AECOM products

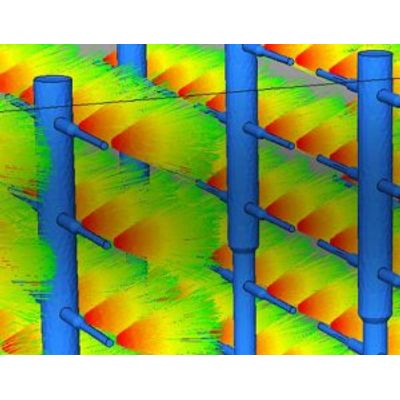

Model Co-Flo - Scrubber

The Co-Flo™ Scrubber is innovative acid gas control technology ideal for retrofitting small and industrial boilers where cost and space limitation may preclude other options. While upgrading existing flue gas desulfurization (FGD) units at coal-fired power plants, AECOM Process Technologies developed and implemented at commercial scale a novel FGD system based on co-current gas and liquid flow that can achieve an SO2 removal efficiency of 98% or greater. For small boiler and industrial applications, a Co-Flo Scrubber may cost less than half of a conventional FGD system.

Concrete Dewatering Tank

AECOM Process Technologies offers the Concrete Dewatering Tank as a lower-cost solution to ELG and CCR compliance. The Concrete Dewatering Tank (CDT) is designed as a series of integrated settling basins that effectively remove solids, oil and grease from ash transport water and low-volume wastewater as it flows through the system. With incorporated pH and temperature control, the treated water can either be discharged or reused. A combination of natural and chemically-enhanced settling permits the removal of solids using an excavator, which are allowed to drain on a concrete pad that slopes towards the CDT until they are dry enough for transport to a landfill or for beneficial use. Compared to other technologies, the CDT minimizes storage volume and rotating and redundant equipment. With solids excavation remaining largely manual, a lower capital investment is required.

HBS Injection

HBS InjectionTM is a technology for mercury oxidation and control that reduces or eliminates reliance on costly powdered activated carbon (PAC) for MATS compliance. A patented process offered exclusively by AECOM Process Technologies, HBS InjectionTM involves the injection of a halogen-based solution (HBS) into flue gas, which reacts in-situ to form halogen species that effectively oxidize elemental mercury to a water-soluble species. The process has been demonstrated at full-scale to reduce elemental mercury levels in the flue gas by more than 75%, with a corresponding reduction in stack mercury emissions for plants operating wet (or semi-dry) FGD processes.

In-duct Wastewater Evaporation

In-duct Wastewater Evaporation is a simple, low-cost way of achieving zero liquid discharge from a wet FGD process. Atomized wastewater is evaporated using flue gas upstream of the particulate control device. The dissolved solids form particulate captured with the fly ash for disposal or beneficial use. AECOM Process Technologies has successfully deployed technology involving the injection of atomized salt solutions for more than a decade. We have the experience, tools, and technology to do this successfully and reliably. With In-duct Wastewater Evaporation, the purge stream from the wet FGD process is introduced directly into the flue gas using the existing ductwork. The water is evaporated and the suspended and dissolved solids that were present form particulate. By introducing the wastewater upstream of the particulate control device, the additional particulate is collected with the fly ash prior to its disposal or beneficial use.

Low Temperature Oxidation (LoTOx™)

The LoTOxTM process uses ozone to oxidize insoluble NOx to higher oxides that are then captured in a wet or semi-dry FGD process. The low temperature process allows stable and constant NOx control regardless of load or concentration. AECOM Process Technologies is the licensee of Linde LLC`s patented LoTOx process for power industry applications. LoTOx involves the injection of ozone into low-temperature flue gas (optimally ≤300°F) to oxidize NO and NO2 to N2O5, which is highly soluble. The flue gas moisture and the liquid in the downstream wet or semi-dry FGD process easily and quickly converts N2O5 to nitric acid (HNO3). The conversion of the N2O5 into the aqueous phase is rapid and irreversible, allowing for near-complete removal of NOx.