Augusta Fiberglass (AFC) products

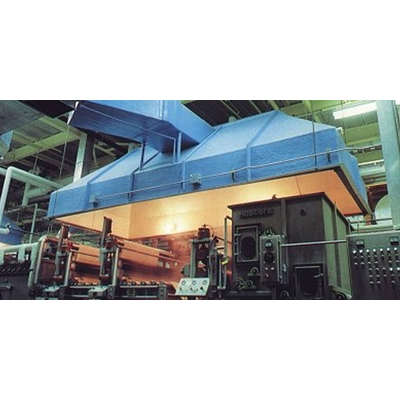

AFC - Fiber-Reinforced Plastic (FRP) Pipe, Duct & Hood

Augusta Fiberglass engineers and manufactures custom-made pipe for a variety of applications. Typically engineered with safety factors of 10:1 against pressure and 5:1 against vacuum, AFC’s pipe surpasses the performance of commodity piping systems at a comparable and often lower cost.

AFC - Custom Stacks & Stack Liners

Augusta Fiberglass engineers and manufacturers fiberglass chimneys, stacks and stack liners that are either free standing or supported. We have the experience to design virtually any size necessary to accommodate the exhaust stream from almost any process.

AFC - Fiber-Reinforced Plastic (FRP) Process Vessel

Augusta Fiberglass engineers and manufactures FRP process equipment and scrubbers in a wide range of shapes, sizes and configurations. While the majority of these vessels are cylindrical, AFC can supply other shapes to meet the exacting demands of our customers.

AFC - Industrial & Commercial Fiber-Reinforced Plastic Tanks (FRP)

Augusta Fiberglass engineers and manufactures FRP (Fiber-Reinforced Plastic) Tanks in a wide range of shapes, sizes and configurations. While the majority of these tanks are cylindrical, AFC can supply rectangular or other custom shapes to meet the exacting demands of our customers.

AFC - Chemical Storage Tanks

Augusta Fiberglass Coatings, Inc. designs, engineers, and manufactures custom fiberglass chemical storage tanks, FRP (fiberglass-reinforced plastic) chemical holding tanks, and FRP process equipment for the chemical processing industry. As the leading chemical tank manufacturer, we combine technical expertise with on-the-job knowledge and experience. Augusta Fiberglass has maintained the ASME RTP-1 Accreditation since 1995.

AFC - Custom Fabricated Tank for Wastewater Treatment

The products shown here were custom molded for use as fluid transmission components in a waste water treatment plant. The customer required components with piping thicknesses that would be suitable for ±16″ WC, and durable enough for years of maintenance free use. With this information as well as the rest of the supplied specifications we fully engineered all of the components as well as material selection.