Anderson International Corp products

Oilseed Equipment

Anderson - Dry Oilseed EXtruder

The Dox (Dry Oilseed EXtruder) is designed to mechanically shear, cook, and dry the material being processed for improved oil recovery. The high-shear environment ruptures the oil-containing bodies within the oilseed and generates frictional heat. This heat deactivates harmful enzymes within the oilseed, flash-dries excess moisture, and cooks the proteins for a more efficient pressing.

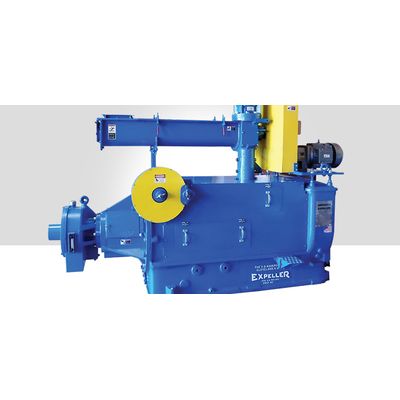

Anderson - Oil Expeller Presses

The new line of Anderson Oil Expeller presses are designed to continue Anderson’s long-standing tradition of providing the industry with the most durable and efficient mechanical screw presses on the market. Along with maintenance- and operator-friendly packages, the systems can press over 100 metric tons per day (MTPD) in a single machine with residuals as low as 5% when paired with Anderson’s extrusion technology. With minimal modifications the Anderson Oil Expeller presses can change from one oilseed application to another, allowing for adaptation to market shifts and fluctuation. In addition, the machinery limits the downtime required for maintenance, increasing the profitability of the press.

Anderson - Expander

Designed to improve the efficiency of oil recovery in solvent extraction. The Anderson Solvex packs material to be extracted into a dense, yet very porous structure. This allows the solvent easier access to the oil, resulting in up to 50% increases in extractor capacity, 40% reduction in solvent hold-up in the solid product (marc), 20% reduction in solvent in the liquid product (miscella), and an overall reduction in solvent losses. Expanders, like the Solvex, lower overall plant energy consumption and loading on the extractor, hence reducing their operational costs and increasing their capacity. The Solvex Expander can also reform dense pre-press cake into a porous collet for improved extractor efficiency on high oil content materials, providing similar benefits as with soybeans.

Anderson - Expeller

The most durable press in the oilseed extraction industry today. With earlier models from the 1920s still in operation today, the Duo™ Series Expeller® presses are hands down the most durable and long-lasting presses ever produced for the vegetable oil/oilseed extraction industry. No press has been more widely used on a greater variety of applications than the Duo. The Duo Series Expeller is ideal for capacities of 10-30 tons per day on difficult-to-process specialty materials such as corn germ, coffee beans, sesame seed, and grapeseed. The unique dual pressing design allows for lowest possible residual oil levels in a single pass.

Polymer Equipment

Expeller - Presses

The most economical method of removing water from synthetic rubber is a mechanical screw press like the Expeller. Anderson’s Moisture Expeller press was invented to provide processors with a new technology for separating process moisture from fresh crumb rubber (synthetic or natural). The continuous process “squeezes” the compressible rubber by means of a rotating interrupted screw, adjustable cylindrical elongated barrel with drainage bars, and an adjustable discharge mechanism, thus permitting the noncompressible water to flow from the process to water recovery systems. The crumb rubber containing 40-60% moisture at feed is effectively dewatered to 6 to 15% water by weight at discharge. The discharging dewatered crumb is then fed to the inlet hopper of Anderson’s Expander/Dryer.