Amerair Industries, LLC products

Dry Filtration Baghouses

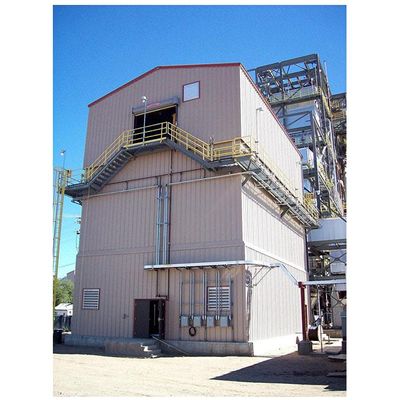

Amerair - Negative Pressure Penthouse Roof Enclosed Pulse Jet Baghouse

Negative pressure penthouse roof enclosed Pulse Jet Baghouse designed to filter 406,000 ACFM of ash laden flue gases from a 105 egawatt cogenerating facility. This midwest US installation is equipped with 17 ounce polyphenylsulfide (PPS) filter bags with single top removal clean air plenum doors for ease of maintenance.

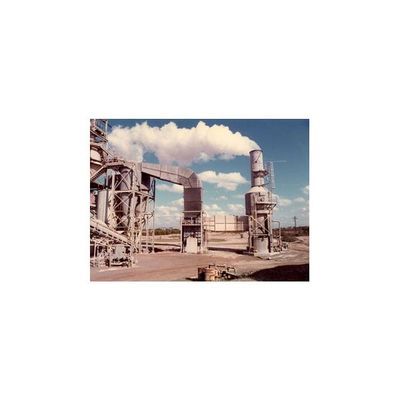

Amerair - Sixty Five Megawatt Utility Power Boiler Baghouse

Sixty Five Megawatt Utility Power Boiler Baghouse designed to filter 225,000 ACFM at 325°F. The eight module baghouse incorporates long bag cleaning technology and penthouse plenum top removal door system for ease of maintenance. The flue gas filtered is generated from the circulated fluid bed combustion of various blends of low to medium sulfur coal. The filter media is laminated with a PTFE membrane to provide very low outlet emissions.

Other Products

Amerair - Circulating Dry Scrubber

Amerair is pleased to announce the introduction of Circulating Dry Scrubber technology to its complete line of acid gas control products. Based on the experience of its resident personnel who have applied this process on a number of high SO2 and HCl applications, Amerair has developed its own optimized version of this process.

Amerair - Dry Injection Scrubbing System

Amerair offers a wide variety of dry injection scrubbing systems which provide very economical control solutions where hydrogen chloride, hydrogen fluoride, sulfur dioxide, bromides, mercury, furans and dioxins are present in the outlet emissions. Depending upon the effluent and its concentration in the gas stream, removal efficiencies can vary widely from fifty to the high ninety percent range.

Amerair - Activated Carbon Injection (ACI) Systems

Amerair Industries presents its line of standardized Activated Carbon (ACI) injection systems for Mercury, Dioxin/Furan emissions compliance. All of Amerair’s systems are offered with full emissions performance and reagent utilization guarantees. Amerair’s staff of experts have experience in applications from Industrial and Utility Boiler MACT compliance as well as Electric Arc Furnace, Cement Kiln and other industrial applications.

Amerair - Combination Semi-Dry & Wet Acid Gas

Amerair combines and utilizes its semi-dry and wet scrubbing capabilities and experience to provide a highly efficient acid gas scrubbing system without the extreme complexity and expense of large wet limestone scrubbing systems. This technology and know-how can be extremely valuable when considering sulfur dioxide generation associated with high sulfur coal combustion where SO2 scrubbing efficiencies of 95-99%+ are required.

Amerair - Wet Scrubbers for Particulate Control, Gas Absorption and Heat Recovery

Amerair manufactures a complete line of wet scrubbers for particulate control, gas absorption and heat recovery. Our dedicated staff of professionals have successfully installed numerous scrubbers in a variety of industries over the last thirty years. Some of these industries include: steel and non-ferrous metals, pulp and paper, mining and minerals, industrial power and steam generation, incineration, food process, chemicals and several others. Amerair provides a wide variety of scrubber designs for the most difficult process applications. Because all of our scrubbers are custom engineered to meet the client’s process requirements, a combination of technologies may be required to achieve the desired outlet emission criteria.

Amerair - Cyclone Collectors

Amerair provides custom designed cyclone configurations to satisfy customer specific application requirement for efficiency, pressure drop and layout limitations. These cyclones utilize either tangential inlet or voluted inlets, vertical or horizontal outlets, and individual dust discharges or common hoppers. Customized designs provide optimization of size for plant layout considerations, minimal pressure drop and maximum efficiency. Cyclones in single or multiple unit configurations are available in a variety of steel construction materials including carbon, abrasion resistant, stainless and other alloys. A number of different linings can be supplied for abrasive or high temperature service.