Bachmann Dampjoint Inc. products

Dampers

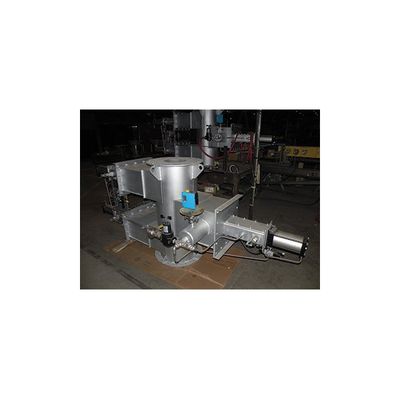

Bachmann - Speciality / Custom Gas Flow Dampers

On numerous occasions, Bachmann Dampjoint has custom designed and manufactured specialty dampers that are outside of the conventional damper categories. Keeping the exact requirements of the client in mind, Bachmann Dampjoint has designed the appropriate equipment to meet the special needs of every client.

Bachmann - Offset Disk Dampers

Also known as 3-lever valves, the offset disc damper is used where the degree of tight shut-off required cannot be achieved with a butterfly damper, and where a guillotine damper is not practical.

Bachmann - Dual Seal Dual Skin (DSDS) & Double Louver

Our DSDS design is the best technical and commercial fit for isolation applications where the damper is normally open, and reliability is a concern. The innovative DSDS design is our cost-effective dual-louver solution that is transforming the isolation damper market, specifically in applications where the damper is normally open. It’s no surprise that we have more experience designing,manufacturing and assembling DSDS dampers than all of our competitors combined!

Bachmann - Louver and Butterfly Dampers

Bachmann Dampjoint designs and manufactures a multitude of different types of gas-flow dampers in all sizes and configurations. Usually found in heavy utility and industrial plants, Bachmann Dampjoint gas flow dampers, with many cost-effective innovations, are used for isolation, flow control or a combination of both. The blades are actuated by pneumatic, electro-mechanical, hydraulic, or manual drive systems.

Flex-Seal - Guillotine Solid - Flex & Convolution Seal

The “Flex-Seal” guillotine damper consists of a body, blade, and bonnet. The seat is a convex track covered with a high nickel-alloy cap seal, providing a corrosion and stick-resistant flexible surface. When tight shut-off is paramount, a guillotine is often specified to do the task. However, there are many different designs and the selection of the proper type of guillotine damper depends on the application and can vary greatly. Bachmann Dampjoint can guide the end user to select the most cost-effective solution between:

Expansion Joints

Metallic Expansion Joints

Bachmann Dampjoint manufactures high performance expansion joints in such materials as stainless steel, nickel, inconel, incoloy, hastelloy, titanium, monel, and other sophisticated alloys.

High Temperature Non-Metallic Expansion Joints

High-temperature non-metallic expansion joints are used primarily in flue and duct systems, and depending upon the specific operating conditions, are built up of a number of insulating thermal fabric layers with an external fluoroplastic cover. These materials can withstand up to 2300º F. These composite joints are usually located where low spring rates are combined with large axial and lateral movements. These expansion joints are very economical to use and can be adapted to unique, limited space situations.