Applied Chemical Technology (ACT) products

Tanks, Reactors, & Pressure Vessels

ACT - Model ASME - Code Pressure Vessels

Established in 1981, Applied Chemical Technology (ACT) are manufacturers of quality pressure vessels for industries worldwide. ACT assists clients with fabrication of new ASME Section VIII Division I vessels (U Stamp) which are produced in accordance with the requirements of the ASME Boiler and Pressure Vessel Code. We also repair or alter pressure vessels (R Stamp) to meet the requirements of ASME Boiler and Pressure Vessel Code. The ACT team of engineers and craftsmen are equipped to carry out projects from conception, through design, fabrication, and installation. Our clients include some of the world’s most respected names in industry. All of our projects, including ASME designs, are done under the strictest confidentiality.

ACT - Custom Piping

Applied Chemical Technology specializes in the design and construction of chemical production and processing plants. Our service portfolio includes turnkey engineering, development, manufacturing, and installation of standard and custom process systems. As part of our fabrication capabilities for process systems, we produce custom piping for tanks, reactors, and pressure vessels. Our ability to design and manufacture custom piping for chemical processing allows us to tailor the system to the specific needs of the facility.

ACT - Mixing Tanks

Applied Chemical Technology specializes in the design and construction of chemical production and processing plants. Our service portfolio includes turnkey engineering, development, manufacturing, and installation of standard and custom process systems. We fabricate numerous types of tanks and pressure vessels for chemical process systems, including mixing tanks.

Fluid Bed Systems

ACT - Batch Fluid Bed Systems

Fluidized Beds for Granulating, Coating, Thermal Processing, and Reacting. Since 1981, Applied Chemical Technology (ACT) has designed and fabricated state-of-the-art batch fluid bed systems. Through the years, our technology has changed with current breakthroughs to provide fluidized beds used for coating, agglomerating, granulating, drying, classifying and more. ACT builds batch fluid beds beginning at a 5 liter bowl capacity. Our standard models may include explosion protection and solvent recovery, and all models can be further customized as needed.

ACT - Specialized Fluid Beds

At ACT we understand that one size does not fit all. That’s why all of our fluid beds can be modified to suit your specific needs. Where necessary, we build your fluid bed from specialty materials ranging from food and pharmaceutical grade stainless steel to high temperature Inconel 600 or other specialty alloys. We are a certified ASME Code Shop – whatever you need, we can build.

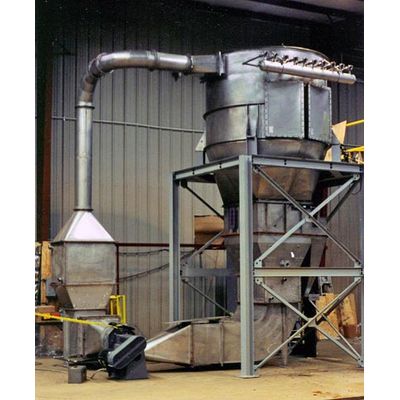

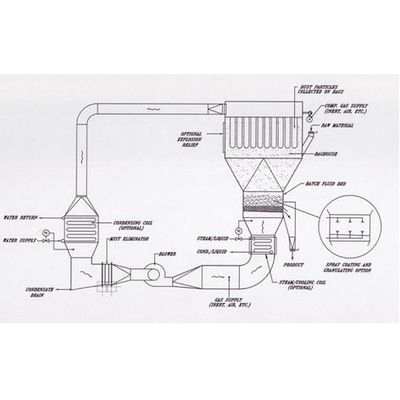

ACT - Combination Fluid Bed Baghouses

Fluidized Beds with Built-In Baghouses Designed for Small Footprints. Applied Chemical Technology’s (ACT) Combination Fluid Bed/Baghouses integrate process operations and environmental control into a single unit, reducing space requirements and allowing greater flexibility in plant layout. The continuous operation design offers non-stop production capabilities for a wide range of process applications, while the integrated baghouse easily captures undersized particles for elimination or recirculation. We offer a versatile range of fluid bed sizes to meet any need, from research and development operations to full-scale production plants.

Turn Key Systems

ACT - Model 3-10TPH - Continuous Coating Plant

An ACT Continuous Coating System may be used to apply one or more coating materials and/or layers to a suitable substrate. An ACT Continuous Coating System is proven to produce high quality coated products for slow release, controlled release, moisture barrier, dust suppression, and other desirable product qualities. A license agreement for a proven coating material is available. ACT will also work with our client to optimize coatings for a specific product or to develop a coating process for alternative coatings using ACT’s coating system.

Rotary Drums

ACT - Conditioning Rotary Drums

At Applied Chemical Technology (ACT), we build rotary drums used in the conditioning of solid materials like fertilizer, phosphate rock, or tar sands. Whether you need to reduce tackiness or dustiness, our rotary conditioning drums are built with quality and safety in mind. Our team of engineers, designers, and craftsmen to size and design the right drum for your specific needs.