- Home

- Companies

- USA Borescopes

- Articles

- How Borescopes Support Maintenance the ...

How Borescopes Support Maintenance the Decision-Making Process

Modern aircraft engines generate enormous amount of internal stress—from high temperatures to rotational forces and corrosive airflows. As components wear, accumulate residue, or exhibit early signs of fatigue or overheating, professional maintenance teams rely on precise diagnostic information to determine the appropriate corrective action. According to aviation maintenance guidelines and remote visual inspection (RVI) research, high-quality videoscope and borescope data has become one of the most reliable forms of nondestructive evidence for evaluating internal engine health and reliability. Similarly, industry studies highlight the value of documented visual data in reducing unnecessary part replacements and improving long-term operational reliability. Thus, saving time and money.

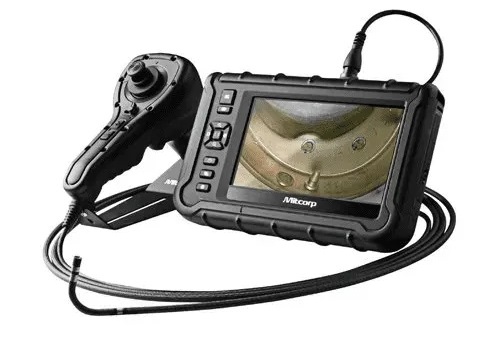

Videoscopes provide technicians with direct, high-resolution visuals of internal engine structures and components without time consuming disassembly. Beyond real-time visibility, the ability to record, save, share and review inspection details is what makes videoscope data especially powerful. Engineers and Inspectors can assess the condition of components, compare visuals with previous inspections, and confidently decide whether a part needs cleaning, repair, continued monitoring, or full replacement.

Long story short, aviation vehicles whether fixed wing or rotor wing require regular or intermittent inspections. And when it comes to commercial aviation, airplanes don’t make money on the ground. So, if maintenance professionals can save time and money without compromising the safety and health of the aircraft, it’s a win-win situation.

Aircraft engines (whether fixed wing or rotor wing) demand strict maintenance control because internal issues can develop rapidly. Aviation maintenance technicians need more than intuition or a gut feeling—they need objective, objective evidence to make sound decisions. Borescope data serves as a documented visual record that helps maintenance professionals:

- Identify early-stage cracks or fatigue

- Identify discoloration and thermal distress

- Appraise carbon buildup or deposits

- Evaluate blade and vane health

- Confirm lubrication pathways

- Verify seal and gasket condition

- Discover clearance or alignment issues

- Confirm and identify suspected FOD (foreign object debris)

These insights help prevent misinterpretation and provide a reliable foundation for sound aviation maintenance decisions.

Not all component wear necessitates part replacement. Videoscope data helps engineers distinguish between:

- Removable residue (carbon deposits, oil varnish)

- Surface-level discoloration

- Minor erosion

- Serious structural damage

For example, mild carbon buildup on turbine blades may be cleaned during scheduled maintenance, whereas cracking or heat distortion may require component replacement.

Most videoscopes include image and video recording features. Maintenance teams can compare footage from:

- Previous borescope inspections

- Post-flight evaluations

- Post-overhaul checks

- Mid-cycle maintenance reviews

- For smaller engines, the ‘Pre-Buy’ inspection data

Trend analysis allows technicians to detect worsening conditions, such as crack propagation or thermal barrier coating degradation, overheating, and adjust maintenance intervals appropriately.

Visual evidence strengthens the validity of:

- Stated Warranty claims

- Component life-limit evaluations

- Compliance documentation

- Return-to-service approvals

- Out of service declination

- Customer Data Requirements

Videoscope recordings offer proof—rather than assumption—when confirming engine health. Different types of mathematical proofs include Direct Proof, Proof by Contradiction, Proof by Contrapositive, Proof by Induction, and Proof by Cases, which are fundamental logical structures for establishing truth and sound decision making, alongside other methods like existence proofs, exhaustion, and computer-assisted proofs, all using definitions to build a logical argument.

When addressing unexpected vibration, over-temperature warnings, or abnormal engine performance, videoscope data helps quickly isolate:

- Blocked cooling passages

- Damaged blades (propeller or turbine)

- Oil or fuel contamination

- Loose fasteners

- Seal leakage

- Seal Degradation

With visual confirmation, technicians avoid unnecessary teardown and repair the true root cause.

To support accurate engineering and aviation maintenance decisions, aviation videoscopes must offer:

High-Resolution Sensors

Clear images allow evaluation of microscopic defects and subtle surface changes. In the past HD image quality was a premium offering for borescope providers. At present, HD image quality borescopes are a standard feature.

Proper lighting reduces glare on reflective turbine surfaces and reveals hidden damage. Whether the LED lighting is offered at the tip with LED anodes or it is delivered by a leached fiberscope bundle the expectation for aviation maintenance is that the LED lighting be adjustable. The adjustability allows the aviation maintenance professional to enhance or diminish the lighting depending not only of the depth of the borescope inspection but the reflectiveness of the inspection area.

4-way articulation allows technicians to inspect blade platforms, roots, and trailing edges with precision. Articulation refers to the ability of the aviation engine inspector to steer or adjust the tip of the probe to view a complete area of the inspection target. Smaller diameter borescopes will typically offer a shorter bending section. A borescope bending section refers to the area that is required to complete a full turn (or rotation) of the borescope tip. A small diameter borescope will offer a shorter bending section than a larger borescope probe.

Documentation of the performed inspection enables cross-team review and long-term component health tracking. Taking photos and videos with a borescope is now a standard feature. Most borescopes and videoscopes will store the images on a SD card. Very few borescopes store the data on board. In years past this was an optional feature.

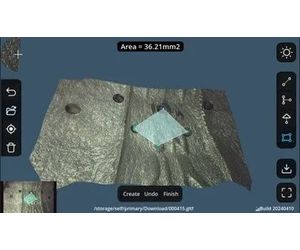

Some systems include reference grids or dimensional analysis features, helping quantify:

- Crack length

- Clearance spacing

- Wear patterns

These measurements support more informed decisions than visual assessment alone. The ‘reference grid’ is not a true measurable offering but as stated, only a reference. Many experienced aviation maintenance professionals state that they can identify a cracked or compromised turbine blade without the assistance of a measuring videoscope. Of course, the decision to ground a plane from flight service is going to require more than a gut feeling.

While other systems will provide quantitative borescope measurement features with either stereo measuring or 3D borescope measuring:

- These systems will provide point to point measuring of cracks

- This measuring borescope will also provide the depth of a crack or pit

- Most all measuring borescope manufactures offer a Measurement Error: 5%

- All commercial borescope inspections require a measuring borescope

Predictive maintenance relies on data—visual, mechanical, and environmental. Videoscope recordings play a significant role in airline and helicopter operator programs by identifying wear before failure occurs.

Visual evidence helps maintenance teams:

- Adjust inspection intervals

- Identify early corrosion or oxidation

- Monitor coating wear rates

- Validate performance after repairs

- Detect anomalies following extreme flight conditions

This data-driven approach reduces the risk of in-service failures and optimizes the lifespan of expensive turbine components.

Here at USA Borescopes, we supply aviation and aerospace quality videoscopes designed specifically for aviation engine and hot-section inspections. Our borescope machines feature:

- High-resolution imaging

- LED illumination

- 4mm or 6mm articulating probes with various working lengths

- Image and video recording

- Rugged designs for MRO environments

They also support aviation professionals with:

- No-cost repair evaluations

- Fast borescope rentals in the continental U.S.

- Overnight shipping when possible

- Repair services for all borescope models with No Charge repair estimates

By providing aviation tools capable of capturing precise visual data, we help maintenance teams make smarter, more reliable decisions.

Browse our wide selection of industrial videoscopes, pipe cameras, rigid borescopes, Explosion proof borescope systems, and fiberscopes through USA Borescopes. We invite you to Explore our complete offerings of high-quality inspection tools designed for aviation professionals. We also offer expert borescope repair services for every make and model with No Charge repair estimates.

Need help choosing the right inspection camera for tricky or a hard-to-see inspection challenge? Call 931-362-3304 for world-class assistance.