American Carbon Company products

Cathodic Protection

ACC - Model BADGERCOMP - Graphite Anodes for Corrosion Protection

BADGERCOMP Graphite Anodes are essential components designed for robust corrosion protection across various industries. These anodes are manufactured with advanced technology, employing calcined petroleum coke and coal tar pitch as key materials. The production process includes precise graphitization and machining, ensuring graphite rods meet stringent size and tolerance standards. These anodes offer exceptional durability, resisting harsh environmental conditions to extend the lifespan of industrial assets. With applications in fields such as oil and gas, water treatment, marine, and power generation, these anodes enable the protection of infrastructure against corrosive elements. Moreover, American Carbon Company provides customized graphite anode solutions to meet specific industry requirements, ensuring high performance and efficiency in cathodic protection systems. BADGERCOMP Graphite Anodes support innovations in energy storage, portable electronics, and more, with their enhanced conductivity and stability.ACC - Model BADGERCAST - High Silicon Cast Iron Anodes for Corrosion Protection

The BADGERCAST High Silicon Cast Iron (HSCI) Anodes, designed by American Carbon Company, provide a robust solution for combating corrosion across a variety of industries. Engineered from a premium blend of silicon, iron, and chromium, these anodes offer exceptional corrosion resistance, making them ideal for marine, industrial, and infrastructure applications. BADGERCAST anodes are known for their longevity and durability, reducing maintenance costs and offering consistent protection over time. The versatile nature of these anodes allows for application in offshore structures, pipelines, and water treatment facilities, showcasing adaptability to diverse conditions, including deep ground beds with natural groundwater. BADGERCAST anodes have proven stability and a capacity to be installed with or without coke backfill, optimizing installation based on soil composition. They are an efficient choice for safeguarding assets, demonstrating superior electrochemical performance and decreasing the required number of anodes per installation, enhancing the overall corrosion protection system's effectiveness.Advanced Materials

ACC - Graphene Applications in Advanced Materials

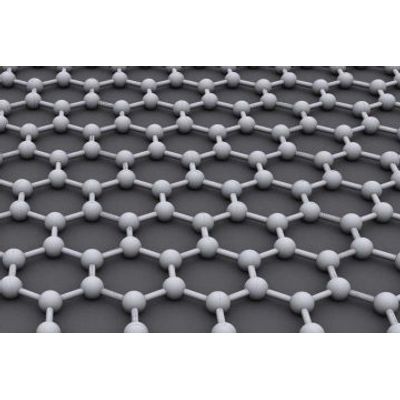

American Carbon is at the forefront of this emerging nano-material. Our team of researchers and product developers have been working with a number of laboratories, product manufacturers, and end-users to develop products that are economically viable for commercial applications in today’s market. There is no doubt that graphene is on a trajectory to significantly change the world as we know it today. By strict definition graphene is a one atom thick nano particle connected in a honeycomb lattice structure. When compared to steel, it is over 100 times stronger by size (and a University of Massachusetts study found it may be able to absorb as much as 10 time more energy before failing) When compared to copper, graphene is much more electronically conductive (although much more brittle). And finally, graphene is rewriting Fournier’s law of thermal conduction which defines how a solid absorbs heat. While these three amazing discoveries are impressive by themselves, the nearly invisible nature of the structure leads to nearly unlimited applications to better everyday products from electronics to lubricants to coatings and even water treatment.

ACC - Specialty Graphite

American Carbon Company focuses on providing machinable raw materials to the specialty graphite industry. With a wide variety of density and material properties, we are sure to offer the correct material to fit your specific needs. From low density extruded and molded graphites to high end isostatically (or isotrophic) molded graphite, we have the ability to match any specification. Having many different grades allows American Carbon to be a provider of graphite to a diverse range of industries. This wide application base has helped find synergies between uses to better meet the needs of customers.