- Home

- Companies

- Amec Industries TR

- Products

Amec Industries TR products

Amec - Modular Oxygen Generator

Our modular oxygen generators are designed for users whose oxygen consumption tends to increase over time. The lowest production capacity is 2.5 Nm3 / h and the maximum production capacity of a single machine is up to 15 m3 / h. Production capacity can be increased up to 150 m3 / h thanks to the modules that are added side by side after 15 m3 / h capacity.

Amec - Oxygen Generator

twin tower oxygen generators are the machines we would consider conventional. Many oxygen generators in the world have twin tower designs. They perform well in harsh working environments.

Amec - Modular Nitrogen Generator

Our modular nitrogen generators are designed for users whose nitrogen consumption tends to increase over time. Thanks to its aluminum carbon molecular sieve tanks, it has been serving for years with maximum performance without corrosion. It has minimum air consumption and minimum pressure loss thanks to its uniquely proportioned CMS tanks.

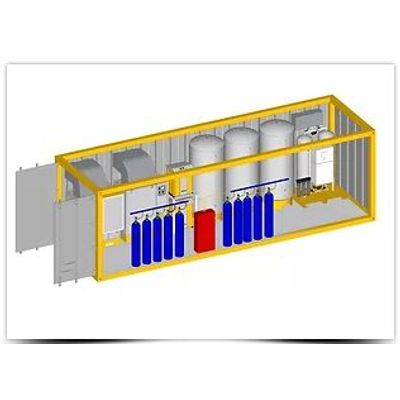

Amec - Container Oxygen Production System

Our plug-and-play chassis oxygen generation systems are delivered after all mechanical and electrical manufacturing. There is no need for any electrical and mechanical assembly after shipment. It is only connected to the power distribution panel and is ready for use. Skid oxygen generation systems have a small footprint, are easy to transport and the commissioning procedure is very simple. Skid systems can be manufactured for all capacities. Please contact our sales engineer for your requests.

Amec - Oil Free Oxygen & Nitrogen Booster

It is used to fill the oxygen gas you have produced to high pressure cylinders with 150 bar pressure. Our oxygen boosters have two different designs: direct coupled and belt-pulley drive mechanism. It is carefully manufactured from aluminum and stainless steel parts with high corrosion resistance. Our oxygen boosters are used safely by many organizations around the world.

Amec - Compressed Air Dryer

Refrigerant type dryers are used to separate the water vapor in the compressed air from the compressed air by condensing it. Compressed air dryers have three different working principles as membrane, desiccant and refrigerant type. Compressed air can be dried up to +3 C dew point in refrigerant type dryers, while it can be dried down to -40 and -70 C dew values in desiccant type air dryers. Desiccant air dryers are divided into two types: with air loss and without air loss (with heater). In both models, the degree of dryness can reach -40 or -70 C.

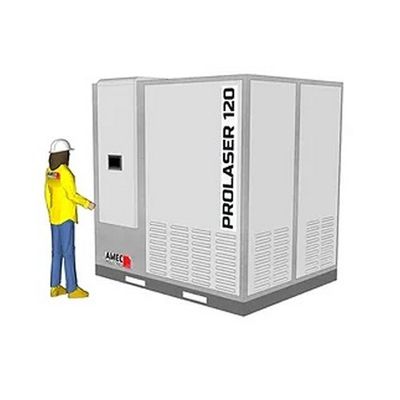

Amec - Laser Cutting Nitrogen Production System

Our compactly designed PROLASER Our Nitrogen Production Systems are designed for businesses that have space problems. Prolaser Nitrogen Production Systems are delivered complete with all mechanical and electrical fabrications. There is no need for any electrical and mechanical assembly after shipment. All equipment required for the operation of the system are located in the sound and heat insulated cabin.