ALD Vacuum Technologies GmbH products

Vacuum Metallurgy

ALD - Vacuum Induction Melting & Casting Systems

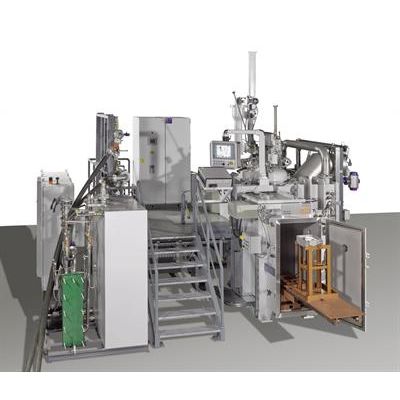

Vacuum Induction Melting & Casting Systems for Charge Weights from 1 up to 750 kg for R&D and Pilot-Scale Production. ALD Vacuum Technology GmbH designs, engineers and manufactures a variety of small vacuum induction melting & casting systems used to produce high-quality metal alloys for R&D and pilot scale production. ALD has extensive experience in combining various melting technologies with casting systems to address specific material requirements and to produce alloys with different geometries. ALD’s history as a VIM technology leader includes experience in delivering small scale VIM systems to leading R&D institutes and specialty metal alloy producers throughout the world.

ALD - Vacuum Induction Degassing Furnaces

Vacuum Induction Degassing (VID) furnaces have been developed for special applications in the ferrous and non-ferrous metals industry for charge weights up to 30 tons. VID furnaces are compact, simplified and cost-effective vacuum induction melting furnaces. They are most suitable for production of steels and other alloys requiring melting, liquid metal refining and degassing in vacuum, while still allowing pouring the melt in air. VID furnaces are an attractive alternative to commonly applied secondary metallurgical systems such as ladle and vacuum degassing furnace (LF/VD furnaces). VID furnaces are particularly valuable to the alloy manufacturer for smaller heats up to 30 t based on their flexibility and lower cost production.

ALD - Vacuum Arc Remelting Furnaces (VAR)

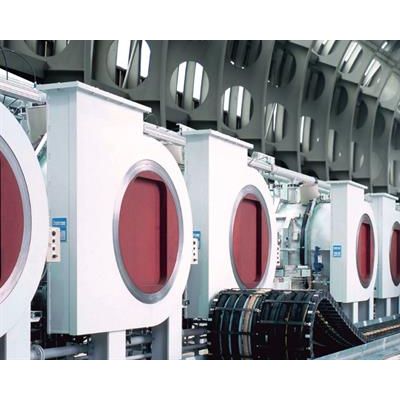

VAR is widely used to improve the cleanliness and refine the structure of standard air-melted, vacuum induction melted or ESR remelted ingots. VAR steels and superalloys as well as titanium, zirconium and their alloys are used in a great number of high integrity applications where cleanliness, homogeneity, improved fatigue and fracture toughness of the final product are essential. Aerospace, power generation, defense, medical and nuclear industries rely on the properties and performance of these advanced remelted materials.

Vacuum Heat Treatment

DualTherm - Dual Chamber Vacuum Furnace for Flexible Heat Treatment

The ALD DualTherm furnace is the ideal multi-purpose vacuum chamber furnace for use in near-series production as well as in flexible production with alternating processes.

ModulTherm - Vacuum Heat Treatment System with High Pressure Gas Quenching

ALD ModulTherm® heat treatment technology has been used successfully worldwide for many years and is the preferred method for the heat treatment of new transmissions and diesel injection systems in the automobile industry.

SyncroTherm - Vacuum Furnaces

The new SyncroTherm® – unit from ALD Vacuum Technologies provides for the first time the complete and total integration of heat treatment into the manufacturing work center. With this unit, the case hardening process is fully synchronized with the cycle of soft-machining, therefore allowing a continuous “One-Piece Flow”.

MonoTherm - Vacuum-Chamber Furnace

The vacuum furnace ALD MonoTherm has reproducible heat treatment capabilities with high efficiency and can be flexibly adapted to customer’s specific requirements.

ALD - Vacuum Sintering Plants

Vacuum Sintering Plants for Dewaxing, Sintering and Overpressure Sintering. ALD Vacuum Technologies has developed and built sintering plants for hard metals, cermets and other PM-materials for more than 50 years. The use of the latest technologies results in the improved and lasting quality of the sintering products. Substantial savings in process time leads to much higher productivity and cost reduction.