Babcock Wanson - CNIM Group products

Industrial Process Air Heaters

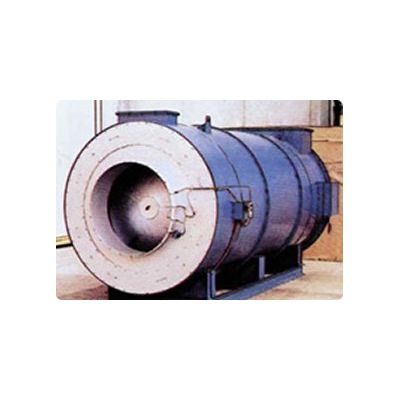

Babcock Wanson - Model HTV-N - Indirect Process Air Heater

Constructed from carbon or stainless steel to the highest specification, HTV-N Indirect Process Air Heaters provide clean hot air at up to 350°C. The heaters can be fitted with inspection and cleaning doors, condensate drains and water-resistant gaskets where the process demands and utilise specialist welding procedures to reduce the risk of particulate deposits on the heating surface.

Thermal Oxidation Plants

DCT - Regenerative Thermal Oxidation Plant

The Regenerative thermal oxidation allows solvent oxidation by increasing the polluted air temperature over 750-800 °C with a high efficiency heat recovery system using ceramic material.Starting from 1995 till today, Donau Carbon Technologies Srl, with more than 100 combustors of this type having capacities between 5.000 and 200.000 Nm3/h, achieved very high quality and reliability levels. Therefore actually Donau Carbon’s products represent the State of the Art.Donau Carbon Technologies Srl fulfils markets requirements by offering regenerative combustors also for particular applications, like treatment of CO streams produced by industrial processes, treatment of odors and treatment of flue gases coming from waste processing.

DCT - Recuperative Thermal Oxidation Plant

The recuperative thermal oxidation allows the air depuration by thermal oxidation at 750-800°C. The thermal recovery is done by means of an air-air heat exchanger.

DCT - Catalytic Thermal Oxidation (CTO)

Catalytic oxidation is a process to treat waste air or gases. Usually traditional oxidation processes are running at temperatures higher than 750°C. In case a few organic compounds are present in the gas stream, to keep these temperatures, the incineration process needs a high quantity of additional fuel. With the catalytic oxidation the additional fuel can be saved by means of a special catalyst that makes possible the oxidation of organic compounds at lower temperatures (for example from 250 to 350).

Thermal Oxidisers

Babcock Wanson - Recuperative Oxidisers

Regenerative Oxidisers are used where there is no requirement for heat recovery, or the amount of heat that can be recovered is too small to justify a Thermal Recovery Oxidiser. They are also well suited to processes that discharge high volumes of exhaust with relatively low VOC content.

Air Treatment Plants

DCT - Air Treatment Plant

Donau Carbon Technologies Srl designs and supplies complete lines for the treatment of dust and gases polluted flows. The main installations have been done for the treatment of flue gases coming from industrial process, therefore characterized by high concentration of specific pollutants.For example, Donau Carbon Technologies Srl realized plants for the treatment of flue gas produced during processing of materials for telecommunications, able, therefore, to capture very light dusts and strongly acid vapors.

Water Treatment Solutions

Softening

Is the minimum basic treatment, which converts by circulation through resins, the calcium and the magnesium carbonates which produce scaling of the wetted surfaces. These salts are exchanged for the soluble sodium carbonates by contact with the resin. Softener units are presented in the form of vessels containing the resin, which is periodically regenerated using a sodium chloride solution. This type of water treatment alone is not always sufficient for industrial applications as dissolved gases, carbonates, silica and the other ions pass through these resins which can be additional sources of corrosion, fouling, foaming or steam carry-over. In that case, additional treatments (decarbonisation and demineralisation) are needed.

Process and Space Air Heaters

Process Air Heaters

BABCOCK WANSON offers the products and associated services you need for industrial drying applications. Principle: Fresh air is drawn into the generator by an external fan. This air is heated by contact with the combustion chamber and the second pass tubes to reach the desired temperature. Applications: for medium and high temperature air requirements. Industries: Plant drying, Food processing, Ceramics, Pharmaceuticals, Sugar refining, Milk drying, Print drying, Laminate curing, etc.

Other Products

DCT - Model X-CSR - Printing Ecosystem and Aims Plant

DCT`s innovative plant, X-CSR, is adressed to the printing ecosystem, and aims to extend solvent technology, generally adopted only by big companies, to SMEs that are using smaller quantities.

DCT - Solvent Recovery Plant with Water Adsorption

This process uses water to recover high-boiling, totally soluble, solvents (ex. DMF). Mainly it is employed in the synthetic leather, textile and elastic fabrics, on polyurethane basis, production fields.