- Home

- Companies

- Baolan EP Inc.

- Products

Baolan EP Inc. products

VOCs Series

Baolan - Regenerative Thermal Oxidizer (RTO)

Regenerative Thermal Oxidizer (RTO) uses the ceramic regenerators to store the heat generated by the decomposition of VOCs, and uses the thermal energy stored in the ceramic regenerator to pre-heat and decompose the untreated VOCs, thereby achieving high thermal efficiency.

Baolan - Model SRCO - Regenerative Catalytic Oxidizer

Resolved safety issues. Only 200-400 can be used to catalyze the decomposition of almost all organic matters, avoiding the potential fire safety hazards faced by conventional TO, RTO, RCO incineration.

Baolan - Zeolite Rotor

The zeolite rotor is to condense high-volume and low-concentration exhaust gas to high-concentration and small-volume exhaust gas, thereby reducing the equipment investment and operating cost, and improving the efficient treatment of voc exhaust gas. When dealing with the combustion and recovery of high-volume, low-concentration exhaust gas, if there is no zeolite rotor and the combustion is performed directly, the exhaust gas treatment equipment will not only be bulky, but also the operating costs will be huge.

Baolan - Fixed-Bed Molecular Sieve Adsorption Desorption System

Molecular sieve adsorption-desorption refers to the use of solid molecular sieve (molecular sieve currently includes: activated carbon molecular sieve and zeolite molecular sieve), adsorption of pollutants in industrial waste gas, according to different components of waste gas, select the appropriate molecular sieve. When the molecular sieve is saturated, the pollutants will be desorbed. The catalytic combustion technology is used to oxidize the organics in the industrial waste gas into carbon dioxide and water, so as to achieve the purpose of purification.

DeSOx - DeNOx - Emission Control System

Baolan - Model DeSOx - Selective Catalytic Reduction System (SCR)

SCR (Selective Catalytic Reduction) is a selective catalytic reduction technology. At present, ammonia catalytic reduction method is the most widely used technology. It has no by-products, no secondary pollution, simple device structure, high removal efficiency (up to 90%), reliable operation, and easy maintenance. Selectivity means that in the presence of oxygen and in the presence of oxygen, NH3 preferentially undergoes a reduction and removal reaction with NOx to form nitrogen and water, without oxidizing with the oxygen in the flue gas.

Baolan - Model DeNOx - Selective Non-Catalytic Reduction System (SNCR)

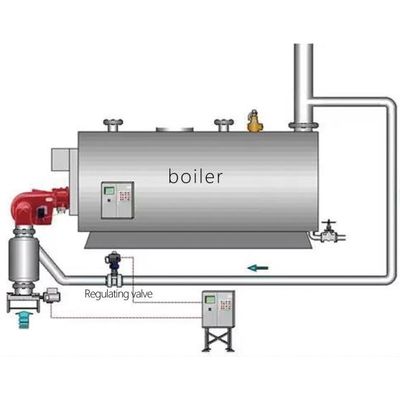

SNCR (Selective Non-Catalytic Reduction) is a selective non-catalytic reduction method. It is an economical and practical NOx removal technology. Its principle is based on NH3, urea [CO (NH2) 2], etc. Before the boiler is atomized or injected into the boiler, it is atomized by the heat in the furnace. Sprayed into the furnace temperature range of 800 ? ~ 1100 ?, the reducing agent quickly thermally decomposed into NH3 and other by-products, and then NHCR and NOx in the flue gas undergo SNCR reaction to generate N2. It can therefore be considered a selective chemical process. The reducing agent has different reaction temperature ranges. This temperature range is called a temperature window, which has a great influence on the denitration efficiency of the method.

Baolan - Denitration by Oxidation System

Denitration By Oxidation mainly uses oxidants such as ozone, hydrogen peroxide or sodium hypochlorite to oxidize insoluble low-value nitrogen oxides to soluble high-value nitrogen oxides, and then absorb the nitrogen oxides with alkaline solution in the washing tower to reach Purpose of denitration. The denitration system can remove NOx, sulfur dioxide, and particulate matter in the flue gas at the same time under different concentrations and proportions of pollutants such as NOx, without affecting other pollutant control technologies. It is one of the traditional denitration technologies. Efficient complementary or alternative technologies.

Baolan - Active Coke System

Baolan - Low Nitrogen Oxide Combustion System

Low nitrogen oxide combustion technology is to improve the combustion equipment or control the combustion conditions, using a variety of combustion means in the furnace to control the production of NOx in the combustion process, in order to reduce the NOx in the tail gas of the combustion technology.

Baolan - Bag Dust Filter

Bag filter is generally referred to as a bag filter, which is a dry dust filter device. It is suitable for trapping fine, dry, non-fibrous dust. The filter bag is made of woven filter cloth or non-woven felt, and the dust-containing gas is filtered by the filtering effect of the fiber fabric. When the dust-containing gas enters the bag filter, the dust with large particles and specific gravity is affected by gravity Settle down and fall into the ash hopper. When the gas containing the finer dust passes through the filter material, the dust is trapped and the gas is purified.