- Home

- Companies

- Applied Catalysts

- Products

Applied Catalysts products

Monolithic Catalysts

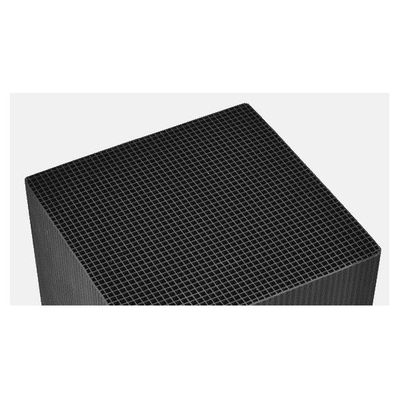

Applied Catalysts - Model ACMC - Activated Carbon Monolith Catalysts for Process Catalysis

Do you want to make more product in less time? Would you like to see improved selectivity in your process? Do you want fewer catalyst change outs due to less catalyst attrition? Applied Catalysts develops and manufactures ACMC® (activated carbon monolith catalysts) based on a unique activated carbon monolith. These catalysts are used for a number of applications including chemical process and emission control catalysts. In chemical process applications, ACMC® catalysts can be used for continuous hydrogenation reactions in many areas where traditional GACC (granular activated carbon catalysts) are currently used. Other applications where ACMC is used include indoor air quality, ozone reduction, and odor elimination for emission control and dehydrogenation, dehalogenation, syngas to alcohols, and other specialty areas for chemical process.

Applied Catalysts - Ceramic Monoliths for Air Pollution Control

Applied Catalysts manufactures a wide variety of ABATE VOC ceramic monolith supported catalysts. Monolithic catalyst supports are honeycomb structures with many small “cells”, or parallel channels that allow exhaust gases to run axially through the catalyst. Monoliths are sometimes called “flow-through” substrates. Exhaust gases flowing through the cells contact the catalyst surface which has been coated onto the cell walls. The major advantages of monolithic supports include high geometric surface area (GSA) per unit volume (small compact design for a catalytic oxidizer), large open frontal area (low pressure drop), and excellent attrition resistance (robust design).

Applied Catalysts - Metal Monoliths for Air Pollution Control

Applied Catalysts manufactures a wide variety of ABATE VOC metal monolith supported catalysts. The metallic catalyst substrates are made of a thin, specialty alloy metal foil called FeCrAlloy. The foil is assembled, flat and corrugated alternating side by side, to form a honeycomb structure. Similar to ceramic monoliths, the assembled foils form cells or parallel channels that allow exhaust gases to run axially through the catalyst. Monoliths are sometimes called flow-through substrates. Exhaust gases flowing through the cells contact the catalyst surface which has been coated onto the cell walls. The advantages of metal monoliths are their high geometric surface area and low pressure drop associated with the thin cell walls. Depending on the application, the foils in metal monoliths can be brazed/welded together, or steam oxidized to provide good mechanical durability and resistance to thermal shock.

Particulate Systems

Applied Catalysts - Model ABATE RCO-EX - Base Metal Extruded Raschig Ring Catalysts for VOC Abatement

Applied Catalysts produces ABATE RCO-EX base metal extruded raschig ring catalysts for VOC abatement. These base metal extrusions have excellent destruction efficiency for a variety of compounds, and thus are a fit for some unique applications. For example, a 5/8” x 5/8” cylindrical version of our extrusions is perfect for RCO applications (Regenerative Catalytic Oxidation) as an RCO Catalyst. Designed with wood panelboard applications in mind, these extrusions have high strength to prevent cracking and fracturing, and fit perfectly onto packed bed heat exchange media designs.

Applied Catalysts - Packed Bed Catalytic Oxidation Spheres

Beads, Spheres, and Pellets are typically used interchangeably, to refer to precious metal impregnated, stabilized alumina, particulate supports. When designing a packed bed system for Industrial Air Pollution Control, Applied Catalysts can provide you with off the shelf solutions in both nominal 1/8”spheres and nominal 1/4” spheres, or a custom sphere size that you may require. Depending on the requirements for destruction, and the VOC’s or compounds that you are trying to abate, we will choose the proper metal loading for that application.

Applied Catalysts - Model RCO - Catalytic Saddles

Regenerative Air Pollution Control Systems are currently the most widely used systems for Industrial Air Pollution Control and VOC abatement. With 95% heat recovery, regenerative systems are very efficient for a wide variety of applications. Catalyst can be used in cases of high flow rate and low concentration of VOC’s to be abated, to lower the operating costs of the regenerative system. Additionally, when CO and NOx are an issue, catalysts can be an excellent option. Catalysts oxidize CO readily, and due to the low temperature required to abate the VOC’s, there is less burner NOx created than with a thermal based system (RTO). Hence, a NOx removal system and capital may be avoided by using ABATE-RCO-S media.

RTO/RCO Media

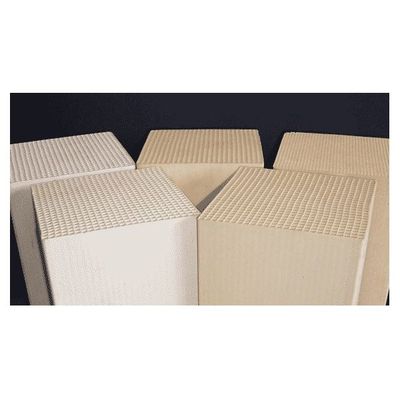

Applied Catalysts - Model RTO - Heat Media - Structured Packing

We supply a wide variety of RTO Ceramic Monolith Heat Exchange Media for structured packing designed RTO’s (Regenerative Thermal Oxidizers). Our MC-01 product is a porcelain ceramic that has the benefits of excellent thermal stability, high resistance to thermal shock, and good thermal mass for effective heat exchange in a compact design. Standard sizes are 150x150mm square block, typically cut to 150 or 300mm. These ceramic blocks come in a variety of cell geometries, including the popular 25×25, 40×40, and 43×43. These products are manufactured by our venture partner, ACIChemshun, in Jiangxi, China. Our facility operates to ISO-9001 quality standards.

Applied Catalysts - Model RTO - Heat Media - Random Packing

Our RTO Ceramic Saddles Heat Exchange Media is for random packing designed RTO’s (Regenerative Thermal Oxidizers). This product is a porcelain ceramic structure that has the benefits of excellent thermal stability and strength. These products are manufactured by our venture partner, ACIChemshun, in Jiangxi, China. Our facility operates to ISO-9001 quality standards.

Applied Catalysts - Regenerative Catalytic Oxidation Catalysts

For Structured Heat Exchange Media designed systems, Applied Ceramics can supply ABATE RCO-M™ Ceramic Monolith catalysts, designed specifically to fit within the RTO/RCO chamber. Whether you are designing a new unit from scratch, or if you are doing a retrofit of an RTO and converting it to an RCO, Applied Catalysts has the right design to match your system.