- Home

- Companies

- Lighthouse Worldwide Solutions (LWS)

- Articles

- Vaporized Hydrogen Peroxide and Apex ...

Vaporized Hydrogen Peroxide and Apex Instruments

Vaporized Hydrogen Peroxide (VHP) is recognized as a highly effective sterilizing agent, widely utilized for disinfecting surfaces and equipment in cleanroom environments. This method is particularly prevalent in the medical equipment and pharmaceutical industries, where maintaining an exceptionally sterile environment is paramount to ensuring product safety and regulatory compliance. Despite its effectiveness, VHP is a potent chemical that can gradually cause the deterioration and breakdown of sensitive equipment and materials exposed to it on a regular basis.

Given the critical nature of these industries, it is often necessary to perform sterilization procedures while the cleanroom remains fully operational. This means that equipment and tools within the cleanroom are frequently

subjected to VHP exposure, sometimes for extended periods. As a result, it is essential that any instruments or devices used in these settings are specifically engineered to resist the potentially damaging effects of VHP.

Lighthouse`s Apex particle counters are an excellent example of such robust equipment. These devices have been subjected to thorough and rigorous testing to assess their durability and performance when exposed to VHP. The results of these tests have shown that the Apex particle counters experience no significant or abnormal wear, even after repeated exposure to vaporized hydrogen peroxide. This impressive resilience ensures that they remain reliable and effective for monitoring cleanroom conditions, even in environments where VHP sterilization is routinely employed.

What is VHP?

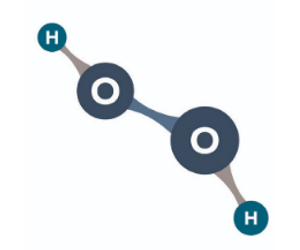

Vapor Hydrogen Peroxide VHP (H202) is registered by the U.S. Environmental Protection Agency as a sterilant. The EPA defines a sterilant as "a substance that destroys or eliminates all forms of microbial life in the inanimate environment, including all forms of vegetative bacteria, bacterial spores, fungi, fungal spores, and viruses". As a sterilant, VHP is one of the chemicals approved for decontamination of anthrax spores from contaminated buildings, such as during the 2001 anthrax attacks in the U.S. It has also been shown to effectively remove exotic animal viruses, such as avian influenza and Newcastle disease from equipment and surfaces. VHP is used in Hospitals and in the Pharmaceutical Manufacturing Industry.

Why is VHP Used in Cleanrooms

Cleanrooms that manufacture drugs, biological products, and medical devices undergo vigorous sterilization processes. The use of hydrogen peroxide to disinfect surfaces is perhaps the most critical disinfection procedure. Product safety and quality, as well as human health, depends on the quality and thoroughness of a surface disinfection wipe-down. Some manufacturing processes run 24/7 to keep up with the demands for pharmaceutical products and avoid product shortages. Thus, offline shutdowns are short and most of the sterilization is done in-situ. It is, therefore, important to select equipment that it is compatible and VHP tolerant.

What are the Impacts on Partile Counters

VHP is produced by the vaporization of liquid hydrogen peroxide at 120°C to create a mixture of VHP and water vapor. As a `dry` process, the concentration of VHP is maintained below a given condensation point. This is dependent on the area temperature. For room decontamination, VHP is generally maintained well below the saturation concentration at 0.1-1.5mg/L at 25°C. For medical device sterilization, higher concentrations can be used at higher process temperature, generally up to 60°C.

When the concentration of VHP increases above the saturation point for a given temperature, hydrogen peroxide will preferentially condense out. This forms concentrated peroxide on a surface, as peroxide has a lower vapor pressure than water. In this situation, although the condensate may be antimicrobial, the process may become variable and damage surfaces.

This is the scenario that poses a danger to all process equipment in a cleanroom, including but not limited to particle counters.