmental protection solution.” The client needed a one-stop geotextile expert with a proven track record of success serving the mining industry, not just a typical building materials supplier. The client found us, and we provided successful case studies from mining plants in African countries such as South Africa (copper mines) and Tanzania (gold mines). We sent the client geomembrane samples free of charge, and after testing, they fully met the client’s quality requirements. The client then selected our 2.0mm HDPE geomembrane.

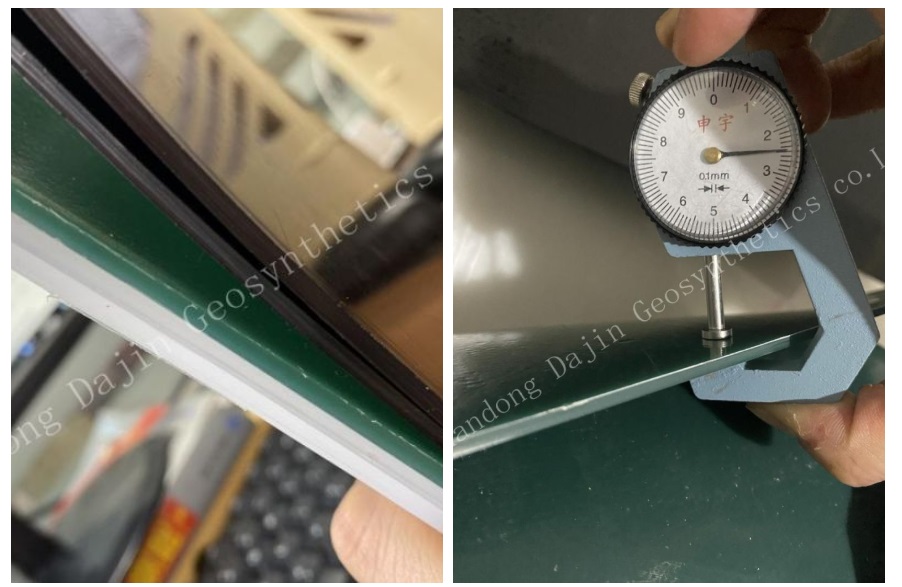

Thickness: 2.0mm

Quality Standard: ASTM GRI GM 13

Geomembrane Size: 8x100m

Quantity for the Project: 500,000 square meters

Customer Selection of HDPE Geomembrane Thickness

In the mining industry, once a geomembrane is laid, it is almost impossible to replace. If leakage occurs, it can be catastrophic. Therefore, the selection of HDPE geomembrane thickness follows a “conservative principle,” meaning choosing a thickness with a sufficient safety margin within the budget of the mining project.

Uneven Foundation Settlement: Tailings dam foundations in mining areas are typically compacted soil, which may experience uneven settlement. A 2.00mm thick HDPE geomembrane provides higher tensile and tear strength, better withstanding stress from foundation deformation without cracking.

Sharp Rocks and Construction Damage: Although the foundation is leveled and compacted, sharp gravel may still remain. A thicker geomembrane offers greater puncture resistance.

Long-Term Creep Performance: Geomembranes undergo creep (slow deformation) under long-term loads. A thicker geomembrane provides better long-term dimensional stability, resisting continuous stretching caused by the weight of overlying tailings and wastewater.

Intense UV Radiation: Ghana is located in the tropics with extremely strong UV radiation. HDPE geomembranes age under prolonged UV exposure. A 2.00mm thickness means the geomembrane better resists surface degradation caused by UV radiation, ensuring its design life (e.g., over 50 years) remains unaffected. Chemical Corrosion Risk: Gold mine tailings may contain cyanide, heavy metals, and acidic or alkaline substances. Thicker geomembranes provide longer, chemically resistant infiltration paths. Even with slight surface chemical erosion, the thicker membrane maintains the overall integrity of its impermeability.

High-Risk Consequences: Tailings dams are known as “mining time bombs,” with failures resulting in environmental disasters, astronomical fines, ruined company reputations, and even criminal liability. For such a high-risk facility, clients will not skimp on the most crucial impermeable layer.

Economies of Scale: For a large tailings dam project, the cost of geomembrane materials is not a significant percentage of the total investment. Choosing 2.00mm instead of 1.5mm results in a limited increase in total cost, but the resulting improvement in safety margin is substantial. This is a very economical way to hedge against risk.

International Design Standards: International geomembrane standards like GRI GM13 typically recommend minimum thicknesses based on the application scenario. For large-scale mining tailings dams, which are considered primary seepage prevention projects, 1.5mm is generally recognized as the minimum threshold, while 2.0mm is increasingly becoming industry best practice and a mandatory requirement for many consulting engineers.

Why not 1.5mm? While 1.5mm might theoretically be sufficient, it lacks the safety margin to handle unforeseen construction damage, foundation settlement, and long-term creep. Clients will always have a nagging question: “How long will it last?” Choosing 2.00mm makes the project appear more secure and reliable.

Diminishing returns on investment: Increasing thickness significantly increases material costs, transportation costs, and welding difficulty. For most working conditions, 2.00mm already provides sufficient safety; further increases in thickness offer limited performance improvements and are uneconomical.

Construction convenience: Excessively thick geomembranes reduce flexibility, making laying and welding more difficult and demanding on the construction team. This could potentially introduce new risks due to welding quality issues. Furthermore, to reduce the workload of geomembrane welding, EarthShield produces 8m*100m geomembranes for its Ghanaian clients, minimizing welding time and reducing the possibility of leaks.

As a leading geomembrane supplier from China, we have deep expertise in the mining seepage control sector, providing safe, reliable, and environmentally friendly solutions for mines worldwide. We possess extensive industry experience and a profound understanding of the stringent requirements of core facilities, from tailings ponds to heap leaching ponds. Our products are fully certified by international standards such as ISO and CE, guaranteeing quality. We offer both flexibility and deep collaboration, fully supporting OEM and ODM services to ensure your specific needs are perfectly met. We firmly believe in the superior performance of our products and are happy to provide free geomembrane samples, letting the quality speak for itself. Contact us for 24/7 online technical support!