Accusharp Cutting Tools Pvt. Ltd products

Drills

Accusharp - Solid Carbide Step Drill

ACCUSHARP offers a complete range of high performance, general purpose, finishing, roughing, high-speed, micro and material-specific S/C Step drill for high productivity and extended tool life.

Accusharp - Solid Carbide Tch Double Margin Drills

Chip pockets are broad, allowing for superior chip management and evacuation. The new HiPIMS Coating, which is designed specifically for cutting drill, ensures consistent and long tool life in a wide range of work materials and applications. For tiny machines, it provides solid drilling with no wobbling and a better hole finish with a double margin.

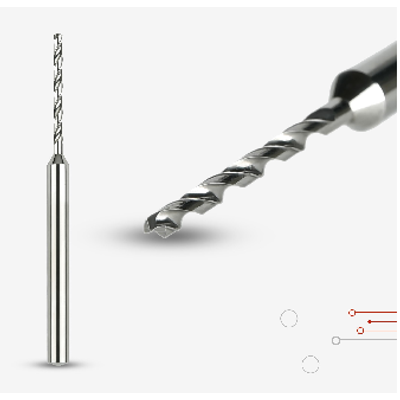

Accusharp - Micro Drill

Accusharp micro twist drill bits are excellent for producing smooth, precision holes and drilling through all hard metals. ACCUSHARP offers a family of small diameter carbide micro drill for precision drilling in medical, aerospace and the automotive industry. The Exclusive Line of high precision carbide drills are available in solid and coolant fed carbide designs from 0.30 mm to 3.0 mm diameter.

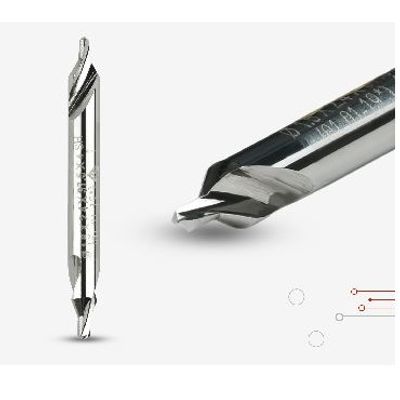

Accusharp - Carbide Center Drill

ACCUSHARP make center drills are used in Automotive, Aerospace & other manufacturing industry. Center Drills are used for providing centering holes on shafts faces, so to hold them between centers for other CNC job work. Carbide Center Drill bits are Good for large batch production.Carbide Center Drills comes with varied chamfer angles of 45° / 60° or as per customer request or drawings.

Endmills

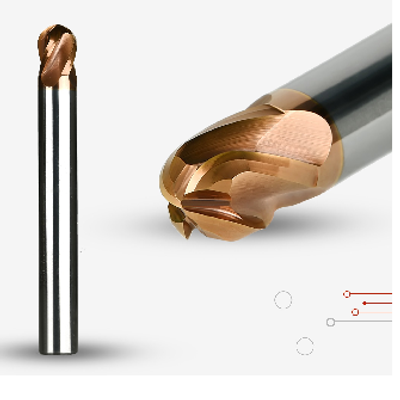

Accusharp - 4 Flute Ball Nose Endmill

Use for contouring and radius parts and surfaces. Designed to cut a variety of materials, including nickel base alloys, stainless steel, difficult alloys, abrasive and non-ferrous metals. Premium submicron grain carbide is used.Die and mould industries, automobile industries, aerospace industries, and other industries are among the well-supplied. ACCUSHARP’s four flute ball end mill design allows for a lot of chip evacuation, making it ideal for contouring deep pockets in moulds and dies.

Accusharp - Thread Mill Tools

ACCUSHARP Thread mills are used to make threads on machining centers with helical interpolation capabilities. The advantages of thread milling over tapping are dependent on the customer’s requirements. Thread milling is ideal for short-run operations, especially in pricey products where thread finish is crucial. Thread milling can be used to machine difficult-to-machine materials such inconel, hard steels, and titanium as well as short-run tasks needing taper pipe threads. The solid carbide HiPIMS coated thread mills from ACCUSHARP are helical fluted to cut easily like an end mill and the AlTin multi-layer coating provides substantially longer tool life and allows milling in harder materials.

Reamers

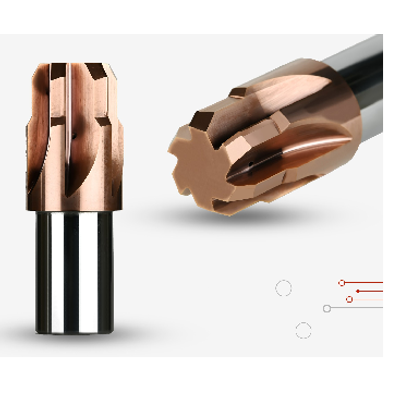

Accusharp - Solid Carbide Reamer

Acuusharp reamer is a type of rotary cutting tool used for surface finishing operation along with controlled tolerated hole. A typical reamer geometry consists of parallel/ straight or helical cutting edges along the length of a cylindrical body. All cutting edges are ground at a slight angle and with a slight undercut below the cutting edge. This ensures a long life for the reamer and a superior finish to the hole. having HSN2 and Alcorna coating for good surface finsih and less wear of the tool using high parameters with the best design.

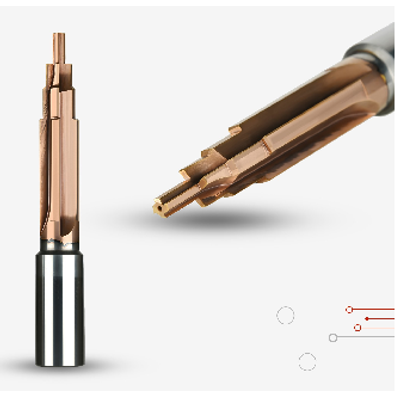

Accusharp - Combination Reamer

A reamer with two or more enhanced cutting diameters is known as a combination reamer. The advantages of utilizing a combination reamer is that it reduces the number of operations while holding depths, internal diameters and maintaining aligned concentricity more accurately. All types of stainless steel, hardened steel and mixed alloyed steel are suitable. HiPIMS coating has a long tool life and is less wear resistant than other coatings.

Accusharp - Solid Carbide Injector Bore Reamer

Customers can receive on-the-job training from ACCUSHARP on the right selection, use and application of reaming tools. Acusharp provides the greatest answer for this in the vehicle industry. Reamers are frequently made by combining many stages, which substantially reduces cycle time while also maintaining the best geometrical accuracy. All high precision bores in steel and cast iron with tolerances starting from IT7 to IT9. Fulfil the reaming of the fuel injector bore. Tool with a Coated Solid Carbide Coating. 345 RPM, 227 mm/min High Pressure Through Coolant.

Brazed Carbide Tool

Accusharp - Model T Slot - Brazed Carbide Cutter

ACCUSHARP has a wide variety of Solid Carbide TIP T-Slot Cutter options, including high-performance, general purpose, finishing, roughing, high-speed, micro and material specific options. T-Slot Cutter with Solid Carbide Tip for High Productivity and Long Tool Life. T-grooving and milling are both possible with the T-Slot / Carbide cutter. Both side faces are bladed, unlike key sheaths, making it suited for processing T grooves. To support high precision groove cutting, the tip is formed of solid carbide.