- Home

- Companies

- BDP Industries

- Products

BDP Industries products

Thickening

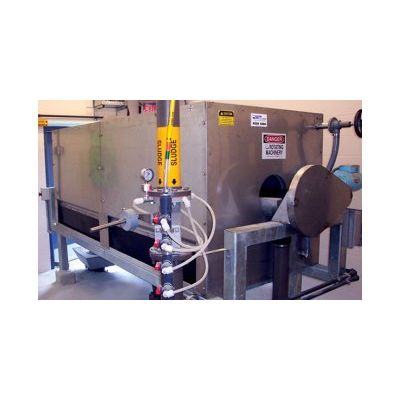

Rotary Drum Thickener

Unique design provides a viable option to a Gravity Belt Thickener with the following advantages: a smaller footprint, unattended operation, lower investment, and maintenance costs. Performance is similar.

Model GBT - Gravity Belt Thickener

The GBT™ is used to thicken primary or secondary sludge prior to centrifuge or digestion processes. High unit capacity per floor space

Dewatering

Model 2VP - Belt Press

Better Accessibility and Performance with LOWER Installation and Maintenance Costs. The unique layout of the Model 2VP provides for easier access for operators and maintenance staff. The durable construction will provide years of reliable service.

Sahara - Belt Press

Paddle wheel feed distributor provides uniform distribution of highly viscous feed slurries.

Model E - Belt Press

The model E has an independent gravity zone like the 3DP but is for less demanding applications because it’s pneumatic versus hydraulic and 7 rolls versus 8 pressure zone.

Model DSP - Screw Press

BDP developed this screw press specifically for Biosolids dewatering to provide high capacity, excellent solids capture, in a fully enclosed system with automated simple operation.

Model HO - Twin Wire Belt Press

Invented primarily for the Pulp and Paper Industry with the capability to combine: “Wedge roll”, “S roll” or “Nip roll” in a custom configured unit to provide very high compressive: time and pressure for maximizing discharge solids and capacity as required by the client’s specific needs.

Model DDP - Belt Press

Providing high performance and flexibility, the Model DDP was developed with the smaller size waste-water treatment plant in mind.

Model 3DP - Belt Press

Designed with unique features to provide higher discharge cake solids at higher feed flow rates. The 3DP is a rugged, durable machine that will provide years of reliable service.