Mastering the Submersible Centrifugal Pump: Applications, Benefits, and Buying Tips

The submersible centrifugal pump is designed to be submerged in the fluid being pumped, offering several benefits over traditional above-ground pumps. This pump operates using centrifugal force to move fluid through the system. It has become an essential tool in heavy-duty sectors, including mining, wastewater management, and construction. As industries grow, so does the demand for pumps that can handle abrasive, slurry, and sludge materials.

This blog will explore the key features of submersible centrifugal pumps, including their applications, benefits, and what you need to know when purchasing one for your business.

The submersible centrifugal pump operates based on the principle of centrifugal force, a fundamental physical concept that generates flow and pressure within the system. When the pump is activated, the impeller within the pump rotates rapidly, creating centrifugal force. This force causes the fluid to move outward from the center of the pump, pushing it through the discharge pipe and into the system.

Operating Principle of Centrifugal Force in Submersible Design

The submersible design of these pumps allows the pump to be fully submerged in the fluid, eliminating the need for long suction lines or external piping. This design reduces the risk of airlocks and cavitation, which can negatively impact performance in above-ground pumps. The centrifugal force generated by the rotating impeller efficiently moves large volumes of fluid with high-pressure requirements, making it ideal for a wide variety of industrial applications.

Comparison with Traditional Above-Ground Centrifugal Pumps

In contrast to traditional above-ground centrifugal pumps, the submersible centrifugal pump is placed directly within the fluid. This configuration allows it to operate with a more compact design and more consistent performance, especially in confined or submerged environments. Since the pump is completely sealed and submerged, it minimizes the need for external maintenance, which can be costly and complex.

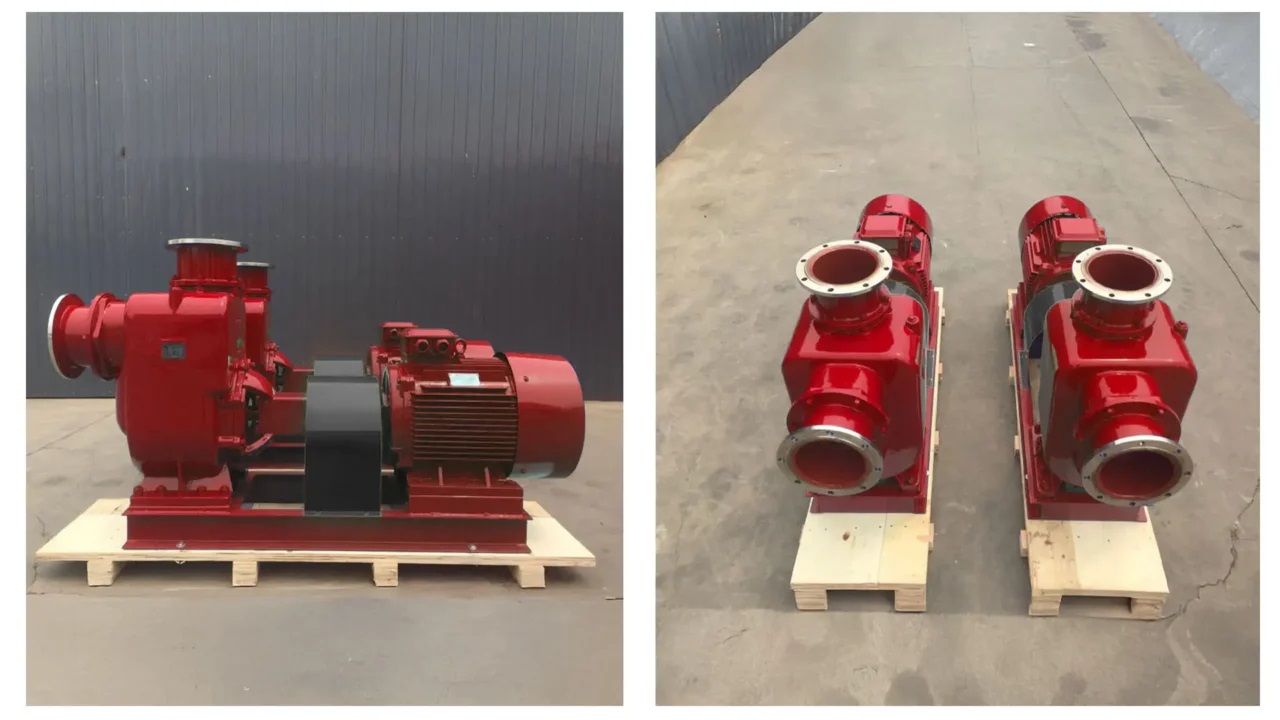

Key Components: Impeller, Motor, Casing, Shaft Seals

The main components of a submersible centrifugal pump include:

- Impeller: The rotating component that imparts kinetic energy to the fluid, driving the centrifugal force.

- Motor: Provides the mechanical energy to rotate the impeller. It is typically housed within the pump casing, allowing it to operate submerged.

- Casing: The outer shell that encases the motor and impeller, designed to prevent leakage and withstand high-pressure conditions.

- Shaft Seals: These seals protect the motor from fluid ingress and prevent leakage, thereby ensuring the pump’s longevity and efficiency.

These components work in harmony to create an efficient and reliable pumping system, making the submersible centrifugal pump the go-to solution in industries that require continuous operation and dependability.

The submersible centrifugal pump has proven indispensable across various industries. Its versatility, durability, and reliability make it ideal for a variety of applications that require handling challenging materials, such as abrasives, sludge, and slurry.

- Mining: Handling Abrasive Material with Centrifugal Slurry Pump Variants

In the mining industry, where fluids can be laden with coarse, abrasive particles, the centrifugal slurry pump is essential for transporting mineral slurries from one part of the operation to another. These slurries are often thick, viscous, and abrasive, which requires a pump capable of handling such demanding conditions. The centrifugal slurry pump utilizes centrifugal force to efficiently pump these mixtures, reducing wear and tear on pump components while improving overall operational efficiency.

- Wastewater: Sludge Management with Centrifugal Sludge Pumps

Wastewater treatment facilities require robust pumping solutions for the removal and transportation of sludge, a byproduct of the treatment process. The centrifugal sludge pump is specifically designed to handle thick, high-density materials, such as sewage sludge and industrial wastewater. These pumps are engineered with anti-clogging designs to ensure reliable operation even in the presence of solid particles. The centrifugal force helps move these dense fluids with ease, allowing wastewater plants to maintain smooth operations.

- Construction: Dewatering and Silt Removal

Construction sites frequently encounter challenges related to water accumulation, particularly in areas near rivers or lakes. Submersible centrifugal pumps are used for dewatering, ensuring that excess water is removed to create a dry environment for construction activities. These pumps are also effective in silt removal, a crucial task in many construction projects where the presence of silt can hinder progress and lead to equipment malfunctions. The pump’s ability to handle suspended solids, such as sand and silt, makes it a reliable solution for construction sites.

- Oil & Gas: Hydrocarbon Sludge Pumping

In the oil and gas sector, submersible centrifugal pumps are utilized to handle hydrocarbon sludge, a highly viscous mixture of oil, water, and solids. These pumps are designed to withstand corrosive environments and handle the abrasive nature of hydrocarbon sludge. The centrifugal sludge pump variant is often used in this industry, offering a durable and reliable solution for managing and transporting these materials from one point to another in drilling, production, and refining processes.

When selecting a submersible centrifugal pump, several key features should be considered to ensure the pump meets the demands of your application.

- Solids-Handling Capacity and Anti-Clogging Design

The centrifugal slurry pump and centrifugal sludge pump are both designed to handle solids-laden fluids. These pumps are often used in applications where clogging can be a significant issue. The anti-clogging design helps ensure that the pump continues to operate without frequent maintenance or blockage, increasing uptime and reducing the need for repairs.

- Durability Under Continuous Operation

Many industries require submersible centrifugal pumps to run 24/7. Whether it’s a construction site requiring continuous dewatering or a mining operation where slurry must be constantly moved, the durability of the pump under continuous operation is crucial. Pumps used in these settings are typically built with heavy-duty materials that can withstand wear, pressure, and harsh fluid conditions.

- Corrosion and Abrasion Resistance

The fluids that centrifugal sludge pumps and centrifugal slurry pumps handle are often abrasive or corrosive. Pumps that are resistant to these conditions are essential for ensuring long-term performance. Pumps designed with stainless steel or other corrosion-resistant materials offer enhanced protection against the damaging effects of harsh chemicals and abrasive solids.

- Energy Efficiency and Flow Rate Control

In industries where pumps operate continuously, energy efficiency is crucial. Submersible centrifugal pumps are designed with energy-efficient motors that reduce power consumption without sacrificing performance. Adjustable flow rate controls also help optimize the pumping system for varying operational needs, ensuring that the pump operates at peak efficiency.

Understanding the differences between a centrifugal slurry pump and a centrifugal sludge pump is essential when selecting the right equipment for your needs. While both types of pumps fall under the category of submersible centrifugal pumps, they are designed for different applications.

What Is a Centrifugal Slurry Pump vs. a Centrifugal Sludge Pump?

A centrifugal slurry pump is designed for transporting slurries—mixtures of water and solid particles—typically found in mining, dredging, and construction applications. These pumps are built to handle large particles and abrasive materials.

On the other hand, a centrifugal sludge pump is designed for thicker, more viscous liquids, such as sewage sludge or industrial wastewater. These pumps are optimized for handling high-density, solid-laden liquids and are often used in wastewater treatment plants or in industrial applications that generate significant amounts of sludge.

Material Viscosity, Particle Size, and Wear Considerations

The key difference between the two pumps lies in their design features, which are based on the type of material they are designed to pump. Centrifugal slurry pumps are designed to handle larger particles and are built with more robust materials to reduce wear. In contrast, centrifugal sludge pumps focus on pumping thicker fluids with higher viscosity, requiring specialized materials to prevent clogging and ensure consistent operation.

Before purchasing a submersible centrifugal pump, consider several key factors to ensure the pump meets your operational requirements.

Flow Rate, Head, and NPSH

The flow rate, head, and net positive suction head (NPSH) are critical performance parameters for any pumping system. These factors determine the amount of fluid the pump can handle, the pressure it can generate, and its ability to withstand suction conditions. Understanding these parameters will help you select the right centrifugal slurry pump or centrifugal sludge pump based on your system’s specific needs.

Fluid Characteristics and Pump Material

The type of fluid being pumped plays a significant role in determining the appropriate pump material. Centrifugal slurry pumps may require pumps made from harder materials, such as cast iron or stainless steel, to handle abrasive particles. Centrifugal sludge pumps, on the other hand, may require materials that can withstand the corrosive nature of wastewater or chemical sludges.

Submersion Depth and Motor Protection (IP Ratings)

The submersion depth and motor protection (measured by IP ratings) are crucial to ensure the pump operates safely and efficiently underwater. IP ratings indicate how well the motor is protected from water and debris, ensuring that it can withstand the harsh environments typical in submersible pump applications.

Maintenance and Servicing Requirements

Selecting a submersible centrifugal pump that is easy to maintain and service is important for reducing downtime. Ensure that the pump you choose has readily available spare parts and that it can be easily repaired in the field.

Even the best submersible centrifugal pumps can face challenges during operation. Here are some common issues and troubleshooting tips:

Clogging and Impeller Damage

Clogging and impeller damage are common issues when handling abrasive materials. Regular inspection and maintenance of the impeller can help prevent these problems. Also, choosing a pump with an anti-clogging design can reduce the likelihood of impeller damage.

Motor Overheating

Motor overheating can occur if the pump is not properly maintained or if it is operated beyond its rated capacity. Ensuring that the pump is correctly sized for the application and operating within the specified parameters will help prevent overheating issues.

Seal Failure and Preventive Maintenance

Seal failure can lead to leakage and potential damage to the motor. Regular inspection and timely replacement of seals are essential to maintaining the pump’s reliability and efficiency.

DAE Pumps offers a wide range of submersible centrifugal pumps designed for heavy-duty industrial applications. Whether you need a centrifugal slurry pump for mining or a centrifugal sludge pump for wastewater treatment, we have a solution that fits your needs.

Our pumps are designed for durability, efficiency, and performance, and we provide engineering support and custom solutions tailored to your specific needs. DAE Pumps is a trusted provider, recognized for its rugged build quality, prompt delivery options, and exceptional customer service.

The submersible centrifugal pump has proven its value across multiple industries by providing reliable, efficient solutions for transporting abrasive, viscous, and sludge-filled fluids. Whether used in mining, wastewater treatment, or construction, these pumps are engineered to withstand the most demanding conditions.

DAE Pumps offers a comprehensive selection of centrifugal slurry pumps, centrifugal sludge pumps, and submersible centrifugal pumps designed for various industrial applications. Contact our experts today to find the perfect pump for your operations and download our comprehensive guide to submersible centrifugal pumps.