Askon Engineering Ltd. products

Filling and Packaging - Form-Fill-Seal Tubular Machine

Askon - Tubular Form-Fill-Seal Bagging Machine

The FFS machine is an automatic packaging machine that forms, fills and seals bulk product in PE bags. First step of process is bag forming which includes tubular foil unwinding and bottom seal. Next processes are bag filling and bag closure. The machine allows high productivity - up to 8 t / h. It is suitable for bags in the range of 10-30 kg.

Filling and Packaging

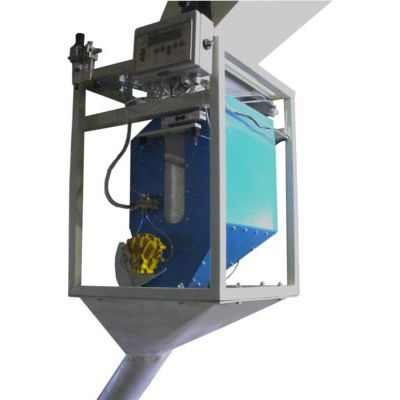

Askon - Valve Filling Machine

Valve filling module is suitable for powder materials, as well as granulated products without frangible requirements. Machine handles valve bag range 10 - 50 kg. The basic machine model operates without automatic bag feeder. Complete process automation can be assured with an automatic bag feeder that places a bag on the filling spout. Auger dosing is used. Valve filling machine assures very good compaction of the material during filling. Fast filling speed can be reached.

Open Mouth Filling Machine

The open bag filling module is used for packaging both powder or granular materials. The advantages of the filling machine is the possibility of using different types of bags – paper, polyethylene or polypropylene. ?ccording to the type of bag material, closure will be sewing or sealing. The size of the bags varies from 5-30 kg. The options for the filling installation are semi-automatic or automatic. In first option an operator is required, who will take the bag out and put it on the closure station. The automatic option is suitable for higher production workload. They have high measurement accuracy. The machine performs 3-4 cycles/min to fill a bag.

Palletizing

Askon - Strech Wrapping Machine

Ascon Engineering offers a stretching wrapping machine for wrapping palletized loads with polyethylene film foil (boxes, bags, etc.). The machine is available in automatic and semi-automatic variants and it capacity can reach up to 20 pallets/hour. It works with foil that has thickness ranged 0.10μm ÷ up to 0.25μm.

Grain Processing

Askon - Automatic Scale

Askon Engineering offers automatic scales for portion measurment and monitoring of powder or granulated product flow. Production capacity of the scales ranges from 2t/h to 60 t/h. Modern technology provides high accuracy and precision in measurements. Steady and durable design of the machine reduces vibration leading to higher accuracy of the measurements. Minimal product contamination is ensured by minimizing the possibility of dust penatration into the scale - dust zones are compact and few in number.

Askon - Moisture Control Machine

The moisture control system has high accuracy of moisture measurement. The capacitive sensor detects the moisture in the grain, thanks to which the system regulates it in a controlled way. Depending on the degree of moisture in the grain, the set targer moisture and the flow rate of the passed material, the system realizes continuous calculation of the water volume that needs to be added to the product. Proper moistening is one of the conditions for successful and efficient grinding. The moisture control system has a robust and compact design combined with easy maintenance.

Dosing

Askon - Belt Dosing Weigher

This dosing method is suitable for bulk materials that have high requirements for product preservation.

Conveying

Askon - Roller Conveyor

Roller conveyors can vary in width and length according to production needs.