Agr International, Inc. products

Glass

Agr - Model OmniLab - Automated Sampling and Testing System

The OmniLab® automated sampling system from Agr integrates two advanced measurement devices, the Dimensional Sampling Gauge 500 and the Sampling Pressure Tester 2, into a unified testing platform capable of interfacing with comprehensive plant-wide process control systems. This system facilitates both stand-alone operations and integration into production lines, allowing seamless, hands-free testing of up to 48 containers. The Dimensional Sampling Gauge 500 offers precise, automated weight and thickness assessment, while the proven Sampling Pressure Tester 2 ensures accurate volume and pressure testing. This integrated approach provides precise, mold-correlated data presented in a consolidated format, enhancing quality control for glass container manufacturers. It caters to the rigorous demands of industrial environments by offering high reliability and accuracy, contributing significantly to improved production efficiency and quality assessment through its comprehensive measurement capabilities.Agr - Model DSG500 - Dimensional Sampling Gauge for Glass Containers

The Dimensional Sampling Gauge 500 (DSG500) is a sophisticated measurement system designed for the precise evaluation of glass containers such as bottles and jars. It offers a comprehensive range of capabilities, including integrated thickness measurement and advanced optics. The device ensures high accuracy and reproducibility in measuring dimensional attributes, meeting stringent industry standards by achieving precision levels ten times greater than typical container design specifications. This system streamlines the measurement process by integrating over 30 different types of measurements into a single automated operation. Moreover, it is compatible with multiple line configurations and integrates seamlessly with Agr’s OmniLab® system, providing a holistic solution for dimensional, thickness, volume, and pressure assessments within the glass container manufacturing industry.Plastic

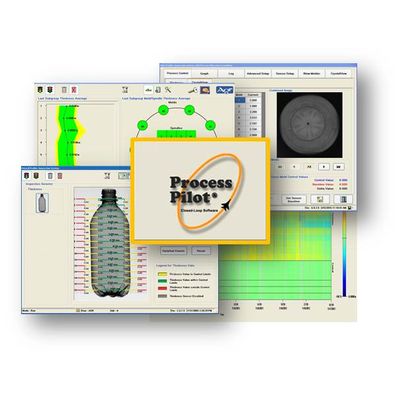

Agr - Process Pilot Total Process and Quality Control for PET Containers

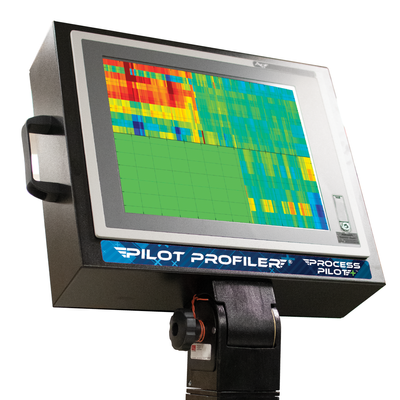

Agr International's Process Pilot family of products is engineered to provide comprehensive process and quality control specifically for PET containers. Offering a sophisticated blend of thickness distribution management, automated control of blowmolders, and material orientation optimization, these tools enable significant enhancements in efficiency and product quality. The system sets itself apart by utilizing direct feedback from bottle measurements, rather than relying merely on blowmolder performance metrics. Continuous monitoring and feedback mechanisms ensure the blowmolding process operates at optimal levels by automatically adjusting settings based on real-time data. Designed to uphold consistent quality and performance attributes in production, the Process Pilot system accommodates environmental, blowmolder, or material variations that might occur. The methodology involves measuring each bottle's material distribution with Agr’s Pilot Profiler, controlling blowmolder settings for consistent output, and optimizing material orientation using CrystalView software.Agr - Model Process Pilot+ - Automated Blowmolder Control System for PET Production

The Process Pilot+ automated blowmolder control system integrates both hardware and software components to interface with the Pilot Profiler measurement system, optimizing the PET container production process. It automatically regulates material distribution by adjusting the blowmolder settings, significantly reducing the need for manual intervention. The system provides precision control over the blowmolding process, resulting in enhanced bottle quality and reduced variability. By utilizing continuous feedback, it addresses common blowmolding issues such as maintaining lighter bottle standards with greater precision. This system also leads to substantial reductions in waste and improvements in statistical process metrics like Cpks and PPKs. With significant raw material savings and increased productivity, the payoff period for implementing this system is typically less than a year. The system's effectiveness in reducing start-up optimization time and improving bottle performance has prompted several companies, such as Suntory, to expand its use across multiple production lines.Other

Agr - Model Al - Dimensional Sampling Gauge for Aluminum Bottles

The Dimensional Sampling Gauge (DSG) by Agr International is an advanced, high-precision measurement system engineered for the automated dimensional gauging of aluminum bottles. Tailored for the aluminum bottle container manufacturing industry, the DSG-AL variant automates the process, enabling up to 48 bottles to be tested concurrently. This system mitigates manual intervention and enhances laboratory throughput through automated handling and testing. Essential for quality assurance, the DSG conducts comprehensive, critical measurements through its multifunctional station, specifically optimizing for the bottling industry. Its integration ensures precise data collection and analysis, crucial for maintaining the high-quality standards demanded in modern manufacturing processes.