- Home

- Companies

- Aetna Plastics

- Products

Aetna Plastics products

Industrial Plastics - Corrosion Resistant Plastics

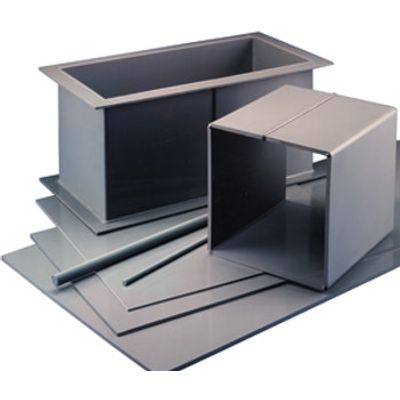

Aetna Corzan - Model CPVC - Corrosion Resistant Plastics

Although it is derived from PVC and thus shares some of that material’s characteristics, CPVC is a distinct polymer. It is a high-temperature-grade chlorinated polyvinyl chloride that is resistant to corrosion, heat, and chemicals. CPVC can be easily machined with standard woodworking tools and can be fiberglass-backed, hot-air welded with rod, cemented (solvent bonded), riveted, and threaded. This material is useful for a wide range of applications, from chemical processing to metal finishing.

Industrial Plastics - Engineering Plastics

Aetna - Model ABS - Acrylonitrile Butadiene Styrene

ABS (Acrylonitrile Butadiene Styrene) is a low-cost engineering plastic that bridges the gap between standard plastics and high-performance engineering thermoplastics. Its versatility comes from its three monomers: acrylonitrile enhances heat stability and chemical resistance, butadiene provides impact strength and toughness, and styrene allows for good formability and rigidity. ABS is easy to machine and fabricate and is widely used for machining preproduction prototypes because it has excellent dimensional stability and is easy to paint and glue. Natural (beige) ABS is FDA-compliant for use in food-processing applications.

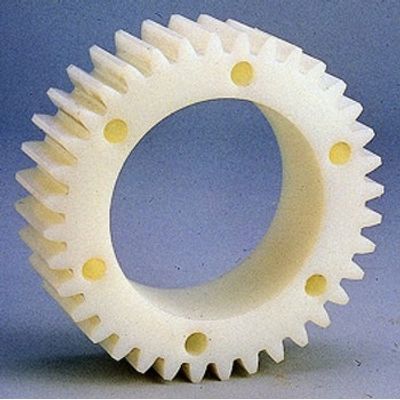

Aetna - Model Acetal Delrin - Semi-Crystalline Material

Acetal provides high strength and stiffness while offering enhanced dimensional stability and ease of machining. A semi-crystalline material, Acetal also has a low coefficient of friction and good wear properties—especially in wet environments. Because it absorbs little moisture, Acetal demonstrates excellent stability for close-tolerance machined parts. In high-moisture or submerged applications, Acetal bearings can outperform nylon 4 to 1. This material is resistant to a wide range of chemicals, including many solvents. Acetal is available in a broad range of grades with properties addressing specific needs.

Industrial Plastics - Fluoropolymer Materials

Halar - Model E-CTFE - Ethylene Chlorotrifluoroethylene

E-CTFE (ethylene-chlorotrifluoroethylene), also known as Halar®, is a partially fluorinated semicrystalline polymer offering an array of mechanical properties and thermal and chemical resistance while also being easy to process. Halar® has excellent corrosion and chemical resistance and performs well in many applications at temperatures up to 300° F. It has excellent mechanical properties and extraordinary impact strength at temperatures ranging from -104° F to 302° F. Halar® is extremely low in permeability from liquids, gases and vapors. It is resistant to most corrosive chemicals, except for hot amines and ketones. The surface is very smooth and its purity is high. Halar® weathers well and is highly resistant to radiation. Typical applications include semiconductor process equipment, chemical storage, fluid handling, solid and lined pipe, tanks and tank linings, pump and valve components, components for wet-process stations, and centrifuge parts.

Tefzel - Model ETFE - Ethylene Tetrafluoroethylene Modified Copolymer

ETFE (ethylene-tetrafluoroethylene modified copolymer) is often referred to by DuPont’s trade name, Tefzel®. ETFE provides excellent resistance to chemicals, abrasion, corrosion and weather as well as excellent mechanical strength and stiffness. It also has a low dielectric constant, uniform electrical properties, a continuous service temperature of 300° F and retains its abrasion resistance at temperatures ranging from -300° F to 300° F. Low friction and good electrical and thermal insulation also can be found in ETFE. Typical applications include cryogenics, compressor and pump linings and components, bearings, gaskets, wire insulation, electrical components, process vessels, wires and cables, and food and pharmaceutical packaging films.

Industrial Plastics - Glazing and Construction Materials

Aetna - Acrylic Sheet Materials

Long the standard by which all other transparent plastics are measured, acrylic sheet materials have served the needs of many industries for decades. Acrylics offer clarity, optical quality, long life and ease of fabrication in a wide variety of sizes, thicknesses and colors. Sheet, rod and tube are produced via casting or extrusion technologies, depending on the size or volume of product involved. Acrylics are available in specialized formulations or configurations to meet the needs of unique applications. Mar-resistant, impact strength enhanced and static dissipative products are examples of coatings or additives available for acrylics. Typical applications include point of purchase displays, signs, skylights, windows, safety guards and name plates to name a few.

Process Piping Systems - Plastic Piping Systems

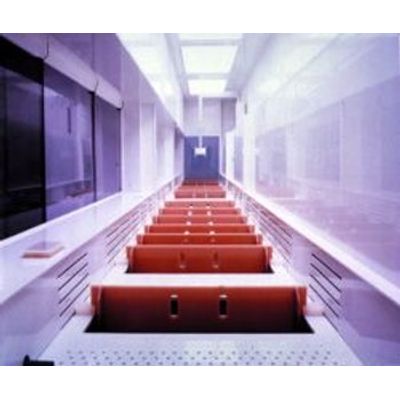

LabWaste - Model CPVC - Acid Waste Piping Drainage System

LabWaste CPVC Corrosive Waste Drainage System is a complete system of pipe, fittings & adapters specifically designed for waste chemical use. One of the key advantages of this system is its excellent resistance to a broad range of corrosive environments. CPVC is inert to most mineral acids, bases, salts and aliphatic hydrocarbons, and compares favorably to other non-metals in these chemical environments.

FLUOR-O-FLO - Model PTFE- XP - Acid Waste Clamp Joint Piping System

We are pleased to offer the FLUOR-O-FLO™ XP Clamp Joint Piping System. This is an ideal solution to drainage and other low pressure systems for difficult-to-handle fluids, providing safety, flexibility and extreme corrosion resistance.

Chem Proline - Chemical Piping Systems

Chem Proline is a new crack resistant polyethylene piping system designed for the harshest liquid chemical applications. Made from the latest generation of PE resin (PE100-RC), Chem Proline® pipe and fittings possess the greatest resistance to “slow crack growth.” Chem Proline® is a lower cost alternative to metal, fiberglass reinforced plastic pipe and lined steel pipe.

Aetna - Model PP - Thermoplastic Piping Systems

Polypropylene (PP) is a member of the polyolefin family and is one of the lightest plastics known. It possesses excellent chemical resistance to many acids, alkalis and organic solvents. PP is one of the best materials to use for systems exposed to varying PH levels, as many plastics do not handle both acids and bases well. It is not recommended for use with hydrocarbons and aromatics. Typical applications include water treatment, clean chemical processes, pharmaceutical operations, industrial plating, waste treatment systems and food processing applications.