A & A Magnetics Inc. products

A-A-Magnetics - Crossbelt and Inline Overhead Suspended Separators

Overhead Suspended Separators are a practical and efficient way to seperate ferrous metal from fast-moving materials on conveyors. These units protect machinery, and their strength provides constant product purification. Overhead Separators are suited for applications with wet, dry, fine or coarse materials and are available in standard In-line and Crossbelt models. These direct-drive, self-cleaning units are designed to handle your tougher scrap metal seperation requirements and assure product purity. Both models are available in a wide variety of sizes to fit your needs.

A-A-Magnetics - Magnetic Cross Belt Separators

The A&A CBS Crossbelt Separators are ideal for recycling operations and are widely used in the sorting of co-mingled items (steel cans, bottle caps, etc.). This economical cross belt separator provides powerful, yet efficient separation of ferrous metal from aluminum, glass, plastics and wood. These magnetic separators are available in seven standard self-cleaning models to fit your requirements and increase productivity. All are equipped with permanent magnets and a 3/4 horsepower motor. Belts are made of heavy duty rubber with cleats spaced according to the application. Maximum belt speed is 155 FPM.

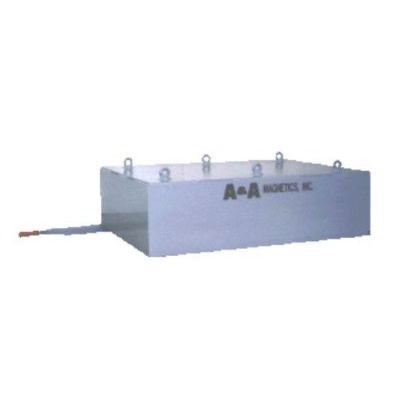

A-A-Magnetics - Stationary Suspended Separators

A&A Stationary Suspended Separators are powerful, non-electric units designed to provide efficient separation of ferrous metal from free-flowing granular or clumping materials. These manually cleaned magnetic separators provide maximum protection from equipment damage and related hazards caused by tramp iron. Our magnetic overhead separators are available in five standard strength models with a variety of sizes to fit your requirements. Support frames are optional.

A-A-Magnetics - Magnetic Drum Separators

A&A Magnetic Drum Separators are ideal for processing operations where granular or pulverized materials (such as chemicals, tobacco, food, grains, plastics, and rubber) are conveyed in closed chutes. Material is fed in through the top where a revolving cylinder carries it over a stationary magnet. The magnetic field attracts and holds tramp iron beyond the discharge of the cleaned product flow. Tramp iron is then released into a separate discharge as it leaves the magnetic field. The self-cleaning unit comes equipped with a standard direct drive motor. Available in single or double drum configurations depending on your application.

A-A-Magnetics - Plate Magnets

A&A Plate Magnets are used to remove scrap metal from items such as grains, glass, chemicals, plastics, minerals and foodstuffs. These units are primarily used in ducts and chutes or suspended over conveyor belts. Plate magnets prevent damage to equipment and product contamination by effectively removing tramp iron from free-flowing materials and materials under pressure. They provide permanent magnetic strength and are easily installed to fit most granulators in use today. Five standard models are available with widths starting at 6 inches.

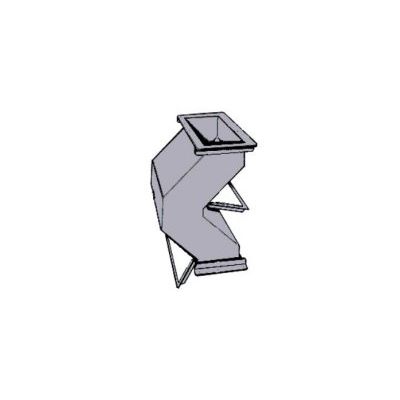

A-A-Magnetics - Magnetic Hump Separators

A&A Magnetic Hump Assemblies were designed to direct product and contaminant flow into the magnetic fields of plate separators. The deflected flow pattern helps to break up clumps of material, providing maximum protection against entrapped contaminants. The hump separator is used where heavy, loose flowing materials such as fibers, chemicals, clay products, grain, feed and sand are conveyed in vertical, down gravity flow chutes. Whether installed vertically or horizontally, falling material strikes directly against the first magnetic plate and the subsequent change of direction permits the second magnet to remove any remaining tramp iron. The two Magnetic plates are hinged to swing out for fast, easy cleaning. Optional features include spouting adapters, all stainless steel construction and portholes for observation.

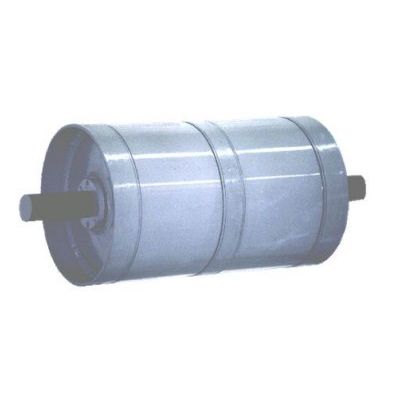

A-A-Magnetics - Magnetic Pulleys

A&A Magnetic Pulleys are widely used in the recycling industry to separate ferrous from non-ferrous items. As head pulleys on belt conveyors, they provide maximum continuous protection against tramp iron contamination in the processing of materials such as chemicals, plastics, grains, food products, ceramics and coal. Our self cleaning pulleys are equally effective in the separation of both large and fine metal particles from non-ferrous material. These easily installed units provide permanent magnetic strength and require no maintenance.

A-A-Magnetics - Super Power Pulleys

A&A Super Power Pulleys provide maximum protection against tramp iron contamination. These pulleys are widely used as head pulleys on belt conveyors in industries such as mining, paper, textiles, feed and foodstuff, drugs, chemicals and rubber. Our self-cleaning pulleys are equally effective in the separation of both large and fine metal particles from non-ferrous materials.

A-A-Magnetics - Pass Through Separators

A&A Pass Through Separators consist of two opposing plate magnets mounted on a common housing. As material flows through the housing, the magnetic material is held by the plates as the cleaned product is allowed to exit. These separators are available in manual or self cleaning models and in any size to fit your specific application.

A-A-Magnetics - Magnetic Drawer Grates

A&A Magnetic Drawer Grates remove tramp metal from dry, free-flowing materials such as sugar, spices, plastics and chemicals. These grates are located directly over machinery openings and below material hoppers so that all material must pass before entering the process machinery, insuring constant magnetic protection. These in-line magnetic filters are ruggedly constructed to support the weight of material hoppers, dryers and mixers. The magnetic housings match existing hopper mounting facilities for easy installation. Available in Single and Double Bank, Ceramic 8 or RARE EARTH magnets.