- High Performance Materials and Components - Forged Products

- High Performance Materials and Components - Specialty Materials

- Advanced Alloys and Solutions - Specialty Alloys + Components

- Advanced Alloys and Solutions - Specialty Rolled Products

- Advanced Alloys and Solutions - Standard Stainless Sheet Products

Allegheny Technologies Incorporated (ATI) products

High Performance Materials and Components - Forged Products

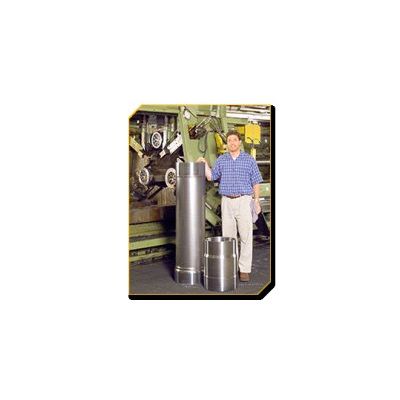

ATI - Flowforming for High-Performance Applications

We are the world leader in flowforming, a cold metal forming process that produces seamless, symmetrical, tubular shapes for precision components in military, aerospace, oil/gas and other applications. Flowforming often saves material and machining operations, ultimately reducing component costs. We have the world’s most comprehensive capabilities, and are experienced in more than 50 metals, including advanced alloys that are typically difficult to form. Our operation includes patented, proprietary flowforming machines as well as industry-leading cutting, hot forging, hydraulic pressing, tube bending, non-destructive testing and metallurgical testing capabilities. As a vertically integrated ATI business, we can offer our customers complete net-shape components made to final print.

ATI - Isothermal Forgings

Our isothermal forging capability in Cudahy, Wisconsin features three isothermal presses, including one of the world`s largest isothermal presses. The unique design of this strain-controlled, high-tonnage press, rated at 12,500 tons, allows it to forge larger-diameter, close tolerance forgings required for today`s high efficiency jet engines. Our patented SuperCooler™ technology enables us to produce highly sophisticated components that have differing mechanical properties in different parts of the same piece for greater resistance to fatigue and temperature effects.

High Performance Materials and Components - Specialty Materials

ATI - Nickel & Cobalt Alloy

ATI 718Plus alloy is a precipitation hardened nickel-base superalloy that exhibits a combination of superior high temperature properties and good fabricability.

Advanced Alloys and Solutions - Specialty Alloys + Components

ATI - Machined Components

ATI provides a comprehensive network of machining and subassembly capabilities that convert forged, cast and fabricated shapes into application-ready components, providing a final link in the secure ATI supply chain. ATI machining and finishing capabilities are focused especially on titanium, nickel-based alloys and other high performance materials used for aerospace, defense, oil & gas and other applications.

Advanced Alloys and Solutions - Specialty Rolled Products

ATI - Nonmagnetic Stainless Steels

ATI 9 plate is a nonmagnetic, high tensile strength steel, which displays high toughness and outstanding wear resistance for an austenitic steel. It is similar to the Hadfield steel family except it contains nominal 4.40% Cr and 3.25% Ni whose presence increase corrosion resistance relative to Hadfield steels. As with the Hadfield steels, ATI 9™ alloy exhibits a high work hardening rate. Applications include winding drums for steel cables, coal chutes, mine cars, coal stripping equipment, earth moving equipment, rail car parts, housings for magnets and transformer wedges.

Advanced Alloys and Solutions - Standard Stainless Sheet Products

ATI - Ferritic Stainless Steels

ATI`s AL 18CrCb™ stainless steel is a heat-resisting ferritic grade providing good oxidation and corrosion resistance for applications like automotive exhaust system components. Ferritic alloys are not inherently strong at elevated temperatures, but columbium additions coupled with appropriate solution annealing markedly improve long-time creep-rupture strength properties ATI 18CrCb™ alloy is dual stabilized with columbium and titanium to provide good weld ductility and resistance to intergranular corrosion in the weld heat affected zone. ATI 18CrCb™ alloy has been developed for the severe tube bending and forming operations typical in automotive exhaust manifold fabrication. Tight control on carbon and nitrogen levels plus improved mill processing result in enhanced formability in terms of higher tube bending speeds and lower breakage or scrap rate.