Atex Certified, by MM Group products

Atex - EX HID Signo RFID Reader for Hazardous Areas

The EX HID Signo RFID Reader, designed by Wath Group Ltd, is part of the SX product family, developed specifically for use in potentially explosive environments. This reliable reader is compatible with various access control systems, offering robust integration capabilities. It supports multiple frequencies: HID multiCLASS 13.56 MHz, LF 125 kHz, and BLE 2.4GHz. Its construction involves machined stainless steel with `mb` reinforced and `eb` encapsulated encapsulation, ensuring durability. The device features a tempered glass inspection window allowing visual indication of access verification through a configurable LED. Suitable for use in explosion hazard zones 1, 2, 21, and 22, it reads passive transponder tags to manage access restrictions effectively. Users must supply appropriate cables and Ex cable glands to suit the installation environment.

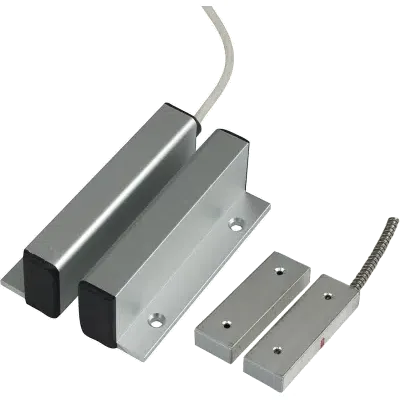

Atex - Magnetic Proximity Sensor for Hazardous Areas

The Magnetic Proximity Sensor is designed for use in hazardous areas, featuring a robust construction that adheres to certification standards such as II 1G Ex ia IIC T6 - T4 Ga and II 1D Ex ia IIIC T 125°C Da. The sensor is crucial for detecting unauthorized entry in protected zones, thus acting as a security device in ATEX zones. To ensure an Ex compliant installation, it requires a certified isolation amplifier for both power supply and signal transmission. This sensor is particularly valuable in environments where reliable security measures are critical, ensuring safe and efficient operations. Known for its precision in reporting unauthorized access, it extends its application across various industrial sectors that demand stringent safety and security protocols.

Atex - Intrinsically Safe Optical Sensors for Hazardous Areas

Intrinsically safe optical sensors are designed to be utilized in environments where there is a risk of explosion, such as in the mining, gas, and petrochemical industries. These sensors are built to detect the level of both aqueous and non-aqueous liquids, including thinners, oils, and paints. They are powered using a NAMUR current loop in a two-wire configuration and include LED signals to indicate status. The sensors are encased in IP65 or IP68-rated housing, offering protection against dust and water ingress, and they can operate within a temperature range of -30°C to 80°C. They withstand pressures up to 3 Mpa and use materials such as 17 246 stainless steel and food-grade stainless steel for construction. The electrical connections are facilitated through terminal blocks or cables. These sensors carry ATEX certification for use in explosive atmospheres (II 1/2G Ex ia IIC T6 Ga/Gb), ensuring their suitability and safety for sensitive applications.

Albeo - Intrinsically Safe Power Adapters

Intrinsically safe power adapters are critical components designed to provide power to electronic devices in explosion-prone environments while adhering to stringent safety norms. Specific standards, such as PN-EN 60079-0 and 60079-11, guide their design to ensure the power circuits are galvanically isolated from potentially hazardous origins. These adapters are suited for establishing safe connections between zones with explosion risks and secure zones. It is essential that they limit energy at the interface to prevent hazardous conditions. Each device's maximum allowable energy is defined in its intrinsic safety certification, such as ATEX. Incorrect usage involves connecting uncertified output circuits directly to certified systems, necessitating solutions like insulators or Zener barriers. Models like the MM 2012 EX and MM 3012-800 provide 12V outputs with certified isolation.

Atex Certified - MMG Intrinsically Safe PIR+MW Detector

The XD10TTAM/Ex Detector (MM 1007 Ex) is a combined detector consisting of three detection technologies. It uses two PIR sensors and one microwave detector. The range of the microwave detector is adjustable from 0 m to 15 m, while the PIR range is fixed at 10 m. The detection range can be adjusted by changing the microwave detection range.