- Home

- Companies

- AFT Sp. z o.o.

- Products

AFT Sp. z o.o. products

AFT Industrial

AFT - Model type DV - Flue Gas Damper Valve

Function: shut-off and control, Range: DN50 – DN10 000, Pressure: < 0.5 bar, Temperature: -20°C to +1 000°C, Options: design for lower temperatures,, special linings for high temperatures.

AFT - Model type LDV - Louver Flue Gas Damper Valve

Function: shut-off and control, Range: < 13 000 x 13 000 mm, Pressure: < 0.5 bar, Temperature: -20°C to +1000°C, Options: design for lower temperatures, special linings for high temperatures.

AFT - Model type DVH - Wafer Flue Gas Damper Valve

Function: shut-off and control, Range: DN50 – DN1 000, Pressure: < 0.5 bar, Temperature: -20°C to +1 000°C, Options: design for lower temperatures, special linings for high temperatures.

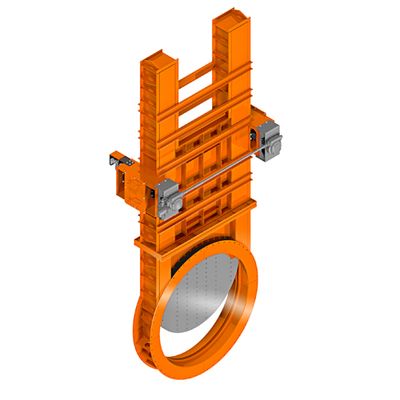

AFT - Guillotine Damper

Function: shut off, Range: DN150 – DN6 000 GDV, GDV-T type, < 6,000 x 6,000 mm GDV, GDV-T type, Pressure: < 0.5 bar, Temperature: -20°C to +750°C, Options: tandem version with sealing air system, special lining for high temperatures.

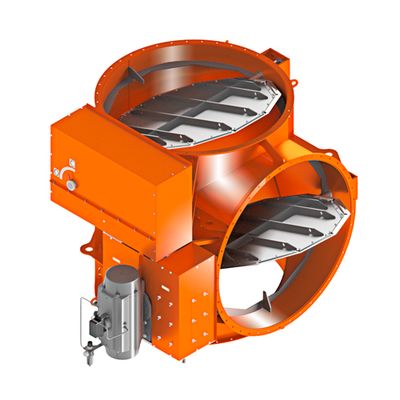

AFT - Model type DVR, DVR-T - Diverter / 3-Way Valve

Function: shut-off and control, Range: DN350–DN2 500, 350 x 350 — 2500 x 2500 mm, Pressure: < 0.5 bar, Temperature: -20°C to +750°C, Options: tandem version with, sealing air system.

AFT NOVAROTORS

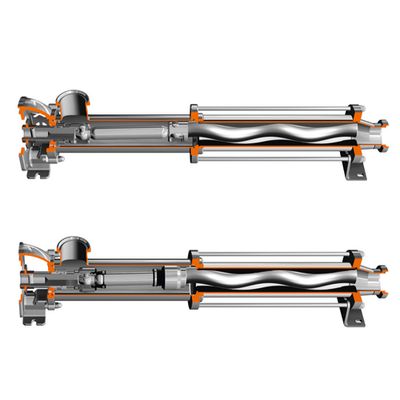

AFT - Model DN and JN Series - Standard Cavity Pumps

Capacity: 30l/h – 500 m3/h, Pressure up to 48 bar, Mounted vertically or horizontally, Modularity allowing adaptation to the existing installations, Low pulsation, uniform flow, Easy change in the flow direction allowed, simply by changing the direction of the rotation

AFT - Model DXO and DXC Series - Hygienic Cavity Pumps

Capacity: 30l/h – 300 m3/h, Pressure up to 48 bar, Mounted vertically or horizontally, Modularity allowing adaptation, to the existing installations, Open joint for maximal hygienic standard, and closed joint for the highest durability, Ready for CIP/SIP cleaning, Completely free of dead zones, Compliance with FDA, EHEDG and 3A.

AFT - Model DM Series - Metering Pumps

Capacity 0,1l/h – 30l/h, Pressure up to 24 bar, Modularity allowing adaptation, to required conditions, Accurate dosing without pulsation, or the use of control valves, Constant flow, independent of pressure, Best chemically resistant solutions.

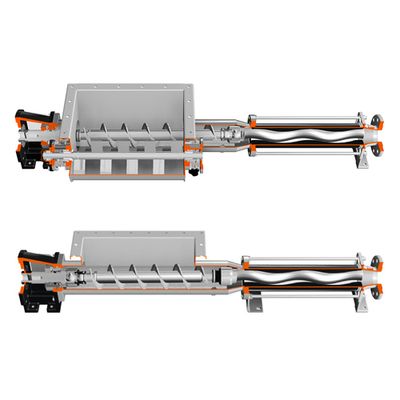

AFT - Model Series DH and JH - Cavity Pumps with Hopper

Capacity: 50 l/h – 500 m3/h, Pressures up to 36 bar, Pumping of products with high, viscosity and low flowability, Possibility to adjust the hopper, to individual requirements, Stroke and diameter of the feed screw, are adapted to conditions, Various pump variations are possible such as with, integrated trolley, built-in hopper with integrated, bridge breaker, with integrated feed screw.

AFT - Model TG Series - Macerators

Flow rate 1 m3/h – 100 m3/h, Two inspection ports as standard, Series of hardened knifes mounted, on two counter-rotating shafts, Simple maintenance,with easy access, to the cutting chamber, Easy access to the inside of the cutting chamber, Additional equipment: control panel, stone separator and many more.