Advanced Surface Technologies, Inc. (AST) products

AST - Electroless Nickel Plating

Advanced Surface Technologies specializes in high quality Electroless Nickel Plating. Electroless Nickel is a high quality engineering coating fo:

AST - Electroless Nickel Plating with PTFE

Electroless Nickel Plating with PTFE or PEN-TUF®/EN is an Electroless Nickel Composite coating containing particles of PTFE evenly dispersed in a Nickel Phosphorus matrix. During the plating process the PTFE particles are suspended in the Electroless Nickel bath creating a uniform co-deposit.

AST - Boron Nitride Electroless Nickel

Boron Nitride Electroless Nickel (BNEN) plating service provides a composite deposition of Electroless Nickel and Boron Nitride particles. This plating is one of our advanced composite plating operations ideal for parts that require both hardness as well as lubricity. Deposit Benefits include exceptionally low coefficient of friction, superior release and excellent wear resistance. BNEN can be coated to thicknesses ranging from .00005-.002 inches. Unlike EN-PTFE, EN Boron Nitride deposits can be heat treated to attain maximum hardness for very severe wear applications. Advanced Surface Technologies can deposit the Electroless Nickel with Boron Nitride on Aluminum, Copper, Brass, Magnesium, Stainless Steel and Steel. Deposit characteristics include:

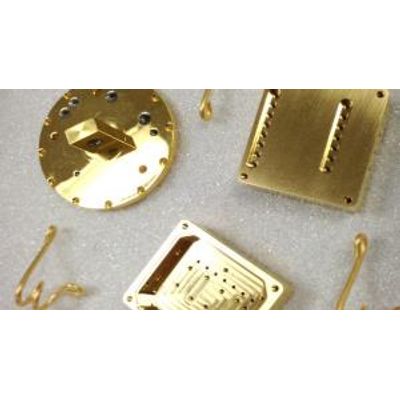

AST - Gold Plating

Advanced Surface Technologies offers Type III pure Gold Plating and Type I and II Nickel hardened Gold Plating on a wide variety of substrates including Aluminum, Brass, Copper, Steel, Stainless Steel and Magnesium.

AST - Electrolytic Nickel Plating

Advanced Surface Technologies has both Bright and Sulfamate Electrolytic nickel plating for a diverse range of engineering and cosmetic applications. Sulfamate Nickel plating provides a Nickel deposit for corrosion protection and is a functional highly ductile, low stress deposit used in applications where there is flexing, crimping, soldering, brazing and bonding.

AST - Silver Plating

Silver plating is a cost effective solution for applications that require low contact resistance, high thermal conductivity and chemical stability. AST offers matte, semi bright and bright silver platings ranging from 99.0% to 99.9% purity that conform to QQ-S-365 and ASTM B700 specifications. A RoHS compliant post plating chromate treatment is also available.

AST - Tin Plating

AST provides a Bright Acid Tin plating compliant to MIL-T-10727, Type I and ASTM B 545. Our tin plating processes facilitate soldering and improve anti-galling properties in steel, brass, copper, plus numerous other substrates, which otherwise have poor solderability. Tin plating exhibits excellent corrosion resistance and conductivity in a variety of electrical as well as electronic components.

AST - Magnesium Plating

AST offers magnesium plating services for your magnesium components. Coatings that we deposit on magnesium parts include Chromate Conversion (RoHS), Electroless Nickel, Electroless Nickel/PTFE, Electroless Nickel Boron Nitride, Gold, and Silver. All plating operations are performed to ASTM and Mil standard Specifications.

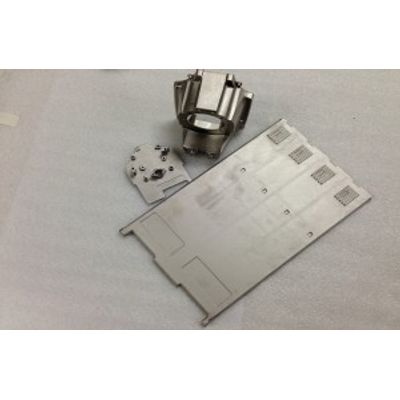

AST - Passivation Stainless Steel Parts

Passivation is a chemical treatment applied to stainless steel parts to provide resistance to oxidation, rusting and mild chemical attack. The Passivation process removes free iron (ferric material) from the surface of the parts that can be created during finishing operations such as milling, buffing, lapping, cutting, etc. These contaminants create potential sites for corrosion that result in premature deterioration of the component. The acids used for Passivation dissolve much of the alloyed iron on an atomic level right at the surface leaving a chromium and nickel-rich surface. It then creates the formation of a thin oxide film that protects the stainless steel from corrosion.

AST - Chromate Conversion Coating

Chromate Conversion Coating (also commonly referred to as Chemical Film, Chem Film, Alodine or Iridite) converts the surface properties of the substrate (typically aluminum or magnesium) as compared to plating which applies a coating onto the surface of the substrate. Chromate provides excellent corrosion resistance, is conductive and results in no measurable buildup (0.00001”- 0.00003”) on the parts.