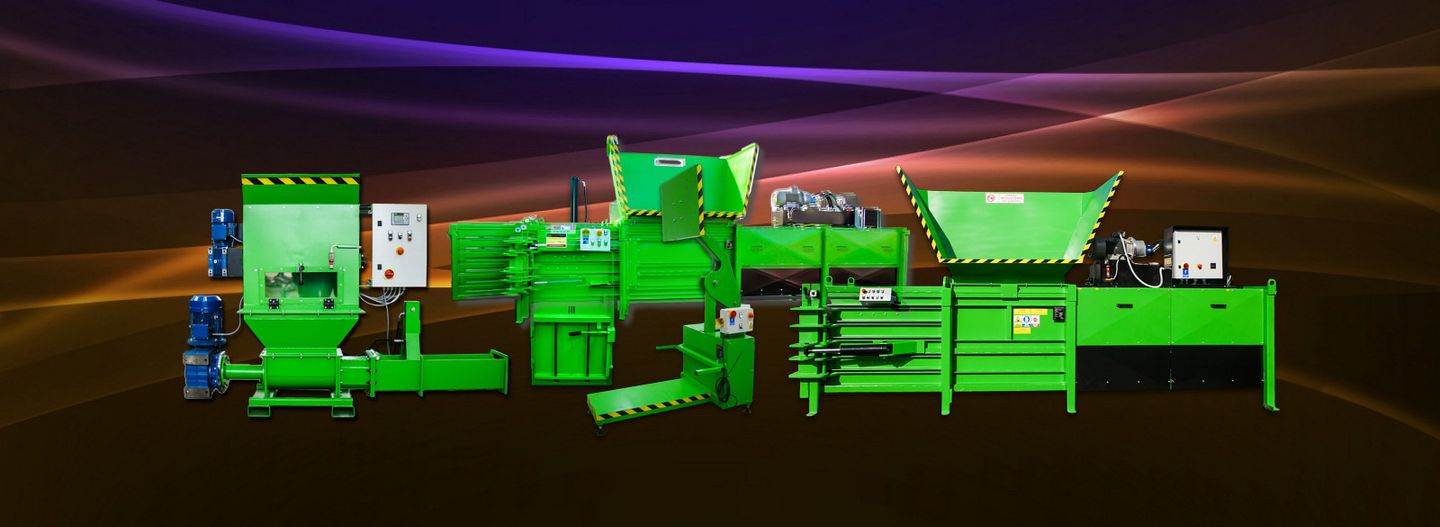

Bartontech Rafal Barton products

Vertical Balers

Bartontech - Vertical Baler

Vertical baler BARTONTECH 50 Plus with 4 tonne pressure is a simple and efficient device for compacting waste paper and other recyclable materials. Excellent for wholesalers, stores, hotels and wherever selective waste management is carried out. It’s a certified Polish product, very cheap in operation.

Bartontech - Double Chamber Vertical Baler Press

Technical parameters: unit height: 2950 mm. machine weight: 2530 kg. hopper width: 800 mm. height of hopper opening: 1200 mm. motor power: 5.5 kW. power supply: 3 x 400 V/50 Hz. circuit breakers: 25 A, delayed. cable connector: CEE 5 x 32 A/6H. unit depth: 1420 mm. compartment length: 1180 mm. chamber width: 800 mm. bale dimensions: 1200 x 800 x 800 mm. bale binding: Manual. bale ejection: Semi-automatic. bale weight: 250 – 450 kg. working cycle time: 50 s. pressure force of hydraulic cylinders: 250 kN (25 t). machine length: 2715 mm. width of machine: 1405 mm.

Horizontal Balers

Bartontech - Semi-Automatic Baler and Horizontal Press

Semi-automatic baler horizontal press 400 Plus is suitable for processing the material to an average of 1 ton per hour. The machine is ideal for industrial plants producing high quality material in the relative small amounts. When the disc presses projecting entirely to the door 400 Plus press produces a very compact bales with dimensions and weight comply with the requirements of the mill. Bale can be completely discharged from the chamber after binding, facilitating switching between materials. Vertical binding system makes the machine is easy to use, quick to bind and suitable for setting along the wall.

Bartontech - Semi-Automatic Baler and Horizontal Press

Semi-automatic baler, horizontal press 600 Plus provides a throughput of 1,5 tons per hours which makes it perfect for waste processing plants. The machine has a crushing force of 50 tons, the knife cutting off the excessive material in the charging chamber, the floor made of wear-resistant steel, a bale full indicator and a three-phase motor with the power of 15 kW. Optionally, the baler may be equipped with additional devices, e.g.: a tippler for 1000 L containers, cooperating conveyor belt, extra security devices, etc. Horizontal binding system makes it perfect for baling plastic PET bottles and aluminum cans. The whole process of baling, apart from binding, takes place in an automatic cycle.

Bartontech - Semi-Automatic Baler and Horizontal Press

Semi-automatic baler, horizontal press 600 MAX provides a throughput of 1,5 tons per hours which makes it perfect for waste processing plants. The machine has a crushing force of 50 tons, the knife cutting off the excessive material in the charging chamber, the floor made of wear-resistant steel, a bale full indicator and a three-phase motor with the power of 15 kW. Optionally, the baler may be equipped with additional devices, e.g.: a tippler for 1000 L containers, co-operating conveyor belt, extra security devices, etc. Horizontal binding system makes it perfect for baling plastic PET bottles and aluminum cans. The whole process of baling, apart from binding, takes place in an automatic cycle. The main feature of 600 MAX baler is the possibility of ejecting a single bale due to the use of elongated actuator.

Bartontech - Semi-Automatic Baler and Horizontal Press

Semi-automatic baler, horizontal press with press flaps model 600 Cross dedicated to foam, tyres and other recyclable materials. Excellent baler in tyre recycling process – pyrolysis. The machine is also able to bale waste like paper, cardboard etc.

Bartontech - Semi-Automatic Baler and Horizontal Press

Semi-automatic baler, horizontal press 800 Plus provides a throughput of 2 tons per hours which makes it perfect for waste processing plants. The machine has a crushing force of 75 tons, the knife cutting off the excessive material in the charging chamber, the floor made of wear-resistant steel, a bale full indicator and a three-phase motor with the power of 15 kW. Optionally, the baler may be equipped with additional devices, e.g.: a tippler for 1000 L containers, co-operating conveyor belt, extra security devices, etc. Horizontal binding system makes it perfect for baling plastic PET bottles and aluminum cans. The whole process of baling, apart from binding, takes place in an automatic cycle.

Bartontech - Semi-Automatic Baler and Horizontal Press

Semi-automatic baler, horizontal press 800 MAX provides a throughput of 2 tons per hours which makes it perfect for waste processing plants. The machine has a crushing force of 75 tons, the knife cutting off the excessive material in the charging chamber, the floor made of wear-resistant steel, a bale full indicator and a three-phase motor with the power of 15 kW. Optionally, the baler may be equipped with additional devices, e.g.: a tippler for 1000 L containers, co-operating conveyor belt, extra security devices, etc. Horizontal binding system makes it perfect for baling plastic PET bottles and aluminum cans. The whole process of baling, apart from binding, takes place in an automatic cycle. The main feature of 800 MAX baler is the possibility of ejecting a single bale due to the use of elongated actuator.

Bartontech - Semi-Automatic Baler and Horizontal Press

Semi-automatic baler, horizontal press with press flaps model 800 Cross is dedicated to foam, tyres and other recyclable materials. Excellent baler in tyre recycling process – pyrolysis. The machine is also able to bale waste like paper, cardboard etc. The main feature of 800 Cross baler is the possibility of ejecting a single bale due to the use of elongated actuator.

Bartontech - Semi-Automatic Baler and Horizontal Channel Press

Baler, channel press 800 Schort is suitable for an average material throughput of up to 2 tons per hour. The machine is ideal for industrial plants producing high-quality material in relatively small quantities. With the plate of the press extending completely into the door, the press 800 produces very compact bales with dimensions and weights in accordance with the requirements of paper mills. The vertical tying system makes the machine easy to use, quick to bind and suitable for positioning along the wall.