Alformet GmbH products

Fibers

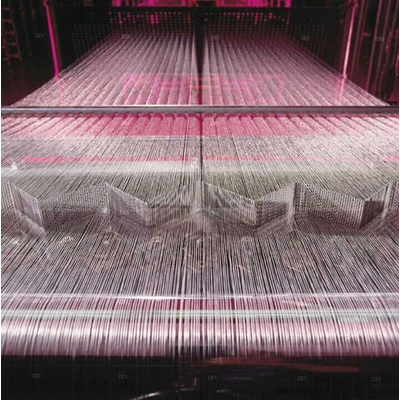

Alformet - Glass Fiber for Reinforcement in Composites

Glass fiber consists of numerous extremely fine strands of glass and is characterized by mechanical properties that are advantageous in various applications. Although it lacks the rigidity of carbon fiber, glass fiber remains a cost-effective and notably less brittle option, especially when utilized in composite materials. These fibers serve as reinforcing agents in various polymer products, contributing to the creation of strong yet lightweight fiber-reinforced polymer composites, often known as fiberglass. An efficient structural component, glass fiber is valued for its strength-to-weight ratio. The fibers are extruded from silica-based or other glass-like formations into thin strands with small diameters. Commonly used types include E-glass, C-glass, and S-glass, each offering specific properties suitable for different engineering applications.

Thermoplastics

Alformet - High Density Polyethylene (HDPE) Polymers

High Density Polyethylene (HDPE) is a versatile, semi-crystalline thermoplastic known for its robustness and excellent chemical resistance. Due to its structure, HDPE offers a combination of flexibility and strength, making it suitable for a wide range of applications including piping systems, bottles, and geomembranes. Though not as strong or heat-resistant as some other plastics, HDPE's resilience in chemically challenging environments makes it an optimal choice for industries seeking durable solutions. It serves crucial roles in packaging, construction, and even in agricultural applications due to its ability to withstand varying conditions without compromising its structural integrity. The material stands out for its ease of processing and comparatively lower cost, providing an efficient option for bulk applications requiring substantial toughness.

Alformet - Polyamide (PA) Thermoplastic

Polyamide, widely recognized as nylon, is a crucial semi-crystalline thermoplastic appreciated for its low density and high thermal stability. The unique numbering system identifies various types of nylon, such as 6, 66, 11, and 12, which correspond to distinct molecular structures that result in varied properties. Notably, Nylon 6 and Nylon 66 are the most frequently utilized. PA's attributes like wear resistance, favorable friction coefficient, and exceptional temperature and impact tolerance make it a preferred choice for replacing metal in applications. These include automotive components, industrial valves, and railway insulators, where high strength and reduced weight are critical. Despite its superior characteristics, nylon tends to absorb moisture affecting its dimensional stability. Different polyamide types absorb moisture variably, influencing their properties. Furthermore, Nylon’s chemical and oil resistance enhances its appeal in industrial use, though attention to moisture absorption is necessary for maintaining performance.