- Home

- Companies

- Andamine Group

- Products

Andamine Group products

Stone Crusher Plant

Andamine - Andesite Stationary Crusher Plant

Andamine stationary crushed stone plant can be used to create a solution exactly according to our production needs. Moreover, this crushing plant is equipped with a remote control, which can regulate the dosing speed and is very convenient to operate.

Andamine - Granite Stationary Crushing Plant

The customer has shape and size requirements for various aggregates and stones in the finished product. According to the customer’s budget and profitability, we configured the impact crusher to increase the output of medium and large-sized stone materials.

Andamine - Basalt Stationary Stone Crusher Plant

Capacity: 100 tons per hour. Raw material size: ≤500mm. Finished product specifications: 0-5, 5-12, 12-25, 25-38mm.

Mobile Crusher Plant

Andamine - Combined Mobile Crusher Plant

Combined mobile crusher plant revolutionizes on-site material processing with its compact design and integrated crushing functions. Andamine offers various combined mobile crushers to meet different crushing needs, from coarse to fine. With advanced automation and flexible configurations, these mobile units handle diverse materials efficiently. Their mobility allows quick setup and easy relocation—ideal for dynamic construction and quarrying projects. It’s a smart, cost-effective solution for modern crushing demands.

Andamine - Mobile Jaw Crusher

Mobile jaw crusher offers strong crushing power, easy mobility, and fast setup—ideal for on-site crushing in construction and mining. Its compact design handles tough materials like concrete and granite efficiently. Perfect for dynamic projects, it reduces transport costs and boosts productivity, making it a smart, flexible solution for modern crushing demands.

Andamine - Mobile Impact Crusher

A mobile impact crusher, typically used in the secondary or tertiary crushing stage of a crushing process, is a crushing equipment with impacts designed to crush an array of materials, which can be used in construction waste, mining, railways, highways and other fields. In the following, there will be more specific details about this kind of the mobile impact crushers. Now we come to learn about what is a mobile impact crusher.

Andamine - Mobile Cone Crusher

The mobile cone crusher is specially designed for high hardness stone (such as granite, basalt, quartz sandstone, etc.), and can handle hard and medium-hard materials with compressive strength ≤350MPa. It is equipped with the principle of laminar crushing to realize highly efficient fine crushing, and the finished product has a high rate of cubic granularity. Its intelligent control system can be adapted to complex working conditions, especially suitable for mining slopes, construction solid waste recycling and other scenarios in the demand for high wear resistance, continuous operation stability and precise control of particle size.

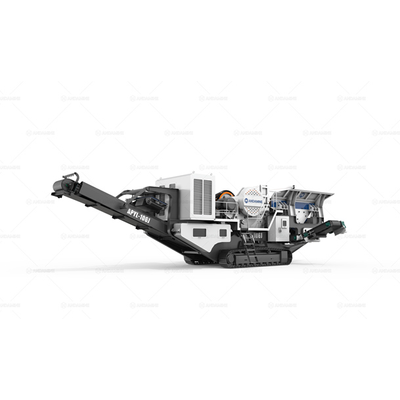

Andamine - Track Crusher

A track crusher, also known as a crawler mobile crusher, is a high-efficiency crushing equipment that relies on tracks for transferring. Designed to adapt to various harsh environments, including climbing operations, it excels in complex terrain. Whether you’re on flat ground or navigating a muddy mountain road, the tracked mobile crusher can seamlessly move between different locations, eliminating the need for additional transport and helping you complete diverse crushing tasks with ease.

Sand Making and Washing

Andamine - Sand Making and Washing Plant

Sand making and washing is also called sand making and washing line. And the sand crushing plant is a kind of special equipment for producing construction sand and stone. The sand production process is often needed in many fields, and this processing line can meet the requirements of simultaneous production of stone and artificial sand.

Andamine - Vertical Shaft Impactor (VSI) Crusher

A VSI Crusher (Vertical Shaft Impactor) is a high-efficiency rock crushing machine that utilizes a high-speed rotor to accelerate material into a crushing chamber, where impact forces fracture particles through rock-on-rock or rock-on-steel collisions. This versatile equipment excels at refining irregular aggregates into uniformly shaped, cubical end products while simultaneously reducing material moisture content. VSI crushers are the preferred solution for producing premium-quality manufactured sand (M-Sand) and precisely graded aggregates for concrete, asphalt, and road base applications, delivering superior particle shape and size control compared to conventional crushers.