Beijing Hyperfore Technology Co.,Ltd. products

Pigging Systems

Hyperfore - Sanitary or Hygienic Pigging Systems

As can be seen,Hyperfore sanitary pigging system is composed of a launching station, a receiving station and a pig. Obviously, It can improve production, reduce waste and cross contamination. Particularly, it is suitable for the recovery and utilization of dairy , alcohol, liquid drugs, cosmetics, cleaning agents, sauces, lithium battery slurry, paint coatings, and viscous products. In short, our sanitary pigging system is extensively used by famous companies.

Hyperfore - 3-Way Piggable Diverter Valve

The piggable valve 3 channels are distributed at 120 °. As a result, pigging can start either from one starting point to the other two destinations, or from two starting points to one destination. Also, the product can be transferred smoothly. Meanwhile, it’s sanitary design makes no cleaning dead space . Above all, HYPERFORE 3-way diverter valve is robust and reliable,and maintenance frequency is very low, it is faster and more efficient than a piggable diverter panel.

Hyperfore - Sanitary Manual Pigging System

HYPERFORE manual pigging system is an economical and hygienic pipeline product recovery equipment. Chiefly, it includes manual launcher, manual receiver, a pig (pigging projectile )and other piggable components. In addition, it is mainly applied to household liquids, cosmetics, detergent, pet food industries and so on. It is fit for customers who want to save cost or do not pig the pipeline frequently. The payback of the manual system (product recovery system) is fast. It is cost-efficient equipment. it is also a good match for manual operation pipeline pigging and semi-automatic pipeline pigging.

Hyperfore - Aseptic Pigging System

In fully automated processes in the food and beverage industry the cleaning procedure is of equal importance to production itself for hygienic reasons. Generally the cleaning procedures must take place cyclically; that is to say, the frequency is high, often daily to guarantee the required freedom from bacteria. However, HYPERFORE aseptic pigging system can recover high valued products out of the production lines. As the none dead space design makes it a guardian that the entire pigging system is sterile.Not only our aseptic pigging system is highly suitable as an automatic cleaning method for pipelines in sterile plants, but also it makes closed piping systems possible.

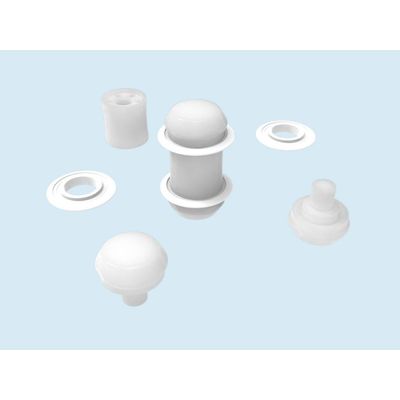

Pigging Systems -Hygienic (Sanitary) Pigs - One-Piece Tangent Pig

Hyperfore - One-Piece Dual- Shoulder Pig

The dual-shoulder hygienic pig, also one of the hygienic pigs, with its symmetrical design, features a relatively soft material and this symmetrical shape, ensuring a snug fit to the inner walls of pipelines, thus achieving optimal pigging efficiency. Compared to conventional pigging devices, it offers superior pigging performance, resulting in significantly lower product residue on the pipeline walls and improved product recovery rates, thereby enhancing pigging ROI. Of course, it requires a relatively higher driving force to propel the pig through the pipeline. It is available in various materials such as VMQ, EPDM, FKM, and more, making it suitable for pigging applications in the food, pharmaceutical, and other hygienic fluid product industries. Customization is also available to meet specific requirements.

Hyperfore - Model LIP - Dismantable Pig

The HYPERFORE dismantlable lip pig, designed with hygiene in mind, is expertly crafted using sanitary materials and features soft, elastic lip-shaped seals. These specially engineered lip-shaped seals not only extend the pig’s lifespan but also make it exceptionally well-suited for products containing particles, as evident in various pigging cases. One of the key advantages of this pig is its replaceable lip-shaped seals, which can be individually swapped out, ensuring cost-effective maintenance.

Hyperfore - Turbo Jet Jetting Pipeline Pig for Powder Pipeline

The Jetting Pipeline Pig, also called pigs for powder recovey, features six gas jet nozzles at its front end. As it traverses through the pipeline, it expels N2 from the jetting end to dislodge any powder adhering to the inner pipe walls. The airborne particles are then conveyed to the end of the pipe, achieving a more effective cleaning process. Following the pipe pig, it reduces the time and manpower required for subsequent cleaning.

Pigging Systems - Pigging Products

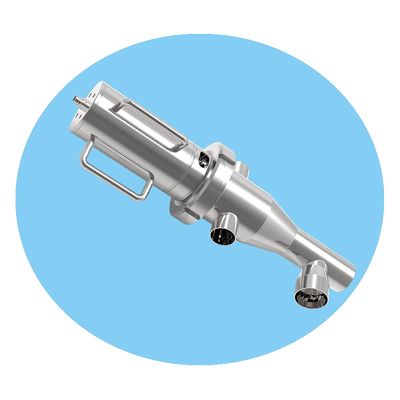

Hyperfore - Cyclone Separator

When the pig is going back to the launcher from the receiver, the material to be discharged is a mixture of gas and liquid. However, when the gas-liquid mixture is discharged from the pipeline, the mixture will splash all over the surrounding, and cause environmental pollution. So as to prevent this from happening, a cyclone separator is required. As a result, the gas will let out from its upper outlet, and the liquid will flow out from its bottom outlet, and there will not be splashing any more.