- Home

- Companies

- Avient Corporation

- Products

Avient Corporation products

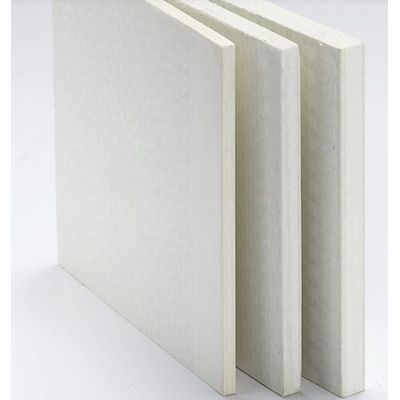

Advanced Composites - Continuous Fiber Composite Panels

Avient CRTM - Composite Sandwich Panels

CRTM™ (continuous resin transfer molding) panels are thermoset composite sandwich panels with tailored, multi-axial fiber reinforcements, high-fiber volume and very low void content. These custom-engineered products are available with a wide variety of core materials, including end-grain balsa, foam or engineered woods and laminate face-sheets with continuous fiberglass and/or carbon fiber reinforced polyester, vinyl ester and epoxy or custom resins. Panels are custom engineered to meet customer needs by varying core thicknesses to affect stiffness, core materials to affect weight, fiber to modify the stiffness-weight ratio, and resin material to affect strength.

Avient GlasArmor - Ballistic Resistant Panels

GlasArmor™ Ballistic Resistant Panels are constructed to provide any facility with military grade protection. Originally developed for use by the Department of Defense for protection from mortar fire, our fiber reinforced polymer (FRP) composite panels offer superior ballistic resistance at less than 25 percent the weight of a comparable steel panel.

Avient Hammerhead - Marine Composite Panels

Hammerhead™ Marine Composite Panels, made from thermoplastic continuous glass fiber-reinforced face sheets and polyester foam core, are engineered to provide simplified installation, long-lasting components, and overall cost reduction for boat manufacturers. These versatile panels can be used in a variety of boat building applications including: interior bulkheads, decking, ceilings, hatches, covers, cabinetry and fittings. The exceptional strength-to-weight ratio provides lightweight yet strong structural performance for increased payloads. And they are resistant to ultraviolet (UV) light, chemicals, moisture degradation, and rot to withstand harsh marine conditions.

Avient Polystrand - Thermoplastic Composite Panels

Constructed of Polystrand™ continuous fiber reinforced thermoplastic facesheets thermally bonded with a variety of internal core materials including thermoplastic foam and honeycomb core, these engineered composite panels are constructed without secondary adhesives for a stronger bond and more efficient manufacturing process. These panels are designed and customized to maximize performance and minimize weight. By configuring facesheet layers, thicknesses, and fiber content in combination with the right core material selection, we can help you achieve your specific design and performance requirements.