Aikawa Fiber Technologies (AFT) Inc products

Performance Wear Components - Screen Cylinders

Shield Cylinder

AFT’s Shield™ cylinder is the latest innovation in screen cylinders – with the same accuracy and precision of our high performing MacroFlow2 but in a specially designed heavy-duty construction for the most demanding high wear applications. Made with duplex material especially resistant to abrasion, Shield is ideal for slotted coarse screening of recycled pulps and fine screening where abrasive materials are present, especially in tailing positions. As with the MacroFlow2, AFT’s proprietary locking system holds every wire in place in the laser-cut notches of the support ring. This unique assembly technology delivers slot width accuracy and precision beyond that of any other supplier, resulting in reliable performance over a long period of time.

Performance Wear Components - Screen Plates

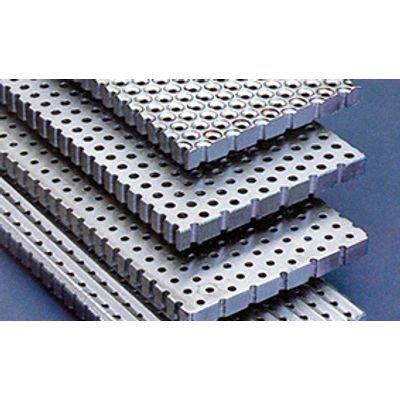

Drilled Plates

With over 110 years of experience in drilled plates, we pay attention to the details you need: Hole geometry (straight, conical, stepped, cylindrical, countersunk), Plate thickness (up to 25mm), Drilling pattern (we haven’t said no to one yet!), Profiles (AFT patterns and most paper industry OEMs), Materials (stainless, ferric, duplex and super austenitic grades), Open area (we work with you to be sure strength remains)

Slotted Plates

AFT provides a variety of slotted plates, mainly used for filtering applications such as extraction towers. Generally a slotted plate will be flat and precision cut. Plates can be manufactured in a variety of metallurgies as needed for a given application. In some cases plates are bent, while slot tolerances are still maintained. This type of manufacturing process can be expensive relative to a wedgewire or plastic design, and is generally used when an exact slot width is needed or a special metal is required for an application. Another advantage for a slotted plate is that it can be made in a variety of thicknesses to meet strength requirements.

Performance Wear Components - Screen Rotors

Energy Smart Rotors

The screen rotor affects every aspect of screening performance: Power usage, Fiber recovery, Debris removal. The GHC is an award winning rotor and known as one of the best on the market today for energy efficiency in fiber screening. This rotor is best suited for recycled fiber and virgin kraft brownstock screening. Our latest design - the GHC2 - has out-performed the competition with energy saving of more than 30%. The secret to this unique design is in the rotor elements, where the rotor causes micro level turbulences resulting in a higher efficiency. By preventing the pulp from thickening, runnability is improved and energy consumption is reduced. The GHC2 rotor provides an optimal balance of turbulence and negative pressure pulsations to ensure energy-efficient and reliable screen operation. The bottom line is a cleaner pulp using less energy.