- Home

- Companies

- Astec, Inc.

- Products

Astec, Inc. products

Complete Systems

Nomad - Portable Asphalt Plants

Intended for portability, durability, and reliability, Nomad plants meet the demands of a variety of small, medium and large projects that require quality hot mix asphalt. Nomad plants are designed and built in the U.S.A. with proven results around the globe. You can depend on your Nomad plant to produce high-quality hot mix asphalt for years to come with a minimum of upkeep.

Astec - Soil Remediation Plants

Astec, Inc. produces innovative infrastructure equipment used around the globe with product lines including; thermal remediation equipment, recycling equipment and renewable energy systems.

Astec - Frac Pack Sand Drying Plants

Astec created the industry’s first, full, single-source dry plant for the proppant (frac. sand) and other sand processing industries. This rugged plant is engineered from the ground up to withstand non-stop operation, 24 hours per day, 7 days per week, 365 days per year, year after year. As the United States’ largest manufacturer of asphalt plant equipment, Astec has built its reputation as the most resilient drying, storage systems, and controls, with world renowned service. Our high-frequency screens are the toughest, most versatile, and most efficient available. After you are up and running our service and parts team will be available to ensure a finely tuned plant.

Plant Components - Material Feed

Astec - Cold Feed Systems

Astec cold feed and recycle units are built to give many years of service in demanding environments. All parts of Astec bins, from the bins themselves to the steel bulkheads and foundations, are fabricated to perform and stand up to front-end loaders and abrasive materials year after year.

Plant Components - Drying / Mixing

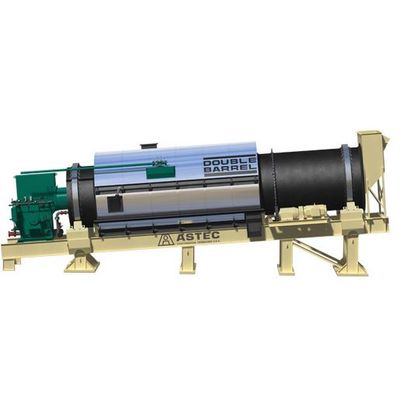

Astec - Double Barrel Dryer/Drum Mixer

Astec brings you the Double Barrel dryer/drum mixer, the mixer of choice over any other. The Double Barrel dryer/drum mixer combines the latest in hot and warm mix technology with other great Astec features. Get guaranteed productivity and top quality mixes, while keeping operating costs per ton of mix low and meeting the most stringent environmental codes. Relocatable and portable versions all perform to the same high standards.

Plant Components - Liquid Additives

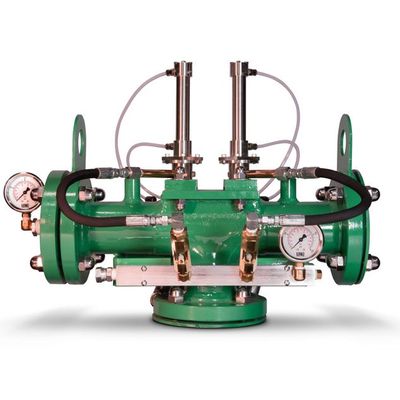

Astec - Warm Mix Systems

The benefits of warm mix asphalt, such as reduced energy consumption, lowered emissions, and elimination of visible smoke, are well-known in the asphalt paving industry. Warm mix technology allows mix to be prepared and placed at lower temperatures than conventional hot mix. To achieve this, the viscosity of the liquid asphalt cement (AC) must remain low at the reduced temperatures. Maintaining a low viscosity at lower temperatures allows mix to flow freely through storage, transfer, and placement equipment and is more easily compacted.

Plant Components - Emission Control

Astec - Portable Pulse Jet Baghouses

The Astec portable baghouse is designed as an integral component of the Six Pack® portable hot mix facility. Built-in running gear, high-rise air bag suspension and optional retractable plate foundations eliminate setup hassles. Portable baghouses are available in a range of capacities.

Astec - Reverse Pulse Baghouses

Reverse Pulse Baghouses for Hot Mix Asphalt Facilities. With ever increasing specifications, dust handling has become a critical component in all asphalt plant operations. With that in mind, Astec offers the Reverse Pulse™ baghouse. Modular in design, the Reverse Pulse baghouse can be fitted to your exact size requirements. The Reverse Pulse baghouse is available in a range of sizes from 5,000 to over 100,000 ACFM. It is a ruggedly constructed system; manufactured out of 3/16” corrosion resistant steel plating.

Plant Components - Material Load-Out

Astec - Long-Term Storage Silos for Asphalt Facilities

Astec silos store mix for four days† without loss of mix quality. That’s true storage. And we guarantee it in writing.