Air Techniques, Inc., (ATI) services

Stacks

Design & Engineering Services

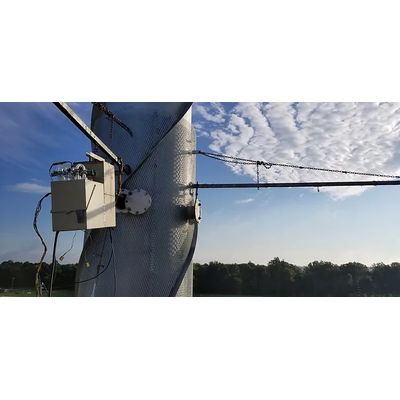

Air Techniques is proud of its history designing steel stacks systems and the componentry, equipment and facilifites related to the stack systems. From the first stack over 25 years ago to the current stack projects, our design and project engineering are the focal point of the stack business. The engineers of ATI and of our sister company, AERI, work together to provide safe, efficient and cost effective steel stack systems for industry. From small diameter boiler economizer supported stacks to large 14` diameter to 250` tall major stack projects, ATI engineers are known for their quality, convervative designs.

Stack Installation & Support Services

Many stack purchasers desire total turnkey services to include the design, supply, delivery and installation of the stack system. Air Techniques, over 80 years ago, provided our first installed steel stack with complete success. Since those early days we have completed numerous successful turnkey projects for stacks of all sizes and arrangements. We hold contractor licenses in several states and continue to add to this list.

Services - CEM Sytems & Integration

Industrial & Utility Construction Services

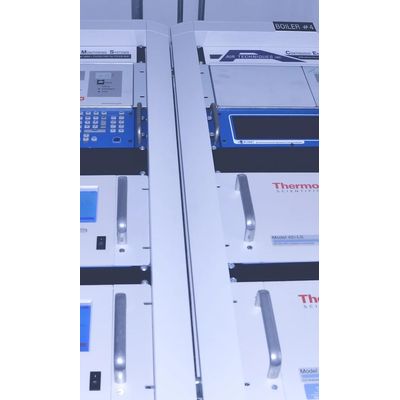

Built to withstand Any Climate. ATI CEMS Systems are built specifically for the harsh industrial and utility environments and able to withstand the conditions from the hot and humid south to bitter cold in the upper Midwest. Our quality is unmatched and our robust systems are designed for longevity, durability & ease of service.

Designed With Service In Mind

Each ATI CEMS cabinet and interior is designed with service in mind. Industry best practices include Panduit and prodigious labeling as our standard. This results in an open and fully accessible installation, longer service life & ability to more quickly troubleshoot and access system components. Our industrial grade panels include touch screen operation and the control and data system is designed using current technologies (i.e. Win 10/11, DisplayLink Touchscreens, open standards for communication protocols)

ATI CEMS Maintenance & Reporting Services

CEMS - Maintenance Service

Our field service team is your go-to solution leading to dependable operation and minimizing unplanned downtime. We recommend quarterly inspections and service to ensure your CEM System operates with the highest uptime and repeatability. ATI CEMS has the resources and expertise to assist your team with immediate solutions & results for trouble-free operation. Issues that can potentially interrupt reliable operation of the CEMS can be avoided with the assistance of our attentive trained service technicians and implementation of customer preventative maintenance program that we will help you develop.

CEMS - Reporting Services

Air Techniques provides a full menu of reporting services. These reporting services ensure complete compliance with your individual Title V air permit requirements. These include, but are not limited to, CFR (Code of Federal Regulations) Part 60, Part 63, Part 75, or Part 503 as well as specific state regulations nationwide. We have over 30 + years experience in authoring quarterly CEMS reports for our customers. Our EPA reporting expertise and efficiency make this process less painful and return you, the customer, to operating your plant.

CEMS Repairs & Remote Support

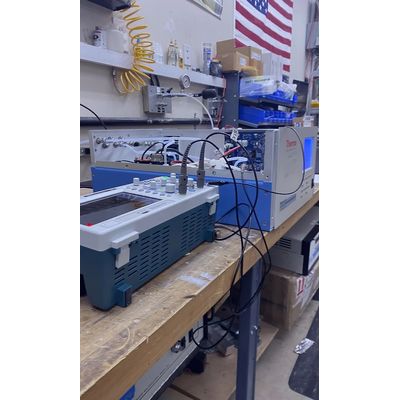

ATI CEMS - Analyzer & Equipment Repairs Services

ATI CEMS offers a wide range of services, including analyzer and equipment repairs & programming (DAH`s, PLC`s, & COMS). Our CEMS Technicians are available by phone 24/7 for all of your CEMS needs and questions.

ATI CEMS - Robust Remote System Support Services

ATI CEMS has immediate solutions through 24/7 remote system support which allows for predictive maintenance & the ability to receive push notification for failures in equipment.

ATI Testing

ATI - Mobile CEMS Applications

Certification (RA) and annual recertification (RATA) of stationary CEM monitors. CEMS performance specification tests. Developmental testing programs for PEM system applications. Control equipment source compliance test. Combustion process studies for NO and CO emissions. Annual NO monitoring of boiler and generator systems. Incinerator VOC destruction efficiency testing. System VOC capture efficiency testing.

ATI - Process Specific Testing Services

Annual NO monitoring of boiler and generator systems. NO , CO, VOC, PM & HAP emissions testing required for the wood products industry. VOC destruction efficiency testing of oxidizer systems. Relative accuracy test audits (RATA) of CEM Systems. NO , CO & NMHC Emissions testing of engines.