AGICO Cement International Engineering Co., Ltd products

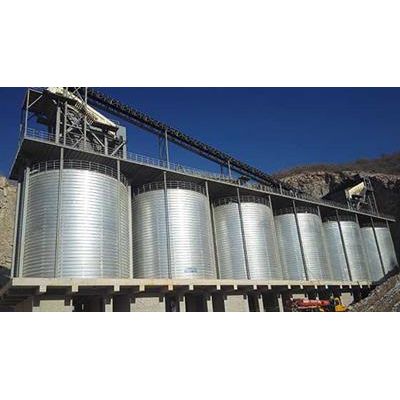

AGICO - Cement Storage Silo

Cement silo, also called cement bin, cement container or cement storage silo, is widely used in cement production plants for storing cement. Flyer steel silos are spiral silos with abundant technical strength and prominent performance, they are built with unique manufacturing method, professional equipment, and mechanized operation. Flyer cement storage silo is famous for its solid structure and durability.Cement silos are on-site storage containers used for the storage and distribution of various types of cement mixtures. Spiral steel silos for storing cement is an indispensable part in cement production industry. This type of cement silo has various capacities and sizes, making them the ideal storage solutions in many cement plants. Flyer Steel Silo is a professional manufacturer that produces high quality spiral cement silos and provides professional services from design, manufacture to install fitting according to the clients` requirements.

AGICO - Wastewater Storage Tank

Waste water treatment technology has got rapid progress in recent years. The purpose of the water treatment process is to remove contaminants that exist in the water, or reduce the concentration of such contaminants so the water becomes fit for its desired end-use. One of the most important uses is returning water that has been used back into the natural environment without adverse ecological impact.

AGICO - Chemical Storage Tanks

Chemicals storage silos are widely used in chemical industry for the storage of carbon black, activated carbon, calcined coke, urea, alumina, sodium carbonate, fly ash, desulphurization gypsum and other chemical products. Due to the perfect storage performance, the application of chemicals storage silos makes chemical materials more easily to be transported, stored and utilized. Therefore, chemical storage silos can not only streamline procedures but also contributes to the development of chemical industry.

AGICO - Industrial Powder Storage Silo

With good integral property and long service life, Flyer steel silo is used for storage of slag, mineral powder, fine powder and fly ash. The steel silo is constructed with special equipment when it was built. In the process of rolling, the ektexine of the silo was made to a spiral convex band with thickness five times more than the material, and width of 30 to 40 mm, which highly strengthened the carrying capacity of the silo, and make the overall intensity, stability as well as shock resistance preceding over other silos. Galvanized steel coil with strong anti-corrosion property is used to make the service life of Flyer steel silo longer than the other products. The diameter of the silo is 3-28m. The theoretical height can reach 30 meters.

AGICO - Lime Silo

Lime silo is one of the most commonly used methods for the lime storage industry. Flyer adopts advanced Germany silo construction technology, and the building technology is unique. When constructing, first feed the 495 mm wide coil sheet by a decoiling machine into a bending machine. Through bending, seaming, and then through the forming machine rolling into needed geometric shape, around the silo lateral forming a 30-40 mm wide, encircling spiral protruding strip on the structure playing the role of strengthening silo. For two different kinds of materials, silo construction equipment also can realize double bending processing.

AGICO - Slag Storage Silo

Slag storage silo or slag storage tank is specially used to store slag. Flyer’s slag steel silo is made of superior quality double-side galvanized steel sheets with spiral folding machines. Spiral steel silo, also called lipp silo, is the best steel structure for slag powder storage. It can be built on-site by our professional construction team. The spiral steel silo’s on ground foundation can be steel structure and concrete structure.

AGICO - Storage Silo for Calcined Petroleum Coke

Steel silos are very suitable for storing all grades of calcined petroleum coke (CPC). Our closed storage system solves many environmental pollution problems that may arise in CPC storage, and the environmental requirements will be fully met. In addition, our steel silos also have high economic and operational benefits.