ACI products

Environment - Size Separator

ACI - Disc Screen

The Disc screen is working to take the fine fractions out from the feeding stream to the air shifter. Various working width and length are supplied depending on the capacity. With the inverter installed, the variable rotor rotation speeds give the flexibility in sorting sizes. Large diameter rotor prevents the long materials from clogging the shafts. ACI sorting discs have double shapes triangular for main sorting part and hexagonal for clogging prevention.

Environment - Multiple Separator

ACI - Air Ballistic Separator

Air Ballistic Separator is a hybrid machine that combines Air Shifter and Ballistic Separator. Thanks to the great combination, the machine can separate many kinds of wastes into various shapes in one machine; Heavy Material / 3D Material / 2D Material / Fine Fraction. In addition, the cartridge filter purifies dusts efficiently, and the air recirculation device minimizes the dust emission.

Environment - Baler

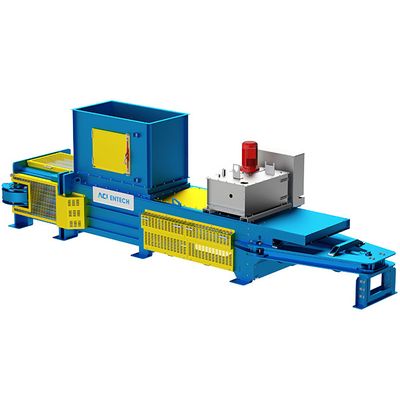

ACI - Semi-Automatic Baler

Semi-Automatic Baler is to compress various materials into square bale automatically. The bale bindings are done manually by the operator with the vertical and/or cross tying method. Thanks to the guide-tube, the operator can finish the tying work very quickly. The Level Sensors integrated in the feeding hopper help to control the pressing cycle efficiently.

Environment - Other Products

ACI - Bag Splitter

The bag splitter is to split open the bags of MSW (Municipal Solid Waste) and supply them to the sorting machines continuously and evenly. The collected waste bags will be fed to the bunker of the bag splitter. Retractable splitting knives mounted in the rotor take the bags of the wastes to the ripping combs and open the bags to feed the wastes to the sorting machines. The bag splitters are used at MRF (Material Recovery Facility) and MBT (Mechanical Biological Treatment) Facility.

ACI - Preshredder Stationary/Mobile

The Preshredder is equipped with the electrical motor, the hydraulic pump and the hydraulic motor, shreds the wastes with knives attached on the rotors and the cutting table, and feeds the shred materials to the output conveyor. The cutting shafts rotate in both directions and have the long material rolling prevention function. The cutting knives are double edged for wear-resistant and impact-resistant properties. The Preshredder has 6 shredding programs to meet the best shredding function depending on the feeing materials.